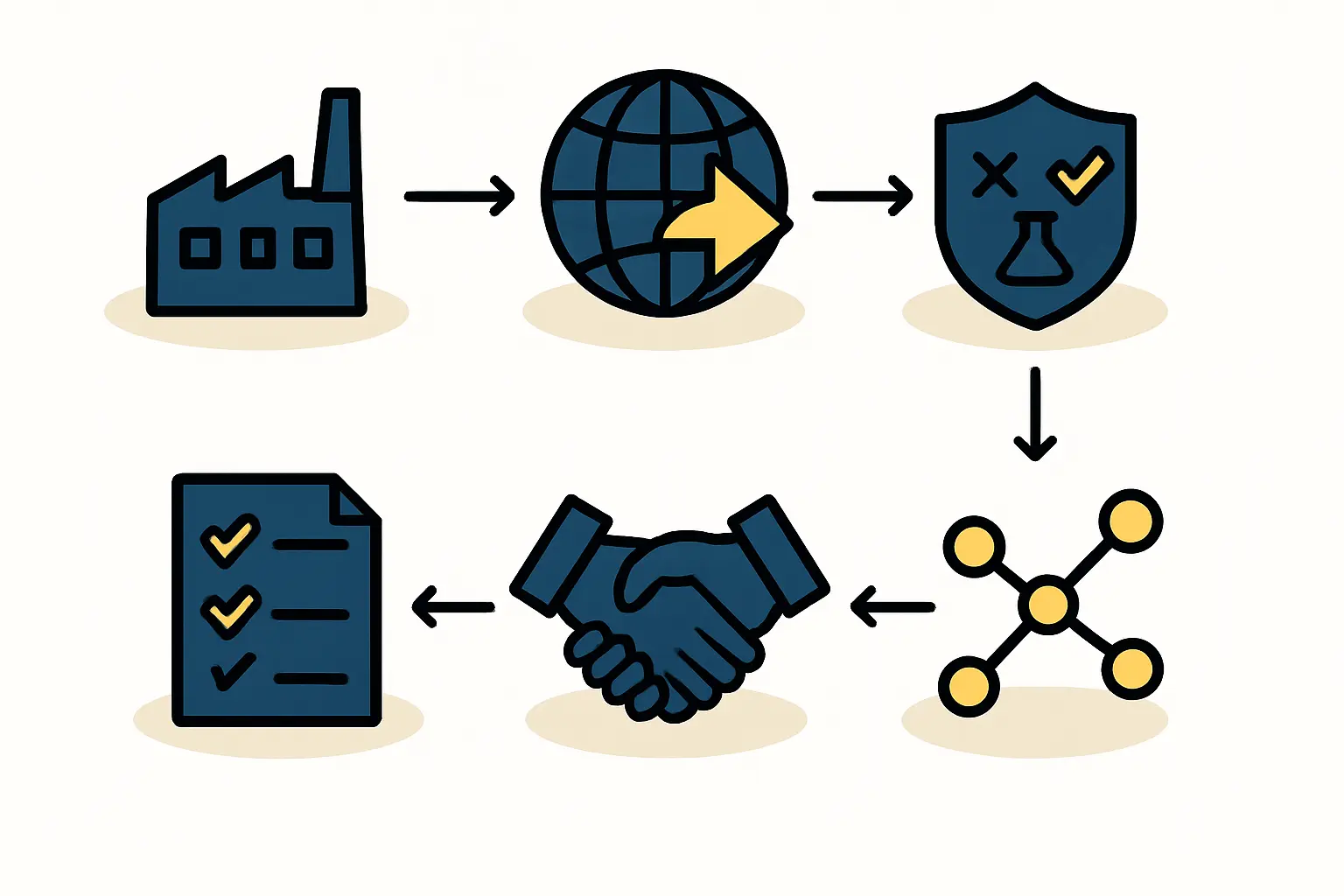

Establishing a solar module factory in Bangladesh is a compelling prospect. The nation has significant ambitions in renewable energy, backed by government support and a growing domestic market. For many entrepreneurs, however, the ultimate goal isn’t just to serve local needs but to create a global footprint by exporting high-quality solar modules.

This transition from local producer to global exporter presents a unique set of challenges. While building a solar panel is a technical achievement in itself, manufacturing one that can be legally and successfully sold in Europe, North America, or the Middle East requires a much higher level of strategic planning. Success hinges on one critical factor: provable, internationally recognized quality. This guide breaks down the essential requirements for transforming a Bangladeshi solar factory into a competitive international supplier.

Table of Contents

The Global Market: Opportunity and Obstacles

Bangladesh’s solar energy sector is expanding rapidly. Initiatives by organizations like the Infrastructure Development Company Limited (IDCOL) and the Sustainable and Renewable Energy Development Authority (SREDA) have created fertile ground for solar manufacturing. Thanks to its strong industrial base and favorable labor conditions, the country is well-positioned to become a key player in the global solar supply chain.

However, the international market runs on trust, and that trust is built through standardized testing and certification. An entrepreneur can produce a functionally perfect solar module, but without the correct certifications, it cannot enter most regulated markets. The primary obstacle isn’t a lack of manufacturing capability, but a gap in understanding and implementing the quality and documentation standards that global buyers demand.

Core Quality Certifications: The Keys to Market Access

Certifications are the universal language of quality and safety in the solar industry, assuring distributors, installers, and financiers that a module will perform reliably and safely over its lifespan. For a Bangladeshi manufacturer, obtaining the right certifications is the first and most crucial step toward building an export business.

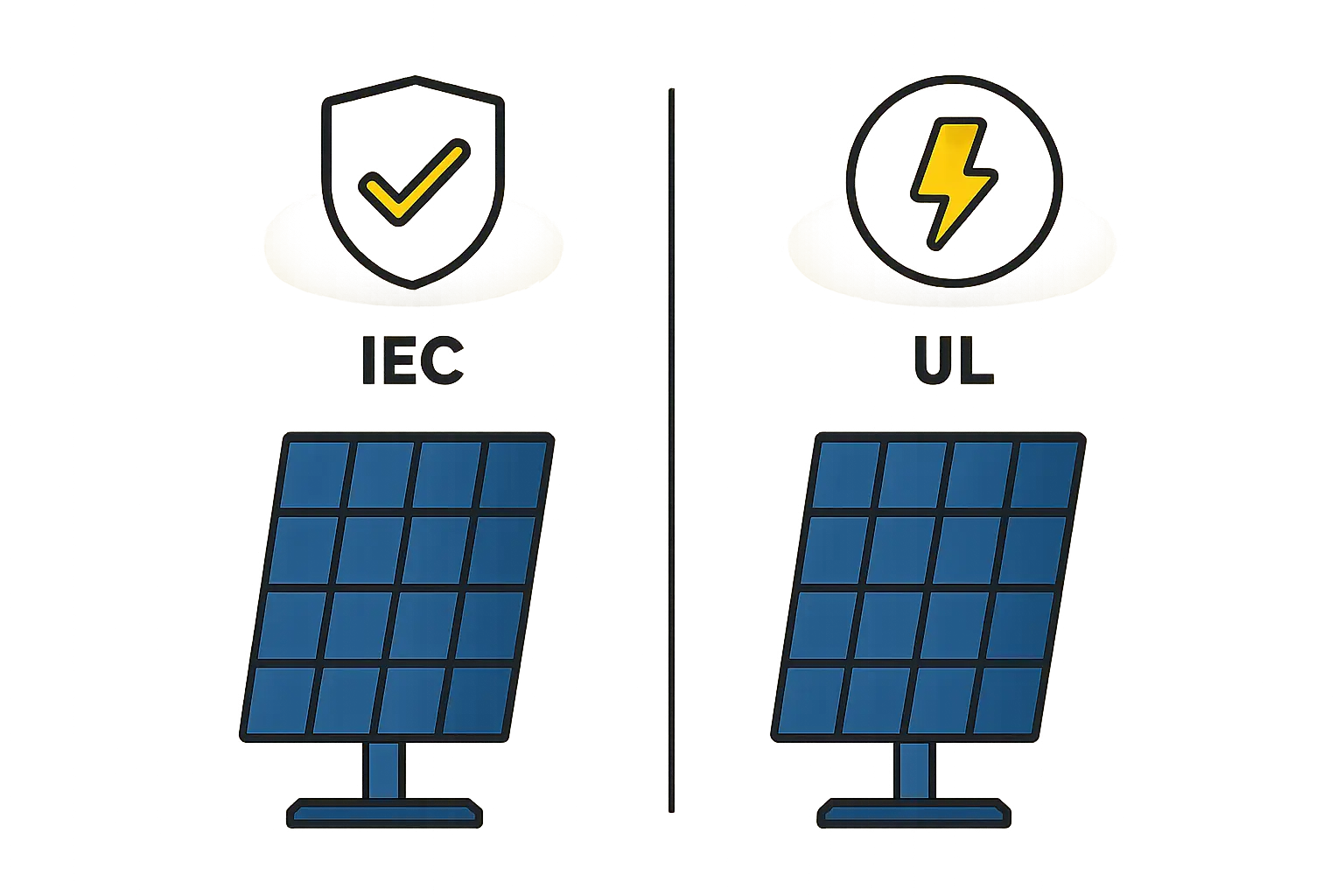

IEC Standards: The Global Benchmark

The International Electrotechnical Commission (IEC) provides the most widely accepted standards for solar modules worldwide, especially in Europe, Asia, Australia, and many parts of the Middle East and Africa.

-

IEC 61215 (Performance): This standard tests the design and performance of crystalline silicon terrestrial photovoltaic (PV) modules. It subjects modules to a battery of stress tests, including thermal cycling, humidity-freeze tests, UV exposure, and mechanical load testing. Passing this certification proves that a module is durable and will perform as expected under a wide range of environmental conditions.

-

IEC 61730 (Safety): This standard covers safety qualifications for PV modules, ensuring the product is safe from electrical shock, fire hazards, and personal injury throughout its lifetime. Tests include insulation resistance, wet leakage current, and impulse voltage. This certification is non-negotiable for mitigating liability and ensuring market acceptance.

Obtaining these certifications is a rigorous process. It can take several months and involves sending sample modules to an accredited third-party laboratory.

UL Certification: Unlocking the North American Market

For manufacturers aiming to export to the United States or Canada, UL certification is mandatory. Underwriters Laboratories (UL) is a global safety certification company, and its standards are the benchmark for electrical products in North America. The equivalent standard to IEC 61730 is UL 61730. While it has significant overlap with the IEC standard, it includes key differences in testing protocols and requirements that must be met. Attempting to enter the North American market without a UL mark is practically impossible.

Beyond the Certificate: Building a System of Quality

Certification is a result, not the starting point. It’s the outcome of a robust internal quality management system that governs every stage of manufacturing. International buyers, and the auditors they often employ, view this system as proof of a reliable long-term partner.

A Verifiable Bill of Materials (BOM)

The quality of a finished solar module is only as good as the quality of its components. A common challenge for new manufacturers in emerging markets is the inconsistent quality of locally sourced raw materials. Establishing a reliable supply chain for A-grade materials like solar cells, EVA encapsulant, backsheets, and junction boxes is therefore essential.

A detailed and verifiable Bill of Materials (BOM) is a manufacturer’s first line of defense against production failures and will be scrutinized during any serious due diligence.

A Calibrated and Controlled Production Line

Even with the best materials, inconsistent production will lead to defects and certification failures. A turnkey solar module production line from an experienced engineering partner ensures that each machine—from the stringer to the laminator and sun simulator—is properly calibrated and integrated.

Experience from numerous turnkey projects shows that precise control over parameters like soldering temperature and lamination pressure separates a high-performance module from a potential field failure.

Implementing a Quality Management System (QMS)

A formal QMS, such as ISO 9001, provides the framework for ensuring consistency and continuous improvement. It documents procedures for everything from receiving raw materials to final product inspection, packaging, and handling customer complaints. For leaders without a technical background, a QMS offers a structured way to enforce quality standards throughout the organization.

Navigating Export Procedures and Logistics

Once a product is certified and manufactured to a high standard, the final step is navigating the logistics of exporting. This involves:

-

Customs Documentation: Preparing all necessary paperwork, including commercial invoices, packing lists, certificates of origin, and proof of certification (IEC/UL).

-

Packaging and Shipping: Ensuring modules are packaged securely to prevent cell micro-cracks or other damage during transit. The packaging itself must often meet the standards of the destination country.

-

Understanding Tariffs and Trade Agreements: Researching the import duties and taxes for each target market is essential for accurate pricing and financial planning.

A manufacturer in Bangladesh, for example, must be prepared for the logistical and documentary scrutiny that comes with shipping to a port in Rotterdam, Houston, or Jeddah.

Frequently Asked Questions (FAQ)

Q: How long does it typically take to get IEC or UL certification?

A: The entire process—from preparing documentation and sample modules to completing tests and receiving the final certificate—typically takes six to nine months. It is critical to factor this timeline into your business plan.

Q: Can I export to any country without these certifications?

A: While it is possible to sell to smaller, unregulated markets without formal certification, this severely limits your market reach and brand reputation. Serious distributors and large-scale project developers will almost always require recognized international certifications.

Q: Is it better to source all materials locally in Bangladesh?

A: While sourcing locally can reduce costs and lead times, it is vital that local suppliers meet the stringent quality requirements for an export-grade module. Many successful manufacturers use a hybrid approach, sourcing components like aluminum frames locally while importing critical, certified components like solar cells and specialized polymers.

Q: What is the most common mistake new exporters make?

A: The most common mistake is focusing only on the final product test instead of building a robust quality management system from day one. Certification should be the proof of an existing quality system, not the entire goal.

Your Path to Becoming a Global Supplier

For entrepreneurs in Bangladesh, the opportunity to export solar modules is significant. Success, however, isn’t built on manufacturing alone. It rests on a foundation of internationally recognized quality, proven through certification and backed by a disciplined production process.

By understanding these requirements early, business leaders can strategically plan for global market entry. This involves selecting the right technology, establishing a reliable supply chain, and embedding quality control into every step of the operation. With the right preparation, a solar manufacturing business in Bangladesh can confidently compete on the world stage. For those ready to begin this journey, developing a comprehensive solar manufacturing business plan is the essential next step in turning global ambitions into reality.