When considering a new venture, an investor typically starts by evaluating assets like capital, technology, and market access. But in a specialized industry like solar module manufacturing, the most critical asset is human capital.

For an entrepreneur looking to establish a production facility in Barbados, the initial assessment might seem paradoxical. The nation boasts a literacy rate of over 99% and a robust education system, yet it has a limited history in advanced industrial manufacturing.

This situation is not a barrier; it’s a strategic opportunity. The challenge isn’t a lack of capable individuals, but a shortage of specific technical experience. This article provides a framework for evaluating the Barbadian labor market and outlines a proven process for developing a skilled local workforce ready to operate a modern solar panel factory.

Table of Contents

The Barbadian Labor Landscape: Strengths and Considerations

Barbados has long cultivated a skilled workforce, traditionally focused on tourism, international business, and finance. The government’s recent strategic pivot towards a green economy, exemplified by initiatives like the National Transformation Initiative (NTI), signals a clear commitment to reskilling its people for future industries, including renewable energy.

Key Strengths for Investors:

- High Educational Attainment: A workforce with strong literacy and numeracy skills can absorb technical training more quickly and effectively. Institutions like the University of the West Indies (UWI) at Cave Hill and the Samuel Jackman Prescod Institute of Technology (SJPI) produce a steady stream of educated and technically-inclined graduates.

- Government Support: National policy is increasingly aligned with sustainable development. This creates a favorable environment for training programs and public-private partnerships aimed at building a green-collar workforce.

- English Proficiency: As the official language, English eliminates communication barriers in training, documentation, and management—a significant advantage for international projects.

The primary challenge is the gap between general academic education and the specific, hands-on skills required for photovoltaic manufacturing. Bridging this gap is an expected and essential step in any project plan for a solar panel factory in a new market.

Analyzing Labor Availability and Costs

A typical semi-automated solar module production line with a capacity of 20-50 MW per year requires a team of approximately 25 to 35 employees. These roles fall into three main groups:

-

Operators (15-20): Responsible for running individual machines like stringers, laminators, and testers. Candidates can be sourced from any sector that demands attention to detail and adherence to process.

-

Technicians & Quality Control (5-8): These roles demand greater technical aptitude, often with a background in electronics, mechanics, or training from a vocational institute like SJPI. They handle machine maintenance, troubleshooting, and quality assurance checks.

-

Management & Administration (3-5): Includes the plant manager, a production supervisor, logistics personnel, and administrative staff.

Labor Cost Structure

As of 2023, the minimum wage in Barbados is BDS$9.25 (approximately US$4.63) per hour. While this provides a baseline, skilled and semi-skilled manufacturing roles will command higher wages. A realistic budget must account for competitive salaries to attract and retain talent. For instance, an experienced technician can expect a salary two to three times the minimum wage.

These labor costs, while higher than in some parts of Asia, are often competitive for the Caribbean and the Americas. When developing a financial forecast, labor is a key operating expense that influences the total investment needed for long-term viability.

Bridging the Skills Gap: A Framework for Workforce Training

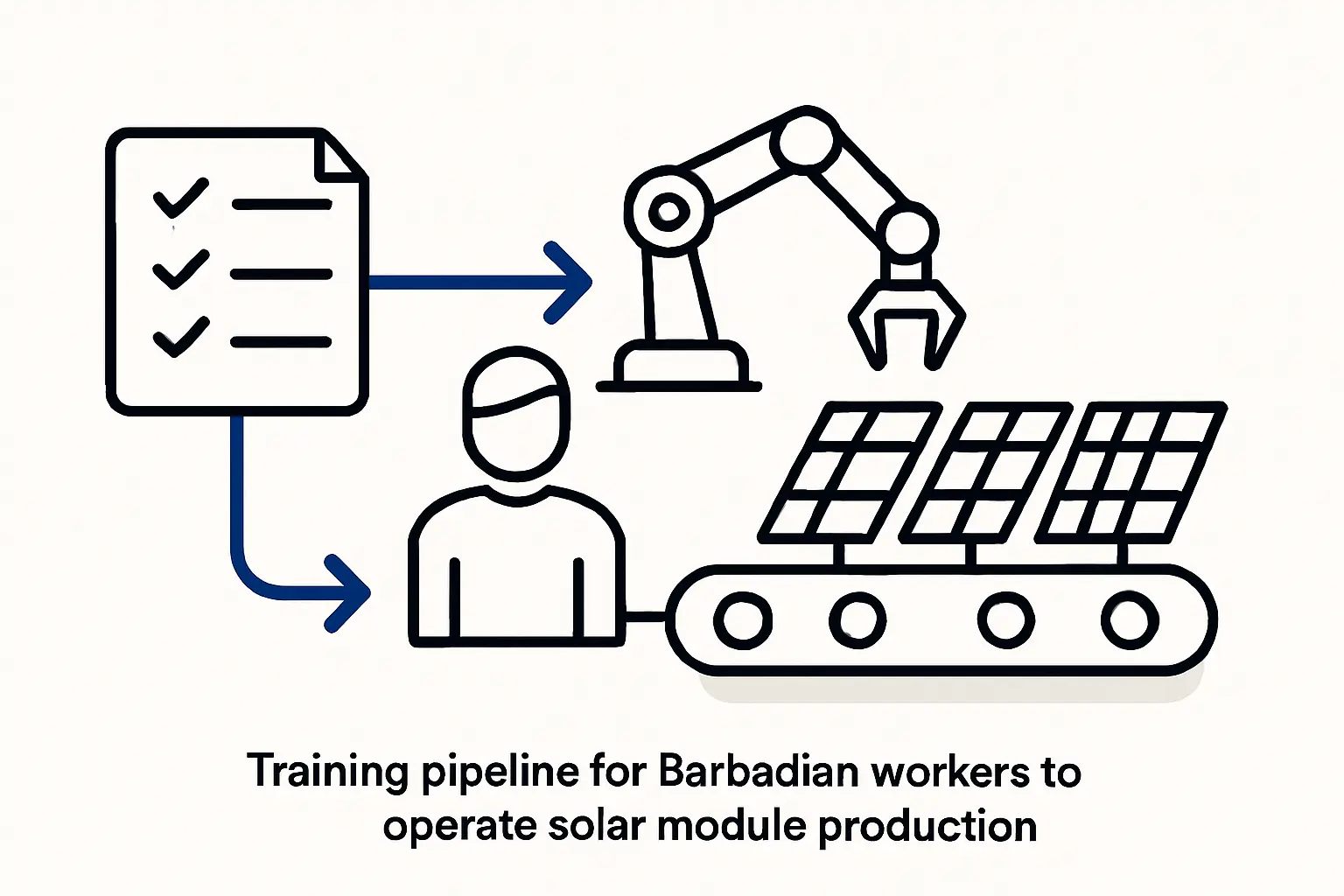

The success of a new solar factory hinges on transforming motivated local individuals into a proficient technical team. Experience from J.v.G. Technology turnkey projects across emerging markets shows that a structured, multi-phase training program is the most effective approach.

Phase 1: Sourcing and Aptitude-Based Selection

Instead of seeking non-existent “solar manufacturing experience,” the focus should be on identifying candidates with the right aptitudes. Look for individuals with a background in assembly, electronics repair, or any field demanding manual dexterity and precision. A well-designed screening process can identify high-potential candidates ready for training.

Phase 2: Foundational and Theoretical Training

Before any hands-on work, the core team begins with classroom-based learning. This foundational stage covers:

- Photovoltaic Basics: How solar cells work and how modules are constructed.

- Quality Standards: Understanding IEC/UL certification requirements and the importance of each production step.

- Material Handling: Proper procedures for managing delicate components like solar cells and glass.

- Safety Protocols: Ensuring a safe working environment around industrial machinery.

Phase 3: Hands-On Equipment Training

This critical phase is typically led by experienced engineers from the equipment supplier. The local team receives direct, on-site instruction for each piece of production equipment. The training is practical and goal-oriented:

- Operators learn the step-by-step process for their specific station.

- Technicians are taught routine maintenance, calibration, and troubleshooting.

- Quality control staff learn to use testing equipment like sun simulators and electroluminescence (EL) testers.

Precision and attention to detail are key skills developed during hands-on equipment training.

This hands-on process builds confidence and competence, ensuring the local team can independently manage production after the initial setup and commissioning period.

Building a Sustainable Local Team for Long-Term Success

The goal of training extends beyond initial operational readiness to building a sustainable local enterprise. A key strategy is to identify potential leaders within the initial cohort—individuals who can be developed into supervisors and future plant managers.

By creating clear career progression paths and investing in continuous skill development, a new factory can become a premier employer in the region. This approach not only helps retain top talent and counteract the risk of “brain drain” but also builds a resilient organization capable of adapting to new technologies and market demands. Ultimately, a well-trained, motivated local workforce is the engine that drives long-term profitability and contributes meaningfully to Barbados’ economic diversification.

Frequently Asked Questions (FAQ)

How many employees are typically needed to start a small solar factory?

For a semi-automated production line with an annual capacity of around 50 MW, a workforce of 25 to 35 employees—including operators, technicians, and administrative staff—is standard.

What are the most critical roles to hire first?

The first key hires should be the Plant Manager and a Lead Technician. These individuals will be instrumental in the project setup phase, participating in equipment selection, factory layout planning, and overseeing the training of the broader team.

How long does workforce training usually take?

A comprehensive training program for a new team typically spans four to six weeks. This includes about one week of theoretical instruction followed by three to five weeks of intensive, hands-on training on the actual production equipment during its installation and commissioning.

Is it necessary to hire foreign experts for the long term?

Typically, foreign experts (usually from the turnkey solution provider like J.v.G.) lead the initial training and production ramp-up. The primary objective is to transfer knowledge effectively, enabling the local team to assume full operational control within a few months. Long-term reliance on expatriate staff is generally not necessary or cost-effective.

How does labor and training fit into the overall business strategy?

Workforce planning, recruitment, training, and cost analysis are fundamental to a comprehensive business plan. A detailed human resources strategy demonstrates foresight to potential investors and financial institutions, assuring them of a viable plan to turn capital investment into a productive operation.