For an entrepreneur planning a solar module factory in Benin, the focus naturally falls on machinery, materials, and labor. Yet, one fundamental input can determine the success or failure of the entire operation: a stable, continuous supply of electricity.

While Benin is making strides in its energy sector, the public grid still poses significant challenges for power-intensive industries like solar panel manufacturing. Overlooking this critical infrastructure can lead to costly production failures and operational downtime.

Table of Contents

The Reality of Benin’s Electrical Grid for Industrial Users

Effective planning starts with a clear understanding of Benin’s national power infrastructure. According to recent energy sector analyses, the country grapples with the dual challenges of high costs and an inconsistent supply.

Key characteristics of Benin’s grid include:

-

High Import Dependency: Benin imports approximately 80% of its electricity, primarily from Nigeria, Ghana, and Côte d’Ivoire. This reliance on external sources makes the supply vulnerable to cross-border transmission issues and regional energy politics.

-

Elevated Tariffs: At roughly USD 0.25 per kilowatt-hour (kWh), industrial electricity tariffs in Benin are among the highest in West Africa. These costs directly impact a manufacturing plant’s operating expenditures and profitability.

-

Frequent Disruptions: The national grid, managed by the Société Béninoise d’Énergie Électrique (SBEE), is prone to frequent power outages, voltage fluctuations, and load shedding. For a residential user, this is an inconvenience; for a high-precision manufacturing line, it’s a critical operational risk.

These factors create an environment where relying solely on the public grid for 24/7 factory operations is not a viable strategy.

Why Continuous Power is Non-Negotiable in Solar Module Production

Solar module manufacturing involves several stages where a sudden loss of power can be catastrophic, destroying materials and derailing production schedules.

The Lamination Process

A laminator is a critical machine that uses heat and pressure to bond the layers of a solar panel (glass, EVA encapsulant, solar cells, and backsheet) into a durable unit. A typical cycle takes 15-20 minutes. If power is cut mid-cycle, the machine stops, and the entire batch of modules inside is often irreversibly damaged, resulting in a significant loss of materials.

Automated Cell Stringing

Modern stringers are high-speed, precision machines that solder solar cells into strings. A power interruption can bring these machines to an abrupt halt, potentially damaging delicate cells and requiring time-consuming recalibration by a technician. The resulting downtime translates directly into lost output.

Process Consistency and Quality

A steady power supply ensures all equipment operates within specified parameters. Voltage fluctuations can affect testing equipment like sun simulators and EL testers, leading to inaccurate quality control readings and potentially compromising the product’s final certification.

A single power outage of just a few minutes can lead to thousands of dollars in wasted materials and hours of lost production, making a plan for 100% power uptime a foundational requirement.

Strategies for Achieving an Uninterrupted Power Supply

To mitigate the risks of an unstable grid, a factory needs its own reliable backup power system. The most common and proven solutions combine established and modern technologies.

Primary Solution: Diesel Generators

In regions with an unreliable grid, a diesel generator remains the standard, most dependable backup power solution for industrial applications. It provides a stable source of electricity capable of running the entire factory load during a public grid outage.

Key considerations for a generator include:

-

Correct Sizing: The generator’s capacity (measured in kVA or kW) must be calculated to handle the factory’s entire peak electricity demand. An undersized generator will fail, while an oversized one is inefficient.

-

Automatic Transfer Switch (ATS): An ATS automatically detects a grid failure and signals the generator to start, seamlessly switching the factory’s power source from the grid to the generator with minimal interruption.

-

Fuel and Maintenance: A robust plan for diesel fuel storage and regular generator maintenance is essential to ensure it is ready to operate at a moment’s notice.

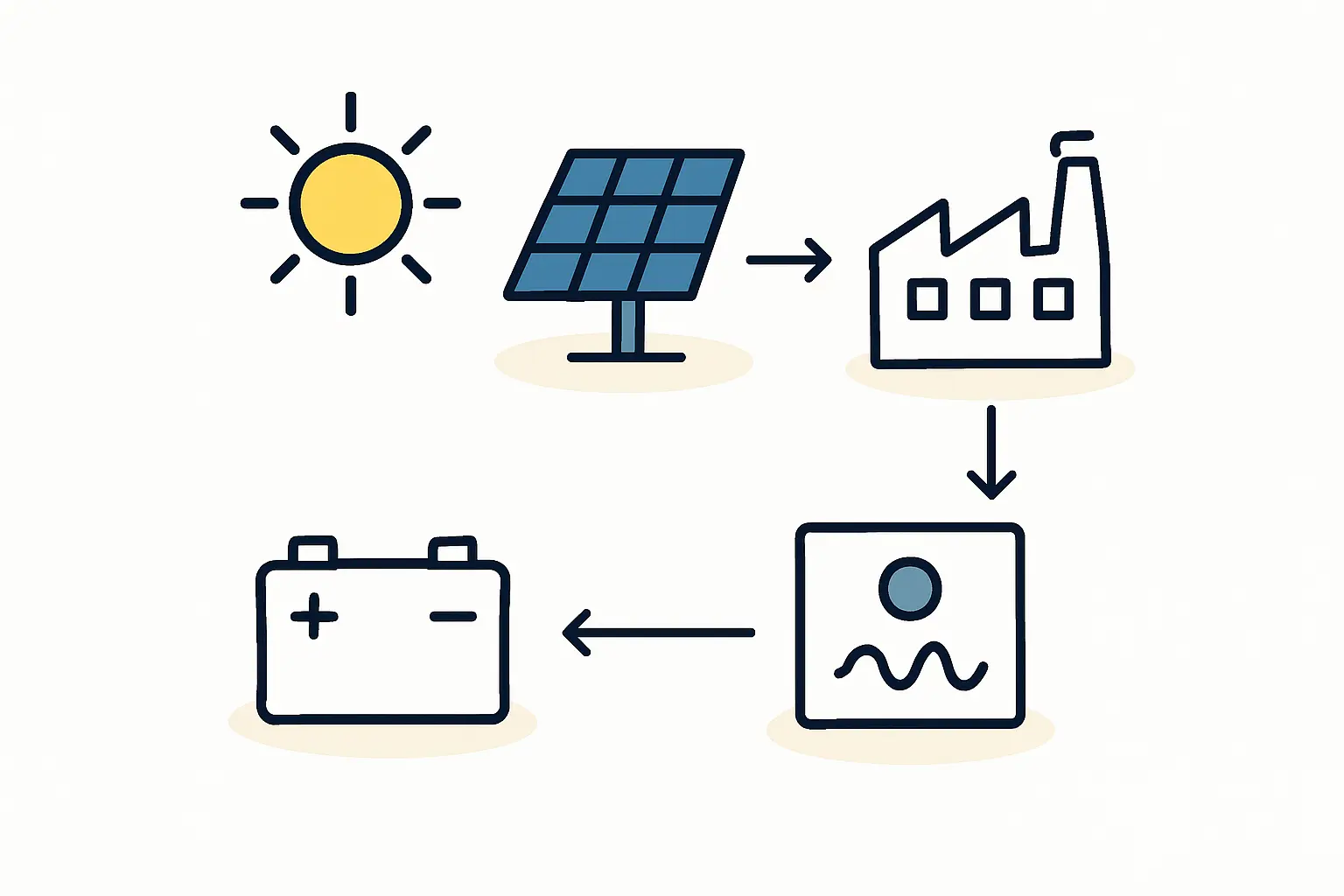

Complementary Solution: Solar Power with Battery Storage (BESS)

An increasingly attractive option, especially for a solar module factory, is to use the very product it creates to power its own operations. A large-scale solar array, typically on the factory roof, can be paired with a Battery Energy Storage System (BESS).

This system offers several benefits:

-

Reduce Electricity Bills: During daylight hours, the solar array can power the factory directly, significantly cutting reliance on the expensive public grid.

-

Provide Short-Term Backup: The BESS provides instantaneous power the moment the grid fails, bridging the short gap until the diesel generator starts up.

-

Lower Diesel Consumption: With sufficient battery capacity, the BESS can handle shorter outages on its own, saving on diesel fuel costs.

While the initial investment for a BESS is higher than for a generator alone, it offers long-term savings on energy costs and promotes greater energy independence.

Integrating Power Solutions into Factory Design

The most effective power strategy is one that’s integrated into the factory design from the very beginning. The electrical requirements of all machinery—from the stringer to the laminator and testing equipment—must be calculated to design a holistic power system. This system is a core component of any turnkey solar production line. Experience from J.v.G. turnkey projects shows that integrating the power solution during initial layout and financial planning is crucial to prevent costly retrofits and operational surprises down the line.

Frequently Asked Questions (FAQ)

-

How large of a generator does a typical small-to-medium solar factory need?

For a 20 MW to 50 MW production line, the power demand typically requires a generator in the 250 kVA to 500 kVA range. A detailed load analysis of the specific equipment list is necessary to determine the precise size. -

Can I run my factory entirely on a generator to avoid the public grid?

While technically possible, it’s generally not economically viable. The cost of diesel fuel to run a factory 24/7 would be extremely high. The generator is best used as a backup system for grid outages. -

Is a solar and battery system enough to replace a diesel generator?

To guarantee 100% uptime for 24/7 manufacturing, a diesel generator remains the most reliable primary backup. A BESS is an excellent complement for saving money and handling short interruptions, but it may not be sufficient for multi-day outages or long periods of low solar irradiation. -

How does this affect the initial investment budget?

Entrepreneurs must include the cost of a generator, an ATS, and initial fuel storage in their business plan. This capital expenditure is as essential as the production machinery itself, and overlooking it creates a significant and predictable risk to the entire investment.

Conclusion: Securing Your Investment’s Foundation

In Benin’s promising yet challenging energy landscape, a stable power supply isn’t just an operational detail—it’s a strategic necessity. Acknowledging the public grid’s limitations and investing in a robust backup power system—such as a correctly sized diesel generator supplemented by solar and battery storage—is fundamental to protecting your investment.

With this foresight, the factory can maintain continuous production, uphold quality standards, and operate profitably, turning a potential vulnerability into a competitive advantage.