An investor looking at Burkina Faso sees two distinct realities. One is a nation with some of the world’s highest solar irradiation levels, averaging 5.5 to 6.5 kWh/m²/day—a vast opportunity to address a national energy deficit while reducing reliance on expensive imported fossil fuels. The other, often highlighted in international news, is a reality of significant security challenges and political instability.

For the serious entrepreneur, navigating this landscape is not a matter of optimism, but of structure. Success hinges not on ignoring risks, but on understanding and managing them systematically. This article provides a professional framework for assessing and mitigating the non-market operational risks of establishing a solar module factory in Burkina Faso, transforming potential obstacles into manageable business variables.

Table of Contents

Understanding the Dual Reality of Burkina Faso’s Business Environment

The business case for local solar production in Burkina Faso is compelling. The government has expressed clear goals to increase the share of renewable energy, and local demand for reliable power is substantial. This potential, however, is set against a backdrop of profound operational challenges.

Since early 2022, the country has experienced two military coups, leading to its suspension from regional bodies like ECOWAS and the African Union. The security situation, particularly in regions outside the capital, is complicated by the presence of armed groups, which has displaced nearly two million people.

The Africa Center for Strategic Studies estimates that 40% of the nation’s territory remains outside direct state control. These factors do not nullify the investment opportunity, but they demand a higher level of diligence. An investor’s most critical tool is a robust operational risk management plan tailored to the specific context of the region.

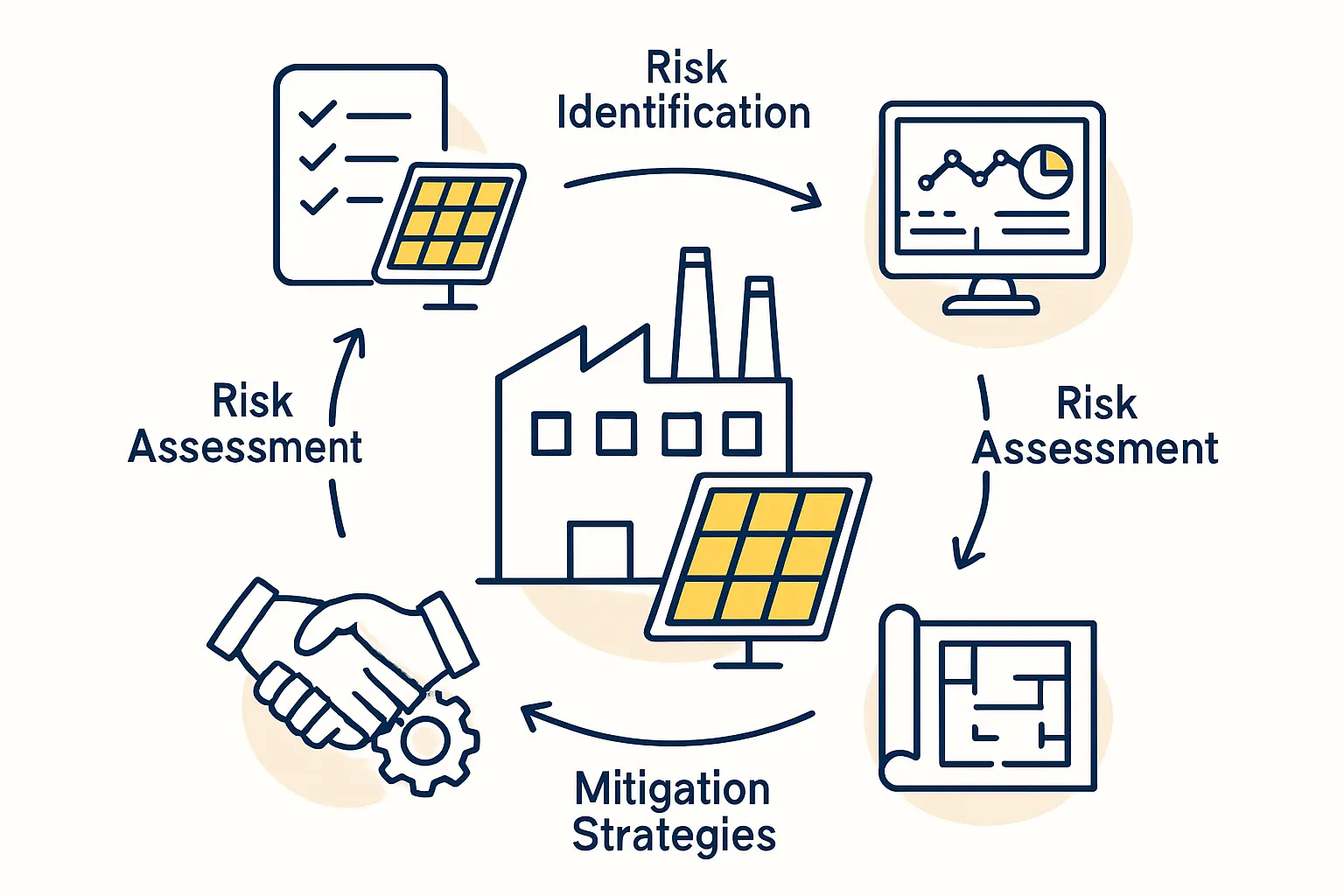

A Structured Framework for Operational Risk Management

Operational risk is the potential for loss resulting from inadequate or failed internal processes, people, and systems, or from external events. For a solar factory in Burkina Faso, managing this risk is fundamental to business continuity. A proven approach involves a continuous four-step cycle:

- Identify: Systematically identify potential threats to the operation, from political shifts and supply chain vulnerabilities to personnel safety.

- Assess: Evaluate each identified risk for its potential impact and likelihood. This assessment allows for prioritization, focusing resources on the most critical threats.

- Mitigate: Develop and implement strategies to reduce the likelihood or impact of an identified risk. These can range from physical security enhancements to financial instruments like insurance.

- Monitor: Given the dynamic operating environment, risks and mitigation strategies must be continuously monitored to adapt the plan as conditions change.

Key Risk Categories and Mitigation Strategies

Applying this framework, an investor can systematically prepare for the most salient challenges in Burkina Faso.

Political and Regulatory Instability

Risk Identification:

The recent history of military coups demonstrates the potential for sudden changes in government. This instability can trigger shifts in economic policy, force the renegotiation of investment agreements, and disrupt administrative processes such as customs clearance and permit renewals. Suspension from regional economic blocs can also impact trade and logistics.

Mitigation Strategies:

- Strengthened Legal Protections: Work with legal experts specializing in the region to structure investment agreements that are resilient to changes in government.

- Political Risk Insurance: Secure insurance policies that cover losses from events like expropriation, political violence, or currency inconvertibility.

- Strong Local Partnerships: Engage reputable local partners who have a deep understanding of the political landscape and can provide valuable counsel.

- Maintain Neutrality: Ensure the business operates with strict political neutrality, focusing solely on its commercial and developmental objectives.

Security Threats and Personnel Safety

Risk Identification:

The security situation—particularly the presence of armed insurgent groups—poses a direct threat to physical assets and, more importantly, to the safety of employees. These risks include potential attacks on facilities, kidnapping, and disruptions to transportation routes for staff and materials.

Mitigation Strategies:

- Strategic Site Selection: Locate the facility within or near the more secure perimeter of the capital, Ouagadougou, to significantly reduce direct security threats. A thorough site analysis must be a priority.

- Physical Security: A comprehensive security plan is non-negotiable. This includes perimeter fencing, controlled access points, professional guard services, and surveillance systems. The facility’s design should incorporate security principles from the ground up.

- Personnel Protocols: Implement strict security protocols for all employees, including secure transportation arrangements, journey management for any necessary travel, and regular safety training and drills.

- Contingency Planning: Develop detailed emergency response and evacuation plans in consultation with security experts.

Supply Chain and Logistical Disruptions

Risk Identification:

A solar module factory depends on a global supply chain for raw materials like solar cells, glass, and aluminum frames. Political instability can lead to border closures, while security issues can render key transport corridors unsafe, creating a significant risk of production stoppages from material shortages.

Mitigation Strategies:

- Increased Buffer Stocks: Maintain a larger-than-usual inventory of critical raw materials on-site. Holding three to six months of stock—rather than following the “just-in-time” standard common in Europe—provides a crucial buffer against disruptions.

- Diversified Logistics: Identify and vet multiple transportation routes and freight forwarders. Have contingency plans for shifting from road to air freight for critical components if necessary.

- Strong Local Logistics Partners: Work with experienced local customs brokers and logistics firms who can navigate administrative hurdles and provide real-time information on ground conditions. Establishing these resilient supply chains is a core component of the initial project phase, especially when setting up a turnkey manufacturing line.

Human Capital and Workforce Management

Risk Identification:

The general security situation can affect employee morale, attendance, and retention. Additionally, the local labor market may have skill gaps for the technical roles required in solar module manufacturing.

Mitigation Strategies:

- Investment in Training: Develop a comprehensive in-house training program to build the necessary technical skills within the local workforce. This investment fosters loyalty and creates a highly capable team.

- Prioritize a Secure Workplace: Create a visibly secure and stable work environment. This is one of the most effective ways to build employee confidence and ensure consistent operations.

- Enhanced Health and Safety: Implement health, safety, and environment (HSE) protocols that meet or exceed international standards, demonstrating a clear commitment to employee welfare.

The Business Case for Proactive Risk Management

Viewing risk management as a mere cost center is a critical mistake. In an environment like Burkina Faso, it is a strategic investment in the long-term viability and profitability of the enterprise. A detailed and credible risk management plan is often a prerequisite for securing financing from development banks and international investors, as it demonstrates a level of foresight and operational competence that is just as important as the factory’s technical specifications.

The resources allocated to security, supply chain buffers, and insurance are directly linked to the project’s resilience. While these measures increase initial investment costs, they are essential for protecting that investment over the long term.

Frequently Asked Questions (FAQ)

Q: Is it truly feasible to run a successful manufacturing operation in this environment?

A: Yes, but it requires a level of planning and operational discipline beyond standard European or North American practices. Several international companies in other sectors operate successfully in the region by prioritizing risk management. The key is preparation, not avoidance.

Q: How much should a business budget for security-related expenses?

A: This varies significantly based on the factory’s location, size, and the prevailing security climate. An investor should anticipate, however, that security costs could represent a notable portion of the operational budget, potentially between 5% and 15%.

Q: What is the role of a local partner in risk mitigation?

A: A well-vetted local partner is invaluable. They provide critical insights into the local political, cultural, and security context that an outside investor would struggle to acquire alone. They can help navigate bureaucracy, build community relations, and provide early warnings of emerging risks.

Q: How does this operating environment impact project insurance?

A: Insurance premiums, particularly for political risk and business interruption, will be higher than in more stable markets. However, presenting the insurer with a comprehensive, professional risk mitigation plan can help manage these costs and secure favorable terms.

Conclusion: Building a Resilient Enterprise

The opportunity to build a solar module factory in Burkina Faso is significant, offering the chance to meet a critical need while building a profitable enterprise. The operational challenges, however, are equally significant. Success hinges on a clear-eyed, methodical approach to risk.

A structured framework to identify, assess, mitigate, and monitor non-market risks allows an investor to move forward with confidence. This process begins long before the first machine is installed; it starts with a deep understanding of the environment and a commitment to building a resilient operation—from the initial factory layout and design to the day-to-day management of the facility. With the right preparation and guidance, the immense potential of solar energy in Burkina Faso can be responsibly and successfully unlocked.