Entrepreneurs planning to enter the solar manufacturing industry often start by researching the latest, most powerful modules available globally. Their instinct is to produce the largest, highest-wattage panels to compete on efficiency.

In a market like Burkina Faso, however, this instinct can lead to a fundamental mismatch between the product and the user’s actual needs. The most successful ventures aren’t built on replicating global trends, but on precisely meeting local demand.

This article explores how to develop a product strategy for a solar module factory tailored to the off-grid and mini-grid opportunities in Burkina Faso. It shows how analyzing the business environment shapes technical product design, ensuring that manufactured modules are not just powerful, but also practical, transportable, and well-suited to the region’s key applications.

Table of Contents

Understanding Burkina Faso’s Energy Landscape

Designing the right product starts with understanding the local environment. According to the International Energy Agency (IEA), over 600 million people in Africa lack access to electricity. For Burkina Faso, the national electrification rate is approximately 19%, dropping to a mere 7% in rural areas. This significant gap is not a barrier but the primary market opportunity, driven almost entirely by off-grid and mini-grid solutions.

These are not simply smaller versions of traditional power grids; they are distinct ecosystems with unique requirements:

- Off-Grid Systems: Standalone installations powering a single home, water pump, or business. They are self-contained, relying on battery storage or the direct use of generated power.

- Mini-Grids: Small, localized power networks that can supply an entire village, clinic, or school, operating independently from the national grid.

Burkina Faso benefits from excellent solar irradiation, making solar PV the most logical and cost-effective technology for closing this energy access gap. The challenge, then, lies not in the availability of solar energy, but in producing modules that fit the logistical and application-specific realities of the country.

The “Why” Before the “What”: Aligning Production with Market Demand

A comprehensive business plan for a solar factory begins with a deep analysis of the end customer’s needs. The World Bank notes that agriculture accounts for around 30% of Burkina Faso’s GDP and employs 80% of its workforce. This single statistic is a powerful indicator of where solar energy can make the most significant impact.

Instead of asking, “What are the most powerful modules we can make?” the strategic question becomes, “What problems are our customers trying to solve?” In Burkina Faso, the answers consistently point toward three core areas: agricultural productivity, rural electrification, and the power needs of small businesses and institutions.

Key Market Segments and Their Technical Requirements

A successful product strategy involves designing modules optimized for the dominant applications. In Burkina Faso, these differ from the typical residential rooftop or utility-scale projects seen in Europe or North America.

Agricultural Water Pumping

This is arguably the largest and most immediate market. Smallholder farmers require reliable water access for irrigation and livestock, which directly impacts their yields and income.

- System Profile: A typical solar water pump system for a small farm requires between 2 and 5 kW of power. It operates during the day, often without batteries, with the PV array directly powering the pump’s inverter.

- Technical Needs: The system’s voltage must match the pump inverter’s requirements. Modules need to be robust and durable enough to withstand a harsh, dusty environment with high ambient temperatures.

- Product Implication: The ideal module is easy to transport over rural roads and can be installed by a small team without heavy lifting equipment. A very large, heavy module (e.g., 600–700 Wp, over 35 kg) poses significant logistical and breakage risks. A more moderately sized module of 400–450 Wp is often far more practical for both transport and installation.

Rural Electrification (Solar Home Systems & Mini-Grids)

For households and communities, the priority is lighting, mobile phone charging, and power for small appliances and community services.

- System Profile: This segment ranges from small Solar Home Systems (SHS), often using panels under 100 Wp, to mini-grids for villages, schools, or health clinics that can be several kilowatts in size.

- Technical Needs: For SHS, efficiency in a small form factor is key. For mini-grids, reliability and longevity are paramount, as these systems provide essential services. The design must ensure consistent performance, even in high-temperature conditions.

- Product Implication: A manufacturer could consider a diversified portfolio. While primary production could focus on the 400–450 Wp modules for pumps and mini-grids, a smaller, secondary line could be configured for the sub-100 Wp SHS market, which has different cell and material requirements.

Small Commercial & Institutional Use

Small businesses, telecom towers, and local administrative offices represent a growing commercial and industrial (C&I) segment.

- System Profile: These systems power refrigeration, grain mills, communication equipment, and office essentials. They often require reliable, 24/7 power, necessitating battery storage.

- Technical Needs: The module array must be designed to sufficiently charge a battery bank while powering daytime loads. System durability is critical, as business operations depend on it.

- Product Implication: The 400–450 Wp module designed for agricultural use is also an excellent fit here. Its versatility makes it a strong candidate for standardization, simplifying the manufacturing process and supply chain.

Translating Market Needs into Manufacturing Specifications

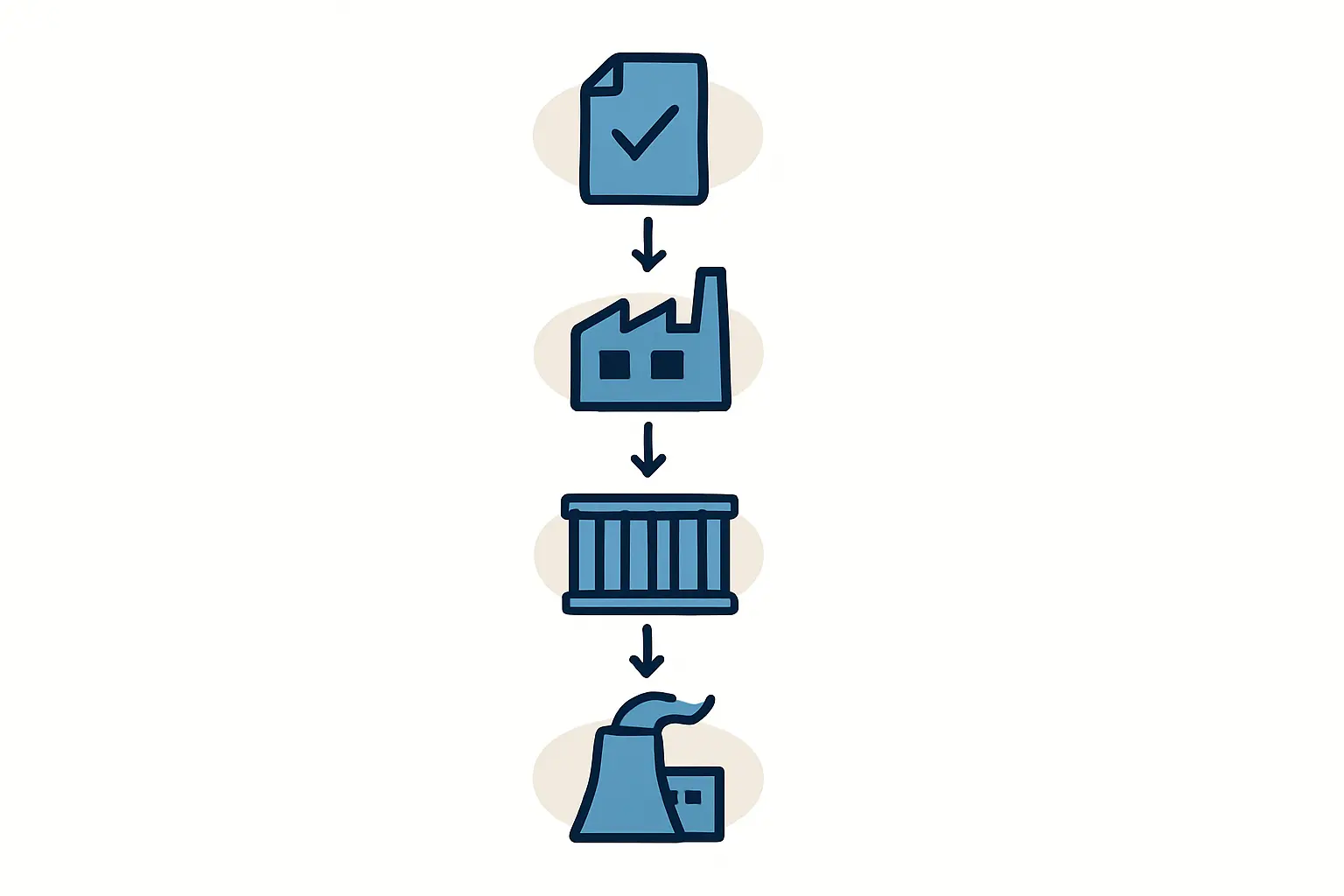

Understanding the market is the first step; the next is to translate those insights into a concrete manufacturing plan. The decision to produce a 450 Wp module instead of a 650 Wp module has direct consequences for the factory setup.

This choice influences:

- The Bill of Materials (BOM): Affects the size of glass, backsheet, and aluminum frames required.

- Cell Technology: Dictates the size and type of solar cells to be sourced (e.g., M6, M10, or G12 wafers).

- Machinery Configuration: The stringer, laminator, and framing station must all be calibrated for the chosen module dimensions. The full list of solar panel manufacturing machines depends on this core product decision.

A turnkey solar manufacturing line is often the most efficient way to ensure all equipment is perfectly synchronized to produce the target module. Based on experience from J.v.G. turnkey projects, aligning the machinery with a well-defined product strategy from day one is critical for minimizing setup time and production errors. This focused approach also clarifies the total investment needed to start a solar panel manufacturing business, as it removes ambiguity around equipment and material costs.

Frequently Asked Questions (FAQ)

Q: Why not just import cheaper modules from Asia?

A: While importing is an option, local manufacturing offers distinct advantages in a market like Burkina Faso. These include creating local employment, reducing transportation costs and damage risks over long distances, offering faster after-sales service and warranty support, and potentially benefiting from government incentives for local industry. Furthermore, a local producer can design products specifically for the regional climate and applications—a level of customization importers cannot offer.

Q: Is a 450 Wp module less advanced than a 650 Wp module?

A: Not necessarily. A module’s power output is primarily a function of its surface area and the efficiency of the cells inside. A 450 Wp module can use the exact same high-efficiency cell technology as a 650 Wp module; it is simply smaller. The choice is not about “advanced” versus “outdated” technology but about “fitness for purpose.” For off-grid applications with logistical constraints, a smaller, more manageable module is often the superior product.

Q: How does module design affect certification requirements?

A: All reputable solar modules must pass international certification standards, such as IEC 61215 and IEC 61730, to guarantee performance and safety. However, a manufacturer can go further by designing and testing for conditions specific to the Sahel region, such as high temperatures (Pmax temperature coefficient), high dust levels (soiling resistance), and high UV radiation. Designing for these factors creates a more reliable, premium product, even if the core certifications are the same.

Conclusion: From Market Insight to a Viable Business

Building a successful solar module factory in Burkina Faso—or any emerging market—begins long before the first machine is ordered. It starts with a product strategy grounded in the realities of the local economy, geography, and energy needs.

By focusing on practical, durable, and appropriately sized modules for high-demand sectors like agriculture and rural electrification, an entrepreneur can build a resilient business that meets tangible local needs.

An analysis of the business environment is not merely a preliminary step; it is the foundation for the factory’s entire technical and financial structure. This market-led approach transforms a manufacturing project from a speculative venture into a targeted solution for a clear and present need.