Imagine your new, state-of-the-art solar module factory is fully assembled and ready for production. The staff is trained and the power is on, but the assembly line remains silent. The reason? A critical shipment of solar cells and glass is stranded at a seaport over 1,400 kilometers away, caught in logistical delays.

This scenario is far from hypothetical—it’s a primary operational challenge for entrepreneurs establishing manufacturing facilities in landlocked countries. This article explores the specific logistical hurdles of importing essential raw materials, using the practical example of setting up a solar factory in Burundi. The journey from a global supplier to an inland factory floor highlights the challenges and strategic solutions fundamental to succeeding in such an environment.

Table of Contents

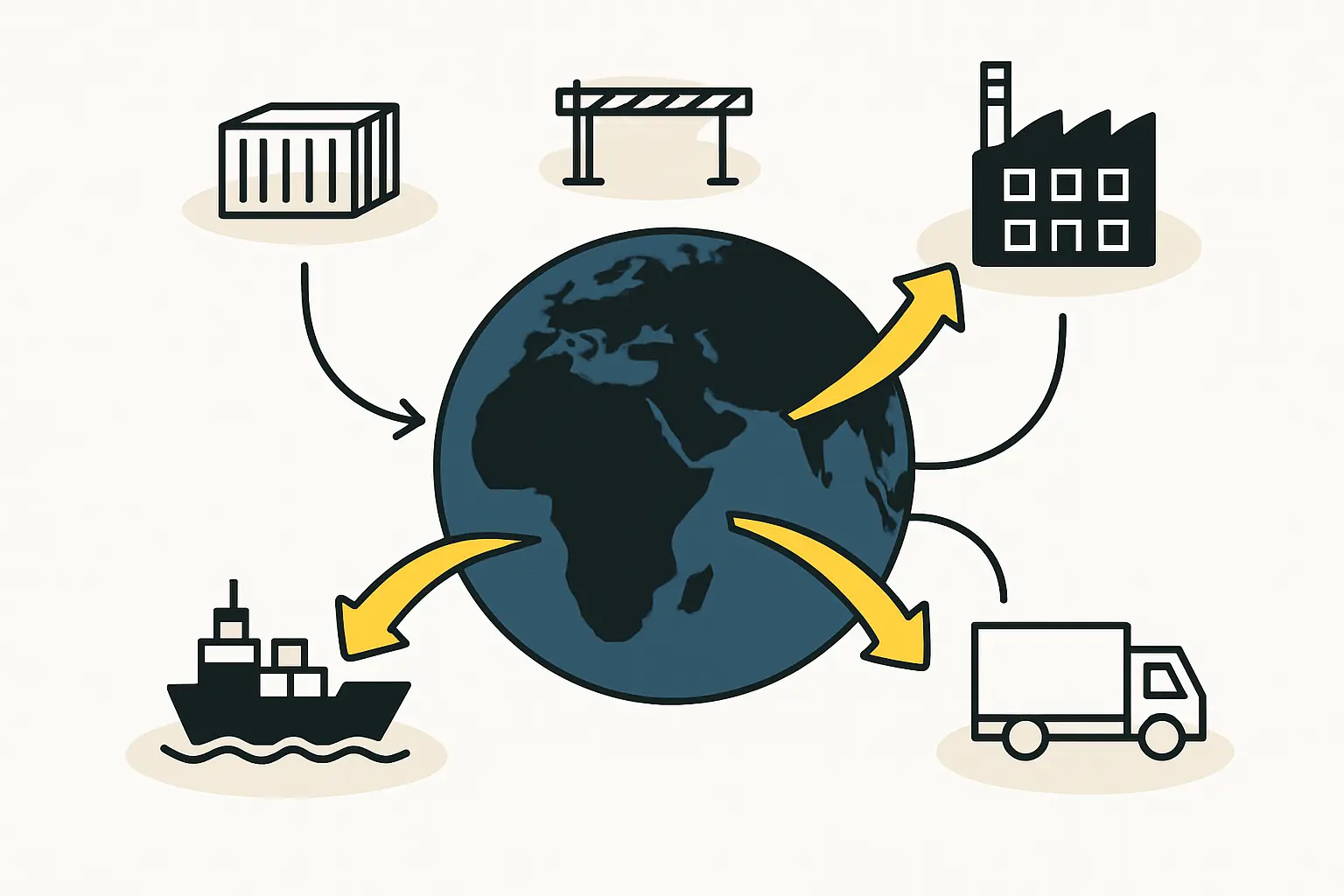

The Core Challenge: Connecting a Global Supply Chain to an Inland Factory

Solar module manufacturing is inherently dependent on a global supply chain. Key components such as solar cells, tempered glass, aluminum frames, and junction boxes are typically sourced from established industrial hubs, primarily in Asia. For a coastal nation, the journey ends at a local port.

But for a landlocked nation like Burundi in the heart of East Africa, the maritime journey is only the first step. The overland journey that follows—often spanning more than a thousand kilometers through neighboring countries—is where the most significant complexities arise. This last-mile challenge requires meticulous planning, as it involves multiple jurisdictions, modes of transport, and potential bottlenecks that can halt production and inflate costs unexpectedly.

Mapping the Journey: From Sea Port to Factory Door

An investor planning a factory in Bujumbura, Burundi, must first decide on a maritime gateway. The two most viable corridors for importing solar panel components are through Tanzania and Kenya, and each comes with its own set of variables.

The Dar es Salaam (Tanzania) Corridor

- This is the most direct and commonly used route for cargo destined for Burundi.

- Distance to Bujumbura: Approximately 1,400 kilometers.

- Typical Transit Time: 4 to 5 days by road transport.

- Considerations: While this route is shorter, the Port of Dar es Salaam and its road network can experience significant congestion. Delays in port clearance and truck availability are common operational risks that must be factored into any timeline.

The Mombasa (Kenya) Corridor

- Though a longer route, the Port of Mombasa offers a strategic alternative.

- Distance to Bujumbura: Approximately 1,700 kilometers.

- Typical Transit Time: 5 to 7 days by road transport.

- Considerations: The Port of Mombasa is recognized for its modern infrastructure and higher efficiency. The overland route, however, is more complex, potentially crossing through Uganda and Rwanda before reaching Burundi. Each additional border introduces another layer of customs procedures and potential delays.

The choice between these corridors is not static; it depends on current port conditions, political stability, road quality, and the expertise of the chosen logistics partner.

Three Critical Logistical Hurdles Every Investor Must Address

Beyond selecting a port, investors must navigate a series of complex challenges that can severely impact project budgets and timelines. Understanding these issues is the first step toward building a robust supply chain for your solar panel factory.

1. The Container Conundrum: Demurrage and Detention Fees

Shipping containers are the property of maritime carriers, who expect them to be returned promptly to keep them in global circulation. To enforce this, they apply two types of late fees:

- Demurrage: A fee charged for a full container that has not been moved out of the port within a stipulated number of free days.

- Detention: A fee charged for an empty container that has not been returned to the port within the allotted free days after being unloaded at its destination.

For an inland factory in Burundi, the round trip to collect a container, unload it, and return the empty unit can easily take longer than the 7 to 14 free days typically offered. The resulting detention fees can accumulate at rates of over USD 100 per day, per container, quickly turning a profitable venture into a loss-making one. This financial risk is one of the most underestimated aspects of launching a solar module business in a landlocked region.

2. The Risk of Transloading: To Strip or Not to Strip?

To mitigate the risk of detention fees, many importers use a strategy known as stripping or transloading the container at a bonded warehouse near the port. The cargo is unloaded from the maritime container and re-loaded onto locally registered trucks for the inland journey. This allows the expensive shipping container to be returned to the port immediately.

But this solution comes with its own trade-offs, which must be carefully weighed.

Strategy: Direct Transport

- Advantages: Reduced handling of cargo lowers the risk of damage, especially to fragile items like solar glass. The logistics are simpler with a single transport leg from the port.

- Disadvantages: High risk of incurring expensive detention fees. May be difficult to arrange, as some shipping lines are reluctant to let containers travel far inland.

Strategy: Port Transloading

- Advantages: Virtually eliminates the risk of detention fees. Offers greater flexibility in choosing overland transport providers.

- Disadvantages: Incurs added costs for labor, warehousing, and double-handling. Significantly increases the risk of damage to materials during the re-loading process.

3. Navigating the Paper Trail: Customs and Border Delays

Each border crossing between the seaport and the factory is a potential bottleneck. Incorrect or incomplete documentation can lead to days or even weeks of delays, disrupting the production schedule. While regional initiatives like One-Stop Border Posts (OSBPs) in East Africa have improved efficiency, navigating the customs requirements of multiple countries remains a complex task requiring specialized expertise.

This process involves more than just paying duties. It also means ensuring that all raw materials for solar panel production are correctly classified and documented to meet the import regulations of each transit country and the final destination.

Building a Resilient Supply Chain Strategy

Successfully overcoming these challenges isn’t a matter of chance—it requires a deliberate and informed strategy. Based on experience from J.v.G. Technology GmbH turnkey projects in similar regions, several elements are essential.

Partner with Regional Logistics Experts

Attempting to manage this complex supply chain without specialized local knowledge is a critical error. A reputable freight forwarder with deep experience in the chosen corridor and a proven track record in freight forwarding for Burundi is an indispensable partner.

This expert will manage customs brokerage, select reliable transport providers, and provide real-time solutions to inevitable on-the-ground challenges. The selection of this partner is as important as the selection of production machinery.

Plan for Buffers in Time and Cost

Even the best-laid plans can be disrupted by unforeseen events such as road closures, port strikes, or administrative delays. Prudent planning means building buffers into both the project timeline and the operational budget. Financial models must account for potential demurrage, storage fees, and alternative transport costs.

Qualify Your Team and Your Partners

Investors don’t need to be logistics experts themselves, but it’s vital to have a team or consultant who is. This expertise is a core competency, not an optional add-on. The qualifications required to start a solar panel factory extend beyond technical knowledge to include a firm grasp of supply chain management, particularly in challenging environments.

Frequently Asked Questions (FAQ)

How do I choose between the Dar es Salaam and Mombasa ports?

The optimal choice depends on real-time factors. Base your decision on advice from your freight forwarder, who will have current information on port congestion, road conditions, political stability, and pricing from shipping lines serving each port. A flexible strategy that allows you to use either port is ideal.

What is the biggest hidden cost in logistics for a landlocked country?

Detention and demurrage fees are consistently the most significant and often overlooked financial risks. A single delayed shipment of several containers can incur fees that erase the profit margin on the finished products.

How can I protect fragile materials like solar glass during inland transport?

Protection starts at the source with export-grade crating. For the overland journey, direct transport in the original container minimizes handling and is generally safer for fragile goods. If transloading is unavoidable, your logistics partner must use appropriate equipment and have a proven track record of handling fragile cargo.

Conclusion: Logistics as a Cornerstone of Manufacturing Success

For an entrepreneur establishing a solar module factory in a landlocked nation like Burundi, the logistics strategy is not an afterthought—it is a cornerstone of the business plan. The challenges of distance, border crossings, and container management must be addressed with the same rigor as the selection of manufacturing technology and the project’s financing.

By anticipating these hurdles and building a resilient, expert-led supply chain from day one, an investor can turn a significant risk into a manageable part of operations. This foresight is often the defining factor that separates a stalled project from a thriving manufacturing enterprise.

A comprehensive feasibility study must include a detailed and realistic analysis of this critical supply chain. To ensure your analysis is robust, explore the frameworks on pvknowhow.com.