Across Burundi, it’s a common sight: solar panels, installed just a year or two ago, are already failing. They delaminate, their output dwindles, and the initial promise of reliable electricity fades.

This situation—the direct result of a market flooded with low-quality imports—presents both a challenge and a significant business opportunity. For a new solar module manufacturer in Burundi, the path to success lies not just in production, but in establishing credibility through world-class quality control and international certification.

This article outlines a strategic pathway for a Burundian solar manufacturer to achieve globally recognized certifications, such as those from the International Electrotechnical Commission (IEC). It serves as a guide to building a reputation for quality that can serve the local market while opening doors for export across the East African Community (EAC).

Table of Contents

The Strategic Importance of Quality in Burundi’s Solar Market

Burundi boasts significant solar potential, with an average solar irradiation of 4-5 kWh/m²/day. Yet, over 90% of the population lacks access to electricity, and the national grid is often unreliable. In response, the government’s “National Development Plan of Burundi (PND 2018-2027)” prioritizes renewable energy, aiming for universal access by 2027, largely through off-grid solar solutions.

This creates immense demand for solar home systems, mini-grids for health clinics and schools, and agricultural applications. However, the market is currently saturated with low-grade imported modules that erode consumer trust.

A local manufacturer that can produce reliable, high-performance modules stands to gain a powerful competitive advantage. By achieving international certification, a Burundian company can:

- Build trust with local consumers, NGOs, and government agencies.

- Justify a premium price point over non-certified, unreliable alternatives.

- Access regional export markets within the EAC, where similar quality challenges exist.

- Become a preferred supplier for institutional and internationally funded projects that mandate certified components.

Understanding International Solar Module Standards

To earn global trust, a manufacturer must meet global standards. In the solar industry, the primary benchmarks are set by the IEC, but a solid foundation also demands a comprehensive management system.

Key Certifications for Solar Modules

IEC 61215 (Design Qualification and Type Approval): This standard tests the performance and durability of a solar module’s design. It subjects modules to a range of stressors—including temperature fluctuations (thermal cycling), humidity (damp heat), UV radiation, and physical stress (mechanical load tests)—to ensure they can withstand long-term outdoor operation.

IEC 61730 (PV Module Safety Qualification): Focused on safety, this standard ensures the module is constructed to prevent electrical shock, fire hazards, and personal injury over its lifetime. It is a prerequisite for selling modules in most regulated markets.

ISO 9001 (Quality Management System): While not a product certification, ISO 9001 is a crucial framework for running a factory. It ensures that processes for design, procurement, production, and inspection are documented, consistent, and geared toward continuous improvement. Establishing a robust Quality Management System is the first step toward producing certifiable modules.

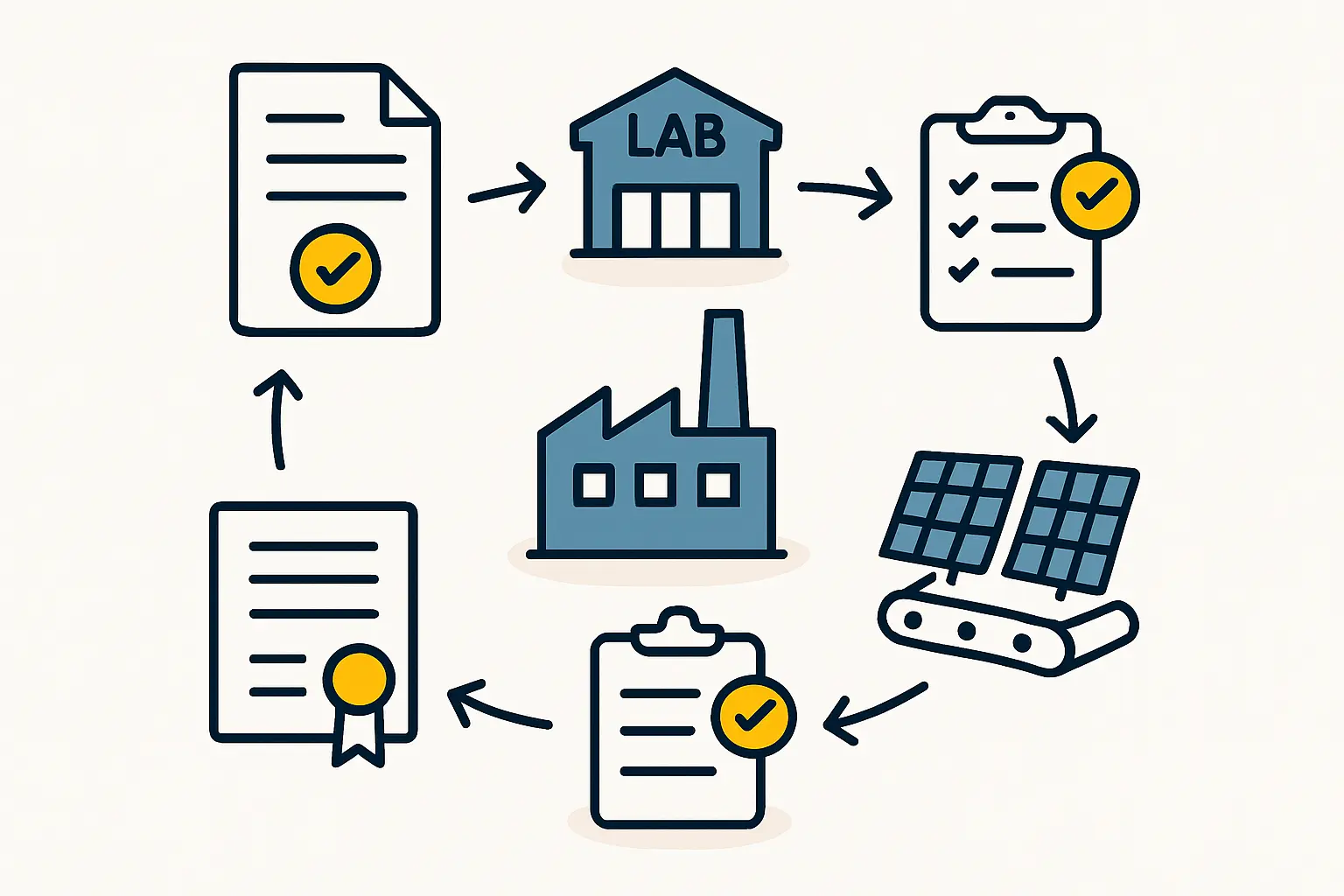

The Pathway to IEC Certification: A Step-by-Step Guide

Achieving IEC certification is a systematic process that can transform a production facility into a world-class operation. It requires meticulous planning and execution, starting long before the first module is sent for testing.

Step 1: Foundational Setup and QMS Implementation

Before producing a single module for certification, the factory must operate under a documented Quality Management System (QMS), such as ISO 9001. This involves defining all procedures, from inspecting raw materials upon arrival to the final visual check before packaging.

Step 2: Design, Bill of Materials (BOM), and Equipment

The module must be designed to meet IEC standards from the outset. This includes selecting certified raw materials (e.g., backsheet, EVA, junction box) from an approved supplier list. The solar module manufacturing equipment must also be calibrated and operated to ensure consistent, precise production.

Step 3: Production of Sample Modules

Once the production line is stable and running according to the QMS, a set of sample modules is produced. This production run must be carefully documented and monitored to demonstrate it is representative of future mass production.

Step 4: Third-Party Laboratory Testing

The sample modules are sent to an accredited, independent testing laboratory, such as TÜV Rheinland, VDE, or Intertek. There, they undergo the rigorous testing sequences defined by IEC 61215 and IEC 61730. This phase can take several months as the modules are exposed to simulated long-term environmental stress.

Step 5: The Factory Audit

Passing the lab tests is only half the battle. The certification body will send auditors to conduct an on-site inspection of the manufacturing facility in Burundi. They will verify that the factory’s QMS is being followed, the equipment is properly maintained, and the company can consistently produce modules identical to the tested samples.

Step 6: Certification and Ongoing Surveillance

Upon successful completion of lab tests and the factory audit, certification is granted. However, this is not a one-time event. The certification body will conduct regular surveillance audits (typically annually) to ensure quality standards are maintained.

Business Implications: Costs, Timelines, and Market Access

Pursuing certification is a strategic investment.

- Cost: The process for a single module series can range from €20,000 to €50,000, covering lab fees, audit expenses, and associated costs.

- Timeline: From sending samples to receiving final certification, the process typically takes four to six months.

- Return on Investment: Certification unlocks access to the entire East African Community (EAC), including promising markets like Kenya, Tanzania, and Rwanda. A “Made in Burundi” IEC-certified module becomes a premium product trusted by distributors, installers, and end-users, immediately differentiating it from low-cost, unverified imports.

Common Pitfalls to Avoid in the Certification Process

Based on experience from J.v.G. turnkey projects, new manufacturers often face several preventable challenges:

- Underestimating the QMS: A common mistake is to view the Quality Management System as mere paperwork. In reality, it is the operational backbone of a certifiable factory.

- Inconsistent Raw Materials: Using materials from non-certified suppliers or frequently changing the Bill of Materials (BOM) can invalidate test results and lead to failure during the factory audit.

- Poor Process Control: Lack of discipline on the production floor can result in variations between the certified samples and mass-produced modules, putting the certification at risk.

Frequently Asked Questions (FAQ)

What is the difference between IEC and ISO 9001?

ISO 9001 certifies a factory’s management processes, ensuring consistency and quality control in its operations. IEC 61215 and 61730 certify the final product, confirming its performance, durability, and safety based on standardized tests. A factory typically needs a strong ISO 9001 system to produce IEC-certified modules consistently.

Can a small factory in Burundi really achieve TÜV certification?

Absolutely. Certification is not about the size of the factory but the quality of its processes and product design. A well-organized small- or medium-scale facility with a robust QMS and the right equipment is fully capable of passing audits from leading bodies like TÜV Rheinland.

Do I need a separate certification for each country in the EAC?

No. IEC standards are internationally recognized. An IEC certificate issued by an accredited body like TÜV is generally accepted across the EAC and in most markets worldwide, streamlining the export process significantly.

How does certification impact the final cost of a solar module?

The certification process itself is an investment, but the primary impact on module cost comes from using high-quality, certified raw materials and maintaining strict production controls. Although this leads to a slightly higher production cost, it is easily justified by the module’s enhanced reliability, longer lifespan, and the market access that certification provides.

Preparing for a Successful Venture

For an entrepreneur entering the solar industry in Burundi, quality certification is not an optional expense—it is a foundational business strategy. It is the most effective way to build a sustainable brand, earn customer trust, and capture a leading position in a rapidly growing market.

The journey begins not on the factory floor, but with a comprehensive strategy. Developing a detailed business plan for your solar venture that integrates the costs, timelines, and requirements for certification from day one is the first critical step toward building a successful and reputable solar manufacturing enterprise in the heart of Africa.