Launching a state-of-the-art manufacturing facility in a region with immense growth potential is a complex undertaking. For entrepreneurs considering solar module production in Burundi, the opportunity is significant, but success hinges on overcoming a critical operational challenge from the outset: an unstable national power grid.

In this environment, planning for energy resilience isn’t just an advantage—it’s a fundamental requirement for building a viable and profitable enterprise.

This article outlines Burundi’s power infrastructure challenges and presents a robust technical solution for ensuring the uninterrupted, high-quality operation of a solar panel factory. It’s designed for business professionals exploring this industry who need a clear understanding of the local operational landscape.

Table of Contents

The Operational Reality of Burundi’s Power Infrastructure

A sound business plan starts with understanding the local environment. Located in the heart of East Africa’s Great Rift Valley, Burundi faces significant challenges in its national electricity sector. According to World Bank data, only about 12% of the population has access to electricity, and the national utility, REGIDESO, contends with both financial and operational hurdles.

For a prospective factory owner, these national statistics translate into direct business risks:

-

Insufficient Supply: The country’s installed capacity is approximately 96 MW, sourced primarily from hydropower (80%), which is vulnerable to climate-related issues like droughts, creating a fragile supply-demand balance.

-

Frequent Outages: Businesses in Burundi experience an average of 10 hours of power outages per month. This amounts to more than a full day of lost production time, resulting in significant revenue loss and logistical complications.

-

Poor Power Quality: Beyond simple outages, the grid often suffers from voltage fluctuations and frequency instability. These events can damage sensitive production machinery and compromise product quality.

These factors make relying solely on the national grid a high-risk strategy for an industrial operation. The planning phase for a solar module factory must, therefore, incorporate a strategy for energy independence.

Why Stable Power is Non-Negotiable for Solar Module Manufacturing

A solar panel factory is not a typical assembly plant. Its processes are precise, automated, and highly sensitive to power disruptions. A sudden loss of power or a voltage drop mid-cycle can trigger a cascade of costly problems.

The Impact on Sensitive Production Machinery

Key equipment in a solar module production line requires a consistent and clean power supply:

-

Cell Stringers: These automated machines solder solar cells together into strings with extreme precision. An interruption can cause misalignments, while a voltage sag can lead to poor-quality solder joints, creating potential failure points in the final product. This vulnerability is why a thorough understanding of every solar panel manufacturing machine is critical.

- Laminators: The lamination process involves bonding the layers of a solar module together under specific heat and pressure profiles over a set period. A power outage during this cycle can ruin the entire batch of modules inside, leading to significant material waste and financial loss.

-

Testing Equipment (Sun Simulators): These devices measure the performance of finished modules under standardized lighting conditions. Inconsistent power can skew calibration and lead to inaccurate quality control readings, potentially damaging the factory’s reputation.

For these reasons, a robust power solution is a core component of the factory’s design, not an optional extra.

The Solution: A Hybrid Power Microgrid for the Factory

The most effective way to mitigate Burundi’s grid instability is to design the factory with its own independent power system, often called a microgrid. This approach leverages the country’s greatest natural resource—abundant sunshine—to power the production of solar panels itself.

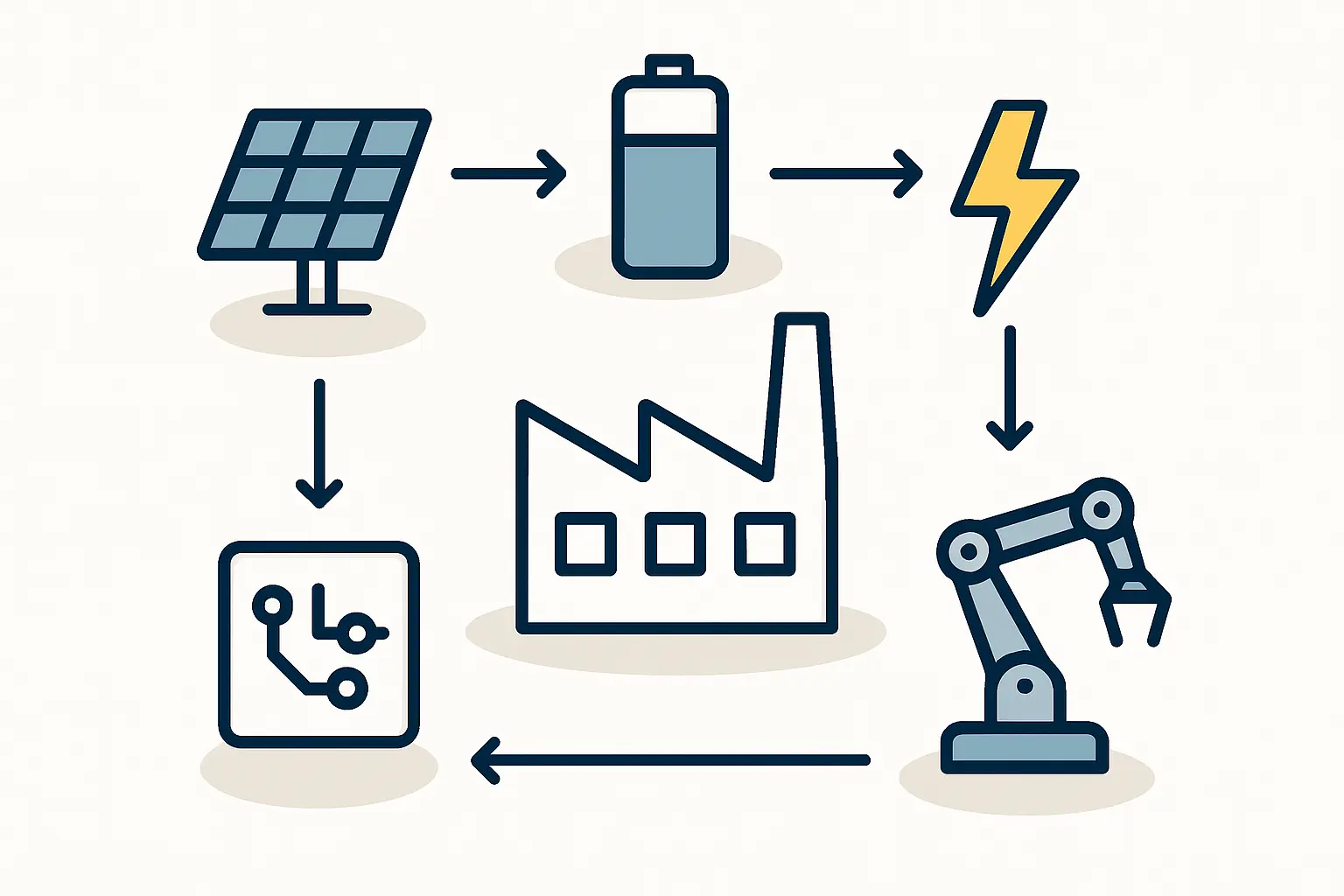

A typical hybrid power system for a solar factory includes four key components working in concert:

-

On-Site Solar PV Array: A large-scale solar installation, usually on the factory’s extensive roof space, serves as the primary power source during daylight hours. This directly converts the high solar irradiation available in Burundi into cost-effective, clean electricity.

-

Battery Energy Storage System (BESS): This is the core of the resilience strategy. A BESS stores excess energy generated by the solar array during the day. This stored energy can then power the factory at night, on overcast days, or, most critically, during a grid outage, ensuring seamless 24/7 operation.

-

Grid Connection: The factory remains connected to the national grid. This connection serves as a backup power source and, depending on local regulations, may offer the potential to sell surplus electricity back to the utility in the future.

-

Backup Generator: A diesel or gas generator provides a final layer of redundancy. It is used only during prolonged grid outages that coincide with periods of low solar generation, ensuring that production never has to stop.

This integrated system provides multiple layers of protection against power disruptions. Experience from J.v.G. Technology GmbH projects in similar regions shows that planning for energy independence from the outset is far more cost-effective than retrofitting a solution later. Integrating these systems requires a holistic approach, which is why a turnkey production line setup that considers local infrastructure from day one is often the most effective strategy.

Frequently Asked Questions (FAQ)

Q1: What is the typical size of a solar and storage system for a 50 MWp/year solar factory?

A: While specific needs vary, a factory of this size typically requires a solar PV system of approximately 500 kWp to 1 MWp and a battery storage system with a capacity of 1 MWh to 2 MWh to ensure smooth operation through evenings and shorter grid outages. A detailed energy audit during the planning phase is essential.

Q2: Is it possible to operate a solar factory completely off-grid in Burundi?

A: Yes, operating completely off-grid in Burundi is technically feasible by oversizing the solar array and battery system and including reliable backup generators. However, maintaining a grid connection where available is recommended for an additional layer of redundancy.

Q3: How does a hybrid power system impact the initial investment?

A: Although a hybrid power system increases the initial capital expenditure, this investment should be analyzed as part of the total cost of ownership. It generates significant long-term returns by eliminating downtime costs, reducing electricity bills, and protecting expensive machinery from damage.

Q4: What kind of maintenance do these power systems require?

A: Maintenance is generally straightforward. Solar panels require periodic cleaning. The battery system and inverters require regular inspections and software updates, typically handled by a qualified technical team or a service agreement. Backup generators require standard fuel and engine maintenance.

Q5: Can a factory sell excess solar power back to the grid in Burundi?

A: The regulatory framework for selling power back to the grid (net metering or power purchase agreements) is still developing in many emerging markets, including Burundi. While this may become a future revenue opportunity, the primary business case for the on-site power system should be built on operational resilience and energy cost savings.

Next Steps Toward a Successful Venture

The power infrastructure in Burundi presents a clear, manageable challenge. By incorporating a robust on-site hybrid power system into the initial factory design, an entrepreneur can transform a significant operational risk into a strategic advantage. This approach ensures production continuity and quality while powerfully demonstrating the value of the very product being manufactured.

Understanding these foundational requirements is crucial for building a successful and sustainable solar manufacturing enterprise in a region poised for growth.