While entrepreneurs considering a new venture often focus on capital, technology, and market access, the human element—a skilled workforce—is the engine that drives any manufacturing operation. In Burundi’s unique economic landscape, the question of labor can feel like a significant hurdle.

With a youth unemployment rate exceeding 50%, the available labor pool is vast, yet specific experience in photovoltaic (PV) manufacturing is virtually non-existent. This apparent paradox presents a significant opportunity. The challenge is not a lack of potential talent but the need for a structured system to cultivate it. This article lays out a practical framework for sourcing, training, and retaining a proficient local workforce for a solar module assembly line in Burundi, transforming a perceived obstacle into a strategic business advantage.

Table of Contents

Understanding the Local Labor Landscape

Before establishing a recruitment strategy, it is crucial to understand the context of the Burundian labor market. Official statistics show that while the workforce is large and available, formal technical skills for advanced manufacturing are limited. This is a common scenario in many emerging economies.

However, several underlying factors create a favorable environment for a new manufacturing facility:

-

High Labor Availability: The substantial number of individuals seeking formal employment makes finding motivated candidates a manageable task.

-

Government Focus on Vocational Training: A growing emphasis on Technical and Vocational Education and Training (TVET) programs indicates a national willingness to build a more skilled industrial workforce. This provides a foundation of candidates with basic technical aptitudes.

-

Cost-Effective Operations: Labor costs in Burundi are competitive, which significantly improves the financial viability and profitability of a new solar module factory, especially in its initial phases.

The key insight for an investor is that they do not need to find pre-existing solar experts. Instead, the objective is to identify individuals with the right aptitude and use a robust training system to build expertise from the ground up.

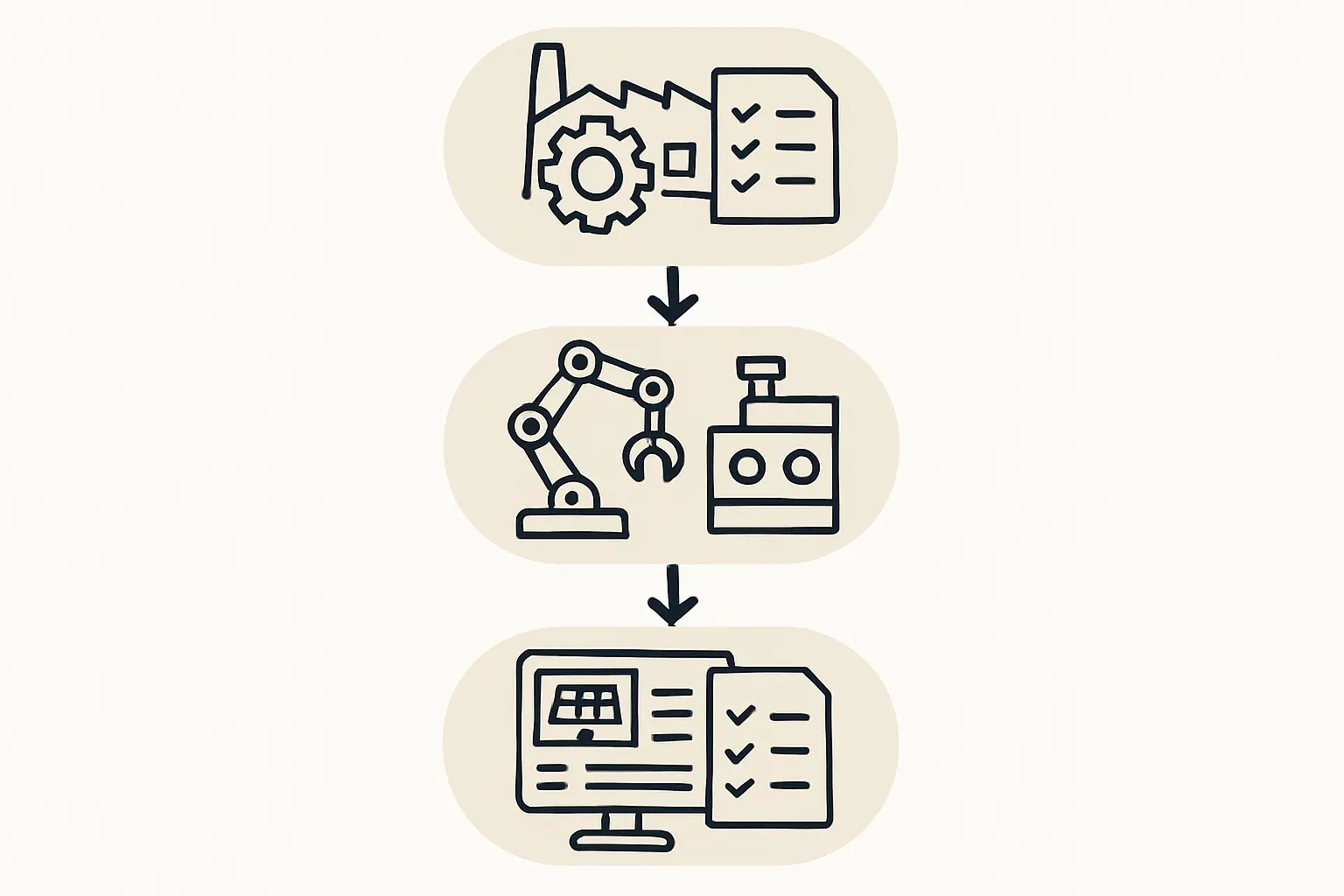

A Three-Phase Framework for Workforce Development

Drawing on experience from J.v.G. Technology GmbH turnkey projects in similar markets, a successful workforce development program can be structured in three distinct phases. This approach ensures a smooth transition from recruitment to full operational productivity.

Phase 1: Strategic Sourcing and Recruitment

The goal in this phase is not to find candidates with PV experience, but to identify individuals with the core competencies for detailed assembly work, focusing on potential rather than a pre-existing resume.

Effective Recruitment Channels:

-

Partnerships with TVET Institutions: Collaborating with local vocational schools provides access to a pre-screened pool of candidates who have already demonstrated an interest in technical fields.

-

Community Engagement: Announcing hiring opportunities through local community leaders and job boards can attract a wide range of motivated applicants.

-

Practical Assessments: During the interview process, simple hands-on tests can be more revealing than traditional interviews. A task like assembling a small component can effectively gauge an applicant’s dexterity and focus.

Building a team for a 20–50 MW semi-automated production line typically requires 25 to 30 employees, including operators, quality control staff, and a supervisor.

Phase 2: Comprehensive On-the-Job Training

This is the most critical phase, where raw potential is forged into specific skills. A well-designed training program, often led by an experienced expatriate engineer or supervisor for the initial months, is fundamental to success. This training is most effective when structured in modules.

Module 1: Foundation and Safety (1 Week)

-

Introduction to solar energy and the basic principles of a photovoltaic module.

-

Comprehensive safety training, including handling of materials, electrical safety protocols, and emergency procedures.

-

Introduction to quality standards (e.g., IEC certifications) and their importance to the business.

Module 2: Machine-Specific Training (3–5 Weeks)

-

Operators are trained in small groups on specific workstations. For instance, one group learns the cell stringer machine, another focuses on the layup station, and a third is trained to operate the solar laminator.

-

This includes hands-on training for startup, operation, basic maintenance, and troubleshooting for each piece of equipment.

Module 3: Production Line Simulation (2–4 Weeks)

-

The entire team works together on the full assembly line, initially using non-critical materials.

-

This phase focuses on developing rhythm, communication, and an understanding of how each station impacts the next.

-

Quality control personnel are trained to inspect work at each stage, from cell stringing to final EL testing and framing.

With this structured approach, a new team can typically reach target productivity and quality levels within 8 to 12 weeks. Detailing these training and staffing requirements in your solar factory business plan is a critical early step.

Phase 3: Retention and Continuous Improvement

Once the workforce is trained, the focus shifts to retaining talent and fostering a culture of excellence. In markets with limited industrial opportunities, becoming an employer of choice is a strong competitive advantage.

-

Create Career Pathways: Identify high-performing operators and offer them advanced training to become team leads or quality control specialists. Promoting from within is a powerful motivator.

-

Implement Fair Compensation: While labor costs may be low, offering competitive wages and benefits relative to the local market reduces turnover and builds loyalty.

-

Foster a Quality-First Culture: Regularly communicate the importance of quality and recognize teams or individuals who meet and exceed production standards. A strong company culture is essential for long-term success.

The entire process, from initial planning to a fully operational facility, requires a clear roadmap. For a complete overview of the necessary milestones, explore our guide on how to start a solar panel manufacturing business.

Frequently Asked Questions (FAQ)

-

Do my employees need an engineering degree to work on the assembly line? No. For operator-level positions, a technical degree is not required. The most important qualifications are manual dexterity, a strong work ethic, and the ability to follow instructions precisely. A supervisor or production manager should have a technical or engineering background, but this individual can initially be an expatriate who trains a local successor.

-

What is a realistic timeframe for a new team to become fully productive? A well-structured on-the-job training program can typically bring a newly hired team to full operational capacity, meeting both output and quality targets, within two to three months of the factory’s commissioning.

-

How many people are needed to operate a small-scale solar factory? For a semi-automated line with an annual capacity of 20 MW to 50 MW, a workforce of approximately 25 to 30 individuals is standard. This includes production line operators, material handlers, quality control inspectors, and one or two supervisors per shift. The specific labor required for a solar factory can be detailed further in the planning stage.

-

Is it possible to source supervisors and managers locally in Burundi? Initially, it may be necessary to hire an experienced expatriate production manager to establish operational standards and lead the initial training. However, a key objective should be to identify a talented local employee within the first year of operation and train them to take over this role. This approach ensures long-term sustainability and local skills transfer.

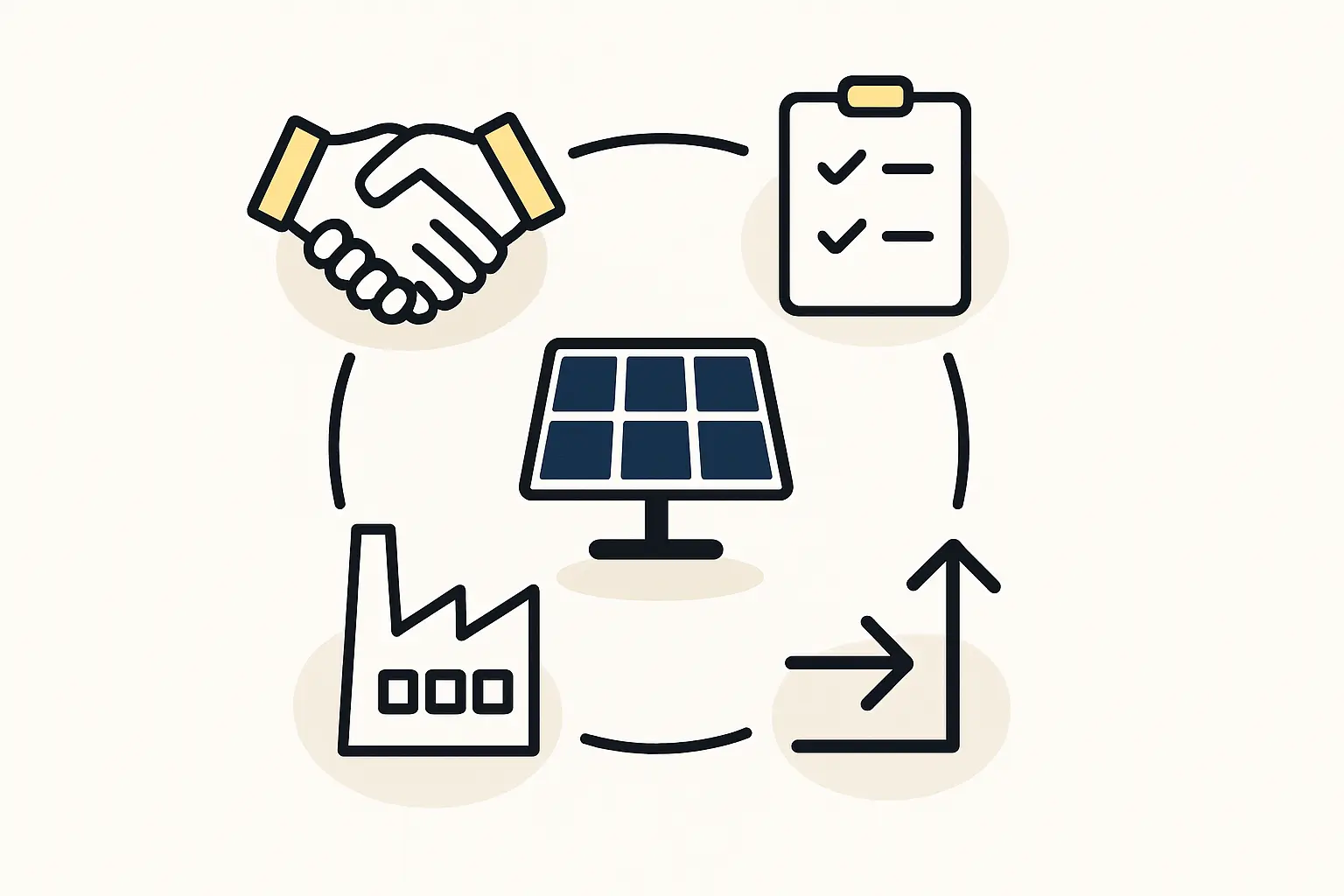

Conclusion: Building a Sustainable Asset

Establishing a solar module assembly plant in Burundi offers a compelling business case, not despite the local labor market, but because of it. The availability of a large, motivated, and cost-effective workforce is a foundational strength. Using a systematic framework for recruitment, training, and retention, an entrepreneur can build a highly skilled and loyal team from the ground up.

This process transforms unskilled labor into a precision-driven manufacturing workforce, creating a sustainable competitive advantage while contributing directly to local economic development. The key is not to search for non-existent skills but to commit to building them through a proven, structured process.