For investors considering a new manufacturing venture in an emerging market, one question consistently comes first: what about the local workforce? Is there a pool of skilled labor?

This question is especially critical for entrepreneurs exploring solar module assembly in Cabo Verde, where a common assumption is that a lack of experienced solar technicians presents a major barrier. A deeper analysis, however, reveals a different picture. The challenge is not an absence of capable individuals but a gap between general education and the specific, process-driven skills required for modern manufacturing.

This gap, when properly addressed, becomes less an obstacle and more a strategic opportunity to build a highly effective and dedicated local team from the ground up.

Table of Contents

This article provides a realistic assessment of the technical labor pool in Cabo Verde, outlining a framework for a training program designed to transform local potential into a manufacturing asset.

Understanding the Cabo Verdean Labor Landscape: A Factual Overview

An effective workforce strategy starts with reliable data. A 2021 World Bank Group report on technical and vocational training in Cabo Verde offers valuable insights for investors. Although focused on other sectors, its findings are highly relevant to a new industrial enterprise like solar module manufacturing.

Key Strengths of the Local Workforce

The data reveals a strong educational foundation. Cabo Verde boasts a high literacy rate of 86.8% and a gross secondary education enrollment rate of 85%, indicating a population that is well-educated and, most importantly, trainable. A workforce accustomed to formal learning can adapt more easily to the structured training required for quality-controlled manufacturing processes.

The Core Challenge: The “Skills Mismatch”

The World Bank report identifies a “significant mismatch between the skills supplied by the public TVET system and those demanded by the private sector.” It also notes concerns about the “quality and labor market relevance” of existing programs.

For an entrepreneur starting a solar panel business, this means expecting to hire technicians already trained in solar module assembly is unrealistic. The public training infrastructure simply isn’t designed to produce specialists for an industry new to the country.

Moreover, employers report that graduates often lack essential soft skills like problem-solving, teamwork, and professional communication.

The Strategic Opportunity

This “skills mismatch” represents not a weakness but a clean slate. Instead of retraining workers with pre-existing habits from other industries, a new factory can instill its own culture of quality, safety, and efficiency from day one. The government’s focus on skills development as a national priority also creates a supportive environment for private-sector training initiatives.

The Specific Skills Required for a Solar Panel Assembly Line

A common misconception is that a solar module factory requires a large team of highly advanced engineers. In reality, most roles on a modern solar panel assembly line are process-oriented operator positions.

The most critical competencies are rooted not in advanced technical knowledge, but in discipline and mindset:

- Attention to Detail: Ensuring cells are handled correctly, materials are aligned precisely, and visual inspections are thorough.

- Process Discipline: Following standardized operating procedures consistently to ensure uniform product quality.

- Quality Awareness: Understanding how a small deviation at one station can impact the final product’s performance and longevity.

- Basic Technical Aptitude: Operating automated machinery comfortably after receiving specific training.

- Teamwork: Communicating effectively with operators at adjacent stations to ensure a smooth production flow.

A purpose-built training program must cultivate precisely these skills.

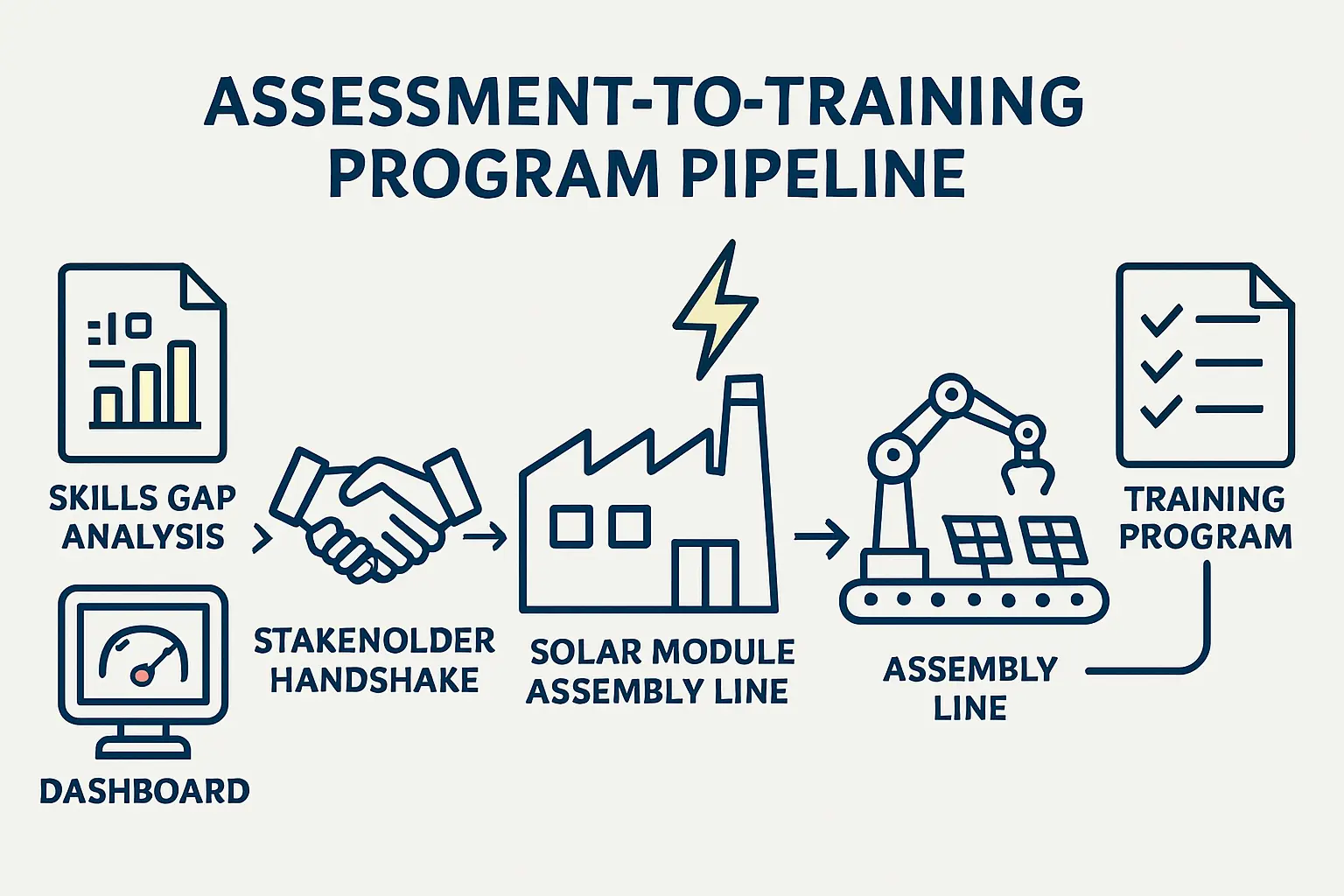

A Framework for a Custom Solar Assembly Training Program

The most effective way to close the skills gap is to implement a structured, in-house training program before the factory begins commercial operation. Experience from J.v.G. turnkey projects shows that such a program is a core component of a successful launch, transforming a group of new hires into a coordinated production team.

A comprehensive program unfolds in four distinct phases.

Phase 1: Foundation and Safety (Week 1–2)

This initial phase focuses on mindset and environment, not machinery. The goal is to ensure every employee understands the fundamentals of working in a modern factory.

Topics: Workplace safety protocols, cleanroom procedures (handling materials without contamination), an introduction to photovoltaic principles, and the fundamentals of a quality management system.

Phase 2: Machine-Specific Operation (Week 3–5)

Here, trainees work in small groups, receiving hands-on instruction at specific workstations.

Focus: Hands-on training for the primary machines: the stringer (connecting solar cells), the layup station (assembling the panel’s layers), the laminator (fusing the layers), and the final testers (IV-sun simulator and EL tester).

Phase 3: Integrated Line Simulation (Week 6–7)

In this phase, trainees operate the entire line together as a single team.

Objective: To practice the complete workflow, from raw materials to a finished panel. This stage focuses on developing communication, identifying bottlenecks, and performing basic troubleshooting under the guidance of experienced instructors.

Phase 4: Mentorship and Specialization (Week 8+)

This final phase begins as production ramps up.

New operators are paired with the initial team of experienced technicians who oversaw their training. This mentorship solidifies best practices. During this period, individuals showing an aptitude for leadership, quality control, or machine maintenance can be identified for further development.

The Role of Expatriate Expertise in Training

Developing local talent relies on an initial investment of external expertise. A successful model involves bringing in a small team of one to three experienced engineers or technicians for the factory setup and commissioning period, typically 3–6 months.

Their primary role is not to operate the factory long-term but to serve as trainers and mentors. They lead the in-house training program, establish standard operating procedures, and—most importantly—train the local line supervisors and future trainers. This “train the trainer” approach is fundamental to transferring knowledge for turnkey solar manufacturing lines and ensuring the factory’s long-term operational independence.

Frequently Asked Questions (FAQ)

Q: How long does it take to train a new solar module assembly operator?

A: An operator can be trained to a level of core competency for a specific station within a 6- to 8-week intensive program. Achieving high efficiency and the ability to troubleshoot minor issues, however, typically takes an additional 3 to 6 months of on-the-job experience.

Q: What educational background is ideal for recruits?

A: Completion of secondary school is an excellent foundation. A diploma from a technical or vocational school can be an advantage but is not essential. The most important attributes are a willingness to learn, attention to detail, and a disciplined work ethic.

Q: Is it expensive to set up an in-house training program?

A: The program is an integral part of the initial project investment, not an optional expense. The cost of structured training is minimal compared to the long-term costs of material waste, poor product quality, production inefficiencies, and high staff turnover that result from inadequate preparation.

Q: Can we rely on government training centers in Cabo Verde?

A: Public institutions can be a valuable source for candidates who have already demonstrated a commitment to learning. However, the company must lead the specific, hands-on training to ensure the skills taught align perfectly with its unique machinery, processes, and quality standards.

Conclusion: Building a Skilled Workforce as a Competitive Advantage

The labor landscape in Cabo Verde offers a clear path for investors in solar manufacturing. The foundation of an educated and trainable population is already in place. While a “skills mismatch” exists, it represents a predictable challenge that can be overcome with a strategic, company-led training program.

By investing in its local team, a new enterprise does more than fill positions—it builds a loyal, highly skilled workforce with a deeply ingrained culture of quality. In the long run, this human capital becomes one of the factory’s most significant and sustainable competitive advantages. This approach to workforce planning is a foundational element of any robust business plan for entering the solar manufacturing industry.