An investor establishes a state-of-the-art solar module factory, a multi-million dollar venture ready to capitalize on Southeast Asia’s growing demand for renewable energy. Production begins, and sophisticated machinery hums along the assembly line.

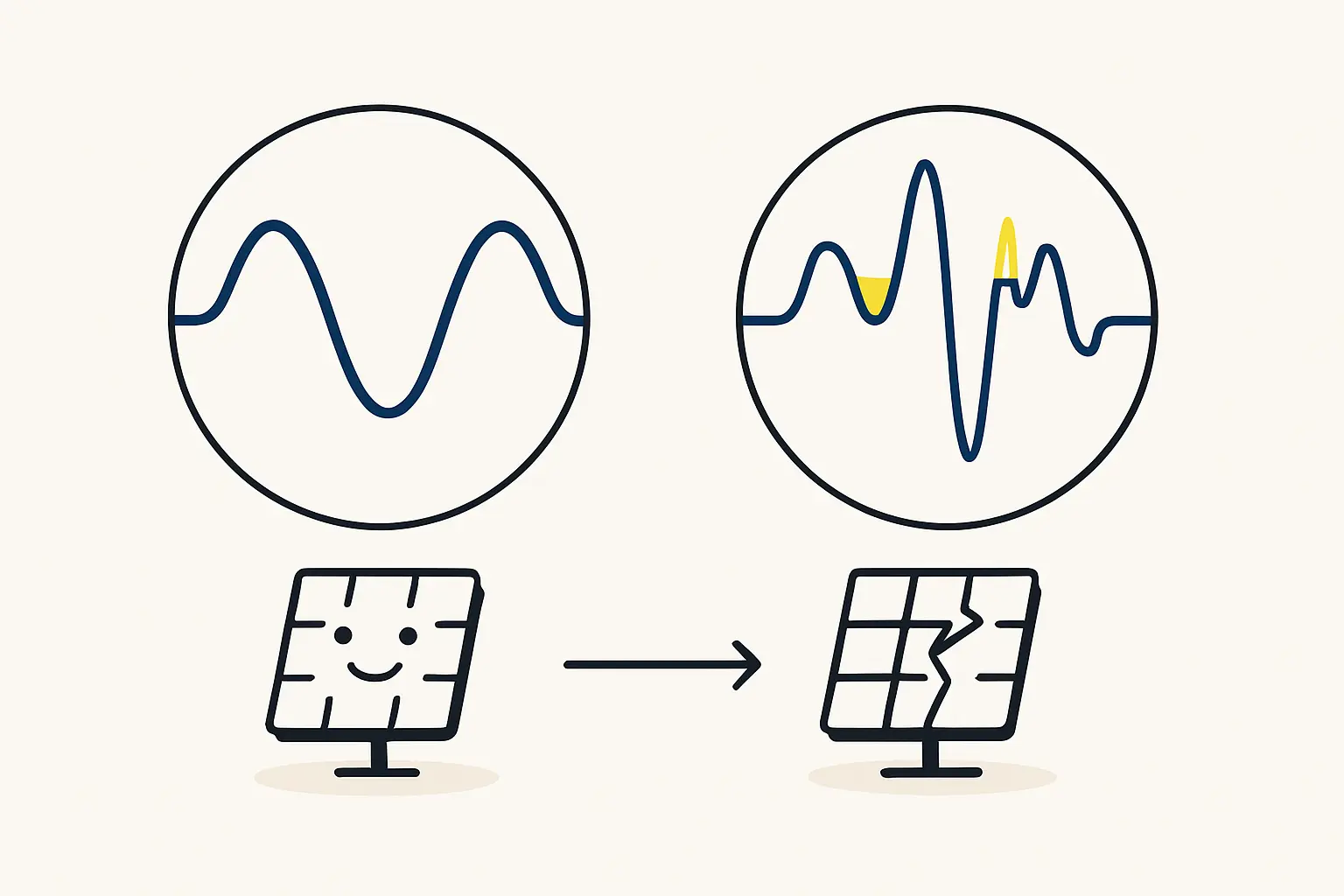

Suddenly, the lights flicker and a critical laminator—the heart of the factory—shuts down due to a brief power fluctuation.

This is more than a temporary inconvenience—it’s a costly disruption that can damage sensitive equipment, waste valuable materials, and compromise the quality of the final product.

For entrepreneurs entering Cambodia’s solar manufacturing sector, understanding the nuances of the national power grid isn’t just a minor detail; it’s a foundational pillar of a successful business plan. While the country has made significant strides in electrification, the grid’s stability remains a critical factor that directly impacts operational efficiency and profitability.

Table of Contents

Understanding Cambodia’s Power Landscape

To appreciate the challenge, it’s helpful to understand Cambodia’s energy supply structure. The nation’s power generation relies heavily on a few key sources. According to the Economic Research Institute for ASEAN and East Asia (ERIA), hydropower and coal-fired plants account for approximately 75% of the country’s domestic power generation capacity.

This reliance creates inherent vulnerabilities:

- Seasonal Variability: As a major contributor, hydropower output depends on seasonal rainfall and water levels in the Mekong River system, leading to fluctuations between the wet and dry seasons.

- Import Dependency: To meet demand, Cambodia also imports a significant amount of electricity from neighboring countries like Thailand, Laos, and Vietnam. This introduces cross-border dependencies and potential points of failure beyond domestic control.

- Infrastructure Development: While electrification has expanded rapidly, the grid infrastructure—particularly in developing industrial zones or rural areas—may not always deliver the stable, high-quality power required by sensitive industrial machinery.

These factors combine to create an environment where power outages, voltage sags, and frequency fluctuations become operational risks that must be managed proactively.

The High Cost of Unstable Power for Solar Manufacturing

In a standard manufacturing environment, a power interruption is a nuisance. In a solar module factory, it can be a catastrophic event, affecting every stage of production, from cell stringing to final testing.

Risk to Sensitive Equipment

Modern solar manufacturing relies on precision automation. Machines like automatic stringers, electroluminescence (EL) testers, and laminators are controlled by sensitive microprocessors and PLCs (Programmable Logic Controllers). An abrupt shutdown or a voltage spike can damage these electronic components, leading to expensive repairs and prolonged downtime. The laminator is often the most vulnerable piece of equipment due to its complex thermal process, where a mid-cycle power loss can be particularly damaging.

Production Losses and Material Waste

The lamination process involves heating and curing materials under a vacuum over a precise time-temperature profile. If this cycle is interrupted, the entire batch of modules inside the machine—comprising solar cells, glass, EVA film, and backsheets—is often ruined. A single failed cycle can waste materials worth hundreds or even thousands of dollars. Just a few interruptions per day can quickly escalate into significant financial losses that erode profitability.

Impact on Quality and Certification

Consistency is the cornerstone of high-quality solar module production. Unstable power can lead to subtle deviations in machine performance, such as temperature fluctuations in the laminator or inconsistent soldering in the stringer. These deviations can introduce defects that may not be immediately obvious but can lead to long-term module degradation. Such quality issues don’t just damage a brand’s reputation; they can also jeopardize the ability to achieve and maintain crucial solar module certifications, which are essential for market access.

Strategies for Ensuring Continuous Operation

Fortunately, these risks can be effectively mitigated with proper planning and investment in infrastructure resilience. The goal is to create a controlled power environment for the factory, isolated from grid fluctuations.

On-Site Backup Power Generation

The most robust solution is installing an on-site backup power source, typically a diesel generator sized to handle the factory’s full critical load. Paired with an Automatic Transfer Switch (ATS), the system detects a grid failure, automatically starts the generator, and switches the factory’s power source within seconds, allowing production to continue with minimal interruption.

Uninterruptible Power Supply (UPS) Systems

For the most sensitive electronic equipment, such as control computers and testing servers on the solar factory equipment list, a UPS system provides an additional layer of protection. A UPS is essentially a large battery that delivers instantaneous, clean power the moment the grid falters. It bridges the critical few seconds between the grid outage and the generator kicking in, ensuring these core systems experience zero downtime.

Power Conditioning and Voltage Stabilizers

In areas where the primary issue isn’t complete outages but rather voltage fluctuations (brownouts or surges), power conditioning equipment can be a valuable investment. Industrial-grade voltage stabilizers monitor incoming power and automatically adjust it, providing a consistent, stable voltage to the machinery and protecting it from the damaging effects of poor power quality.

Experience from J.v.G. turnkey projects shows that incorporating a robust power backup strategy from the initial planning phase is one of the highest-return investments an entrepreneur can make. In one analysis for a project in a region with grid characteristics similar to Cambodia’s, the projected cost of just one week of unplanned downtime from power issues far exceeded the entire investment in the generator and UPS systems. This reframes power infrastructure from a mere operational cost into a strategic asset that underpins the entire turnkey solar production line.

Frequently Asked Questions

Q: Is a backup generator always necessary for a solar factory in an emerging market?

A: While not always legally mandatory, it’s highly recommended for business continuity. The risk of production loss, material waste, and equipment damage from even a single significant power outage typically justifies the investment in a backup generator for any serious manufacturing operation.

Q: What is the typical investment for a backup power system for a 20-50 MW factory?

A: The cost can vary widely based on the total power load, the generator brand, and local installation costs. However, a business owner should budget in the range of $50,000 to $150,000 USD for a suitably sized diesel generator, Automatic Transfer Switch, and installation for a small to medium-sized factory.

Q: How does a power outage affect a solar laminator specifically?

A: If power is lost mid-cycle, the heating elements turn off and the vacuum pump stops. The materials inside cool unevenly and without proper pressure, leading to delamination, bubbles, and uncured encapsulant. The entire module laminate is typically unsalvageable and must be scrapped.

Q: Can a solar factory use its own solar panels to power itself during a grid outage?

A: This is a common question. While theoretically possible, the solution isn’t simple. Standard grid-tied solar systems are designed to shut down during a grid outage for safety reasons. To power the factory, one would need a much more complex and expensive hybrid system with large-scale battery storage and specialized inverters capable of creating an independent ‘island’ grid. For most factories, a diesel generator remains the more reliable and cost-effective primary backup solution for ensuring 24/7 production capability.

From Infrastructure Risk to Operational Resilience

Entering the solar manufacturing industry in a dynamic market like Cambodia offers immense opportunity. Success, however, depends on a clear-eyed assessment of local operating conditions.

Power grid stability is a critical variable that cannot be overlooked.

By anticipating these challenges and integrating solutions like backup generators and UPS systems into the initial factory design, an entrepreneur transforms a potential liability into a source of competitive advantage. A factory that can guarantee consistent production and quality, regardless of grid conditions, is a factory built for long-term success.