An entrepreneur invests millions to build a new solar module factory. A state-of-the-art production line is installed, the staff is trained, and the first major order is secured. Then, production grinds to a halt.

The culprit isn’t a technical failure but a supply disruption. A key component, EVA film, is delayed for weeks because of a sudden power curtailment policy enacted in a single Chinese province thousands of kilometers from the shipping port.

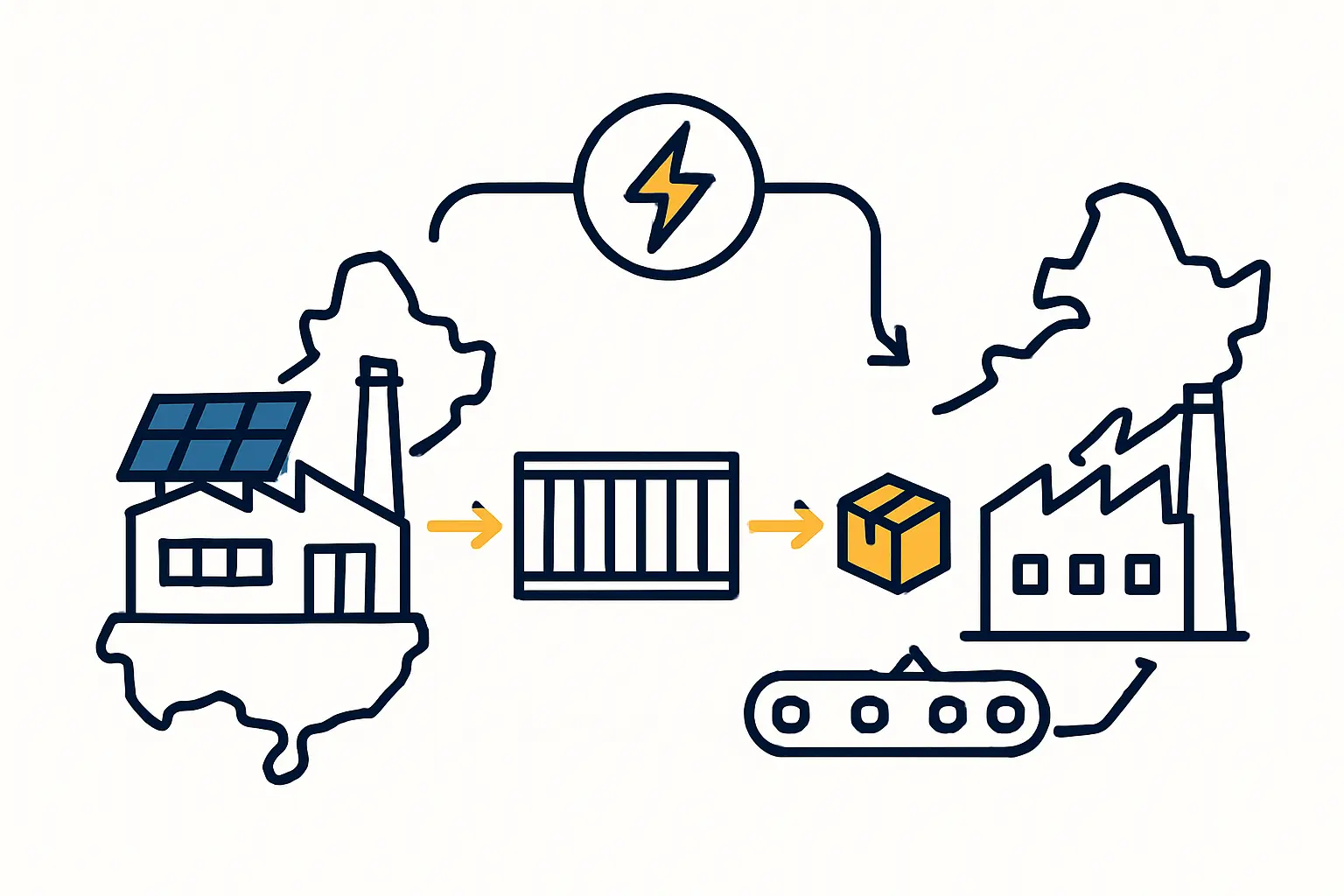

This scenario, while hypothetical, illustrates a critical vulnerability for new entrants in the solar manufacturing industry. While China offers unparalleled scale and cost-effectiveness for components, its highly concentrated production landscape also presents significant risks. Building a resilient supply chain isn’t just a logistical task—it’s a foundational business strategy.

Table of Contents

The Reality of China’s Dominance in Solar Manufacturing

To understand the need for a resilient supply chain, you first have to grasp the scale of China’s role in the global solar industry. According to the International Energy Agency (IEA), China’s share of global manufacturing capacity for solar components is immense:

- Polysilicon: Over 80%.

- Ingots and Wafers: Approximately 97%.

- Photovoltaic Cells: Around 85%.

- Solar Modules: Approximately 75%.

This dominance stems from years of strategic investment, industrial policy, and the development of vast economies of scale, leading to manufacturing costs significantly lower than in other regions. For a new factory owner, sourcing from China isn’t just an option—it’s often the most economically viable path.

However, this dependency requires a deep understanding of the associated risks and how to manage them. Before diving into strategy, a firm grasp of the core components is essential. You can find a detailed overview in our guide on understanding the key raw materials for solar panel manufacturing.

Geographic Concentration: A Double-Edged Sword

The efficiency of China’s solar supply chain is partly due to its geographic concentration. Key manufacturing activities are clustered in specific provinces. For instance, regions like Xinjiang have become central to polysilicon production, while provinces such as Jiangsu and Zhejiang are major hubs for cell and module manufacturing.

This clustering creates an efficient ecosystem where suppliers, manufacturers, and logistics providers operate in close proximity. However, it also introduces a single point of failure. A regional lockdown, an energy policy shift, a natural disaster, or logistical bottlenecks in one of these key provinces can have a ripple effect across the entire global supply chain.

This concentration means a disruption in one region can jeopardize the availability of a critical component for factories worldwide, making a proactive risk mitigation strategy essential.

Identifying and Mitigating Key Supply Chain Risks

Recognizing potential risks is the first step toward building resilience in the solar industry. The primary challenges aren’t always obvious and extend far beyond simple price negotiations.

The Risk of Single-Source Dependency

Relying on a single supplier for a critical component, even a large and reputable one, exposes a manufacturing operation to significant risk. If that supplier faces production issues, quality control problems, or financial difficulties, the factory’s entire production schedule is jeopardized. The goal is to avoid a situation where one supplier’s problem becomes your business’s crisis.

Logistical and Infrastructure Bottlenecks

The journey of a component from a factory in an inland Chinese province to a shipping port and, ultimately, to your facility is complex. Potential bottlenecks include:

- Port Congestion: Delays at major ports like Shanghai or Ningbo can hold up shipments for weeks.

- Internal Transport: Local lockdowns or restrictions on road and rail transport can prevent components from reaching the port.

- Energy Shortages: As seen in recent years, regional power rationing can force suppliers to reduce or halt production, directly impacting output.

Geopolitical and Policy Shifts

International trade relationships can be volatile. Tariffs, trade disputes, or changes in export regulations can suddenly increase costs or restrict the flow of goods. While these factors are often beyond an individual company’s control, a diversified sourcing strategy can provide a buffer against their most severe impacts.

Strategies for Building a Resilient Sourcing Framework

A resilient supply chain isn’t about finding the single cheapest supplier; it’s about creating a flexible and robust network that can adapt to disruptions. Based on experience from J.v.G. turnkey projects, the following strategies have proven effective.

Strategy 1: Provincial Diversification

Instead of sourcing a single component from one location, identify and qualify suppliers in at least two different provinces. For example, a factory could source its solar glass from a primary supplier in Jiangsu and a secondary, pre-qualified supplier in Anhui. This approach mitigates the risk of a regional disruption impacting your entire supply of that component.

Strategy 2: Qualifying Multiple Suppliers

For every critical item in your solar module bill of materials (BOM), aim to have at least one primary and one secondary supplier fully qualified. The qualification process involves not just price negotiation but also technical validation and quality audits. This ensures that if the primary supplier fails to deliver, the business can pivot to the secondary supplier with minimal disruption to production quality or timelines.

Strategy 3: Strategic Inventory Management

While lean manufacturing principles advise against excessive inventory, holding a strategic buffer of critical components can be a prudent investment. Maintaining a four- to eight-week supply of key materials like solar cells or junction boxes can allow a factory to continue operations while resolving a short-term supply chain issue. Striking the right balance requires weighing the cost of holding inventory against the potential cost of a production stoppage.

Strategy 4: Building Strong Supplier Relationships

View suppliers as long-term partners, not just transactional vendors. Regular communication, transparent forecasting, and a clear understanding of their own operational challenges can lead to preferential treatment during periods of tight supply. A strong relationship can also provide valuable early warnings of potential disruptions, allowing for proactive adjustments.

A Note on Due Diligence and Quality Control

Diversifying suppliers must never come at the expense of quality. Each new potential supplier must undergo a rigorous vetting and quality control process. This includes sample testing, factory audits, and establishing a clear incoming quality control (IQC) procedure at your own facility.

The components must meet the required standards to ensure the final product can be certified. A thorough understanding of the importance of solar panel certifications and testing is non-negotiable for ensuring the bankability and market acceptance of your solar modules.

Frequently Asked Questions (FAQ)

Q: Isn’t it cheaper to use just one large supplier for all components?

A: Initially, consolidating orders with a single large supplier may yield volume discounts. However, this approach concentrates risk. The potential financial loss from a single production shutdown lasting several weeks often far outweighs the marginal cost savings achieved through single-sourcing. Think of a resilient supply chain as a form of business insurance.

Q: How does a new entrepreneur find reliable alternative suppliers in different Chinese provinces?

A: This process requires diligent on-the-ground research, participation in industry trade shows, and often, engaging an experienced consultancy with an established network in the region. Local partners can help verify credentials, conduct factory audits, and navigate cultural and linguistic barriers.

Q: Does diversifying my supply chain within China protect my business from international trade disputes?

A: Diversifying within China primarily mitigates internal logistical, regional, and single-supplier risks. It provides limited protection against broad international tariffs or trade policies that target all goods exported from China. However, a well-managed and cost-efficient supply chain can help a business better absorb the impact of such external pressures.

Building a Foundation for Long-Term Success

Structuring a supply chain within China’s complex industrial landscape can seem daunting, especially for those new to the solar sector. Yet, it is a manageable and essential part of the strategic planning process.

By moving beyond a focus on the lowest initial price and instead prioritizing resilience, diversification, and quality, an entrepreneur can build a manufacturing operation that is prepared for uncertainty. This foresight is what separates the businesses that merely survive from those that thrive in the long term.