While Colombia is known for its rich history in traditional energy sectors, a significant opportunity is quietly emerging, powered by some of the most consistent solar irradiation in the world.

The Colombian government’s goal to generate 30% of its energy from non-conventional renewable sources by 2030 is more than a policy statement; it is a clear signal to entrepreneurs and investors. For professionals considering new ventures, this ambition raises a critical question: what is the real cost of entry into the solar manufacturing space?

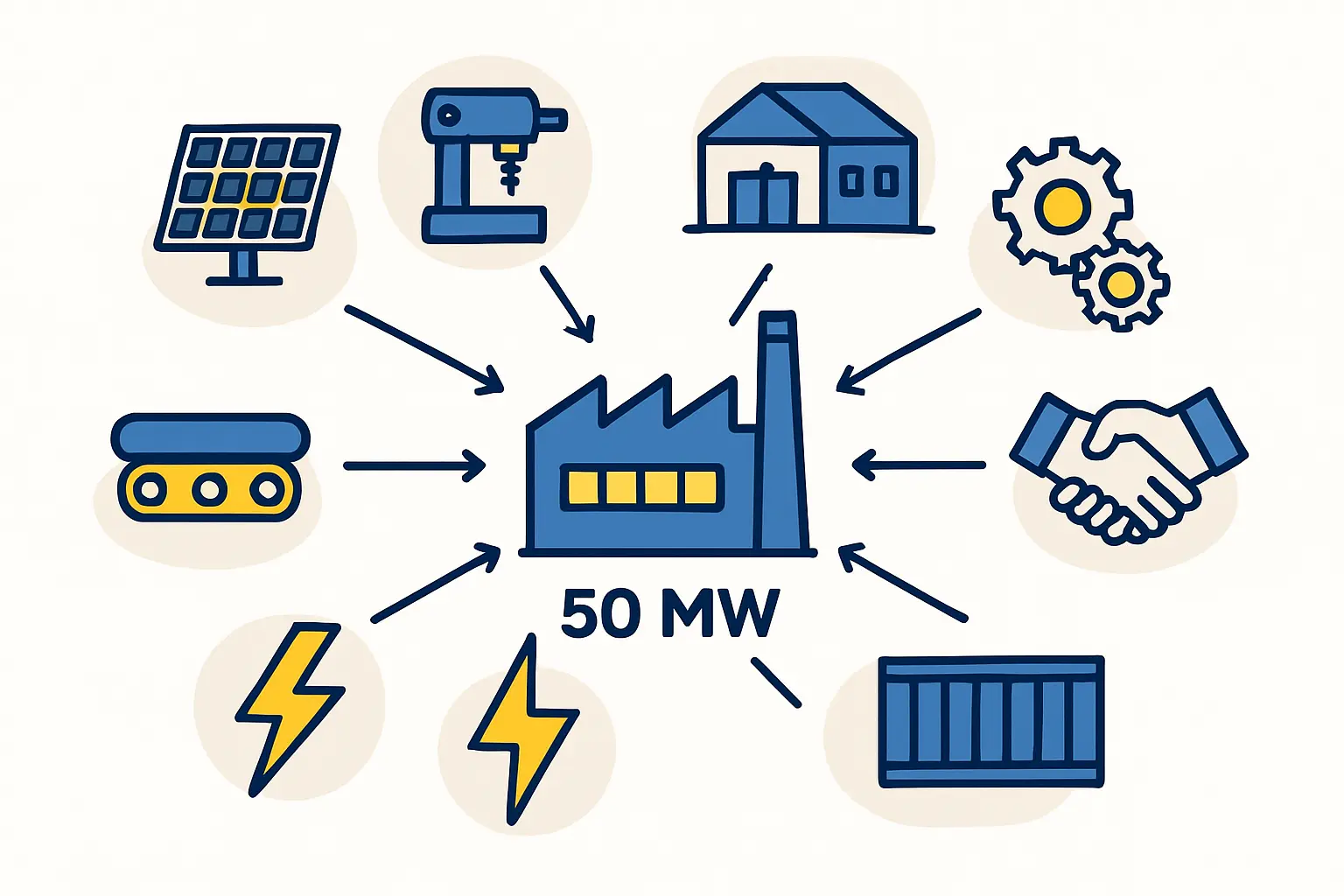

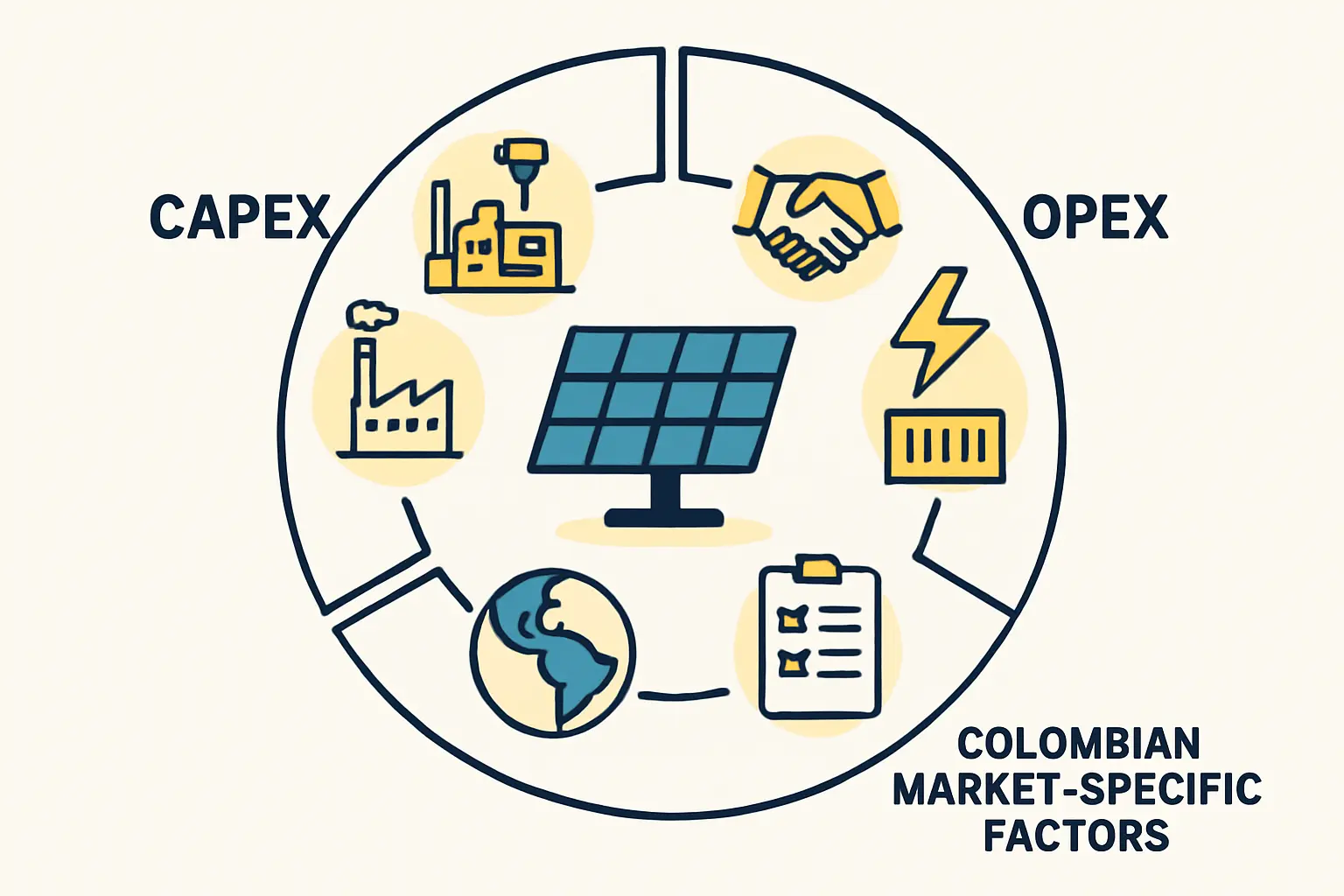

This article lays out a detailed financial model for establishing a 50 MW solar module assembly line in Colombia. We break down both the capital expenditures (CAPEX) required to build the factory and the operational expenditures (OPEX) to run it, offering a data-driven perspective essential for strategic planning.

Table of Contents

The Strategic Case for Solar Manufacturing in Colombia

Before diving into the numbers, it’s essential to understand Colombia’s unique business environment. The case for local production rests on three pillars: immense natural resources, supportive government policy, and a growing domestic market that currently relies on imports.

Colombia’s position near the equator ensures high and stable solar irradiation levels, often exceeding 4.5 kWh/m² per day. This consistent energy potential creates reliable, year-round demand for solar installations, from large-scale utility projects to off-grid rural solutions.

Furthermore, government initiatives like Law 1715 of 2014 offer significant financial incentives, including income tax deductions, accelerated depreciation, and exemptions from VAT and customs duties for renewable energy investments. This framework is designed to attract the kind of long-term capital required for manufacturing. By producing locally, an entrepreneur can serve the domestic market more efficiently while contributing to the nation’s energy independence and supply chain security.

Capital Expenditure (CAPEX): The Initial Investment

Capital expenditure is the one-time investment required to acquire and install the assets needed to begin production. For a 50 MW solar module factory, this represents the most significant initial financial outlay.

Production Machinery: The Core of the Factory

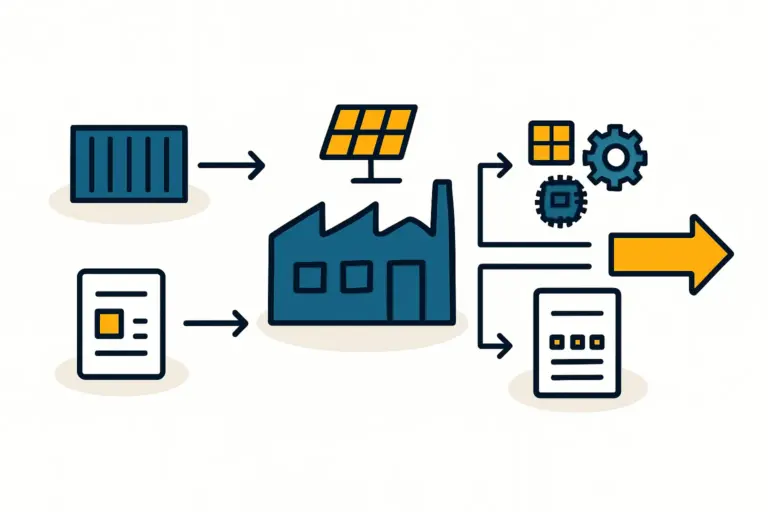

The heart of any solar module factory is its assembly line. A semi-automated 50 MW line relies on several key machines, working in sequence, to transform raw materials into a finished solar panel.

Key equipment includes:

- Cell Stringer: Connects individual solar cells into strings.

- Layup Station: Assembles the layers of the module (glass, EVA, cell strings, backsheet).

- Laminator: Uses heat and pressure to encapsulate the components into a durable sandwich.

- Framer: Attaches the aluminum frame for structural integrity.

- Sun Simulator / IV Tester: Tests the finished module’s electrical performance against quality standards.

Based on experience from J.v.G. turnkey projects, the investment for a complete set of European-standard solar module manufacturing machines for a 50 MW line typically ranges from $1.5 million to $2.5 million USD. This range accounts for variations in the level of automation and the equipment manufacturer.

Building and Infrastructure

The factory itself must meet specific requirements. A 50 MW line typically needs a factory floor of approximately 2,500 to 3,500 square meters. This space must accommodate the production line, raw material storage, finished goods warehousing, and administrative offices.

Key infrastructure considerations include:

- Reinforced Flooring: To support the weight of heavy machinery like the laminator.

- Climate Control: An air-conditioned, dust-free environment is crucial for quality control during the layup and lamination stages.

- Utility Connections: A stable and sufficient supply of electricity, compressed air, and water is non-negotiable.

Building preparation costs can vary significantly, depending on whether an existing facility is being retrofitted or a new one is constructed. A detailed solar panel factory layout is essential for optimizing workflow and minimizing these costs.

Ancillary Costs: Beyond the Machines

Several other one-time costs are critical for a successful launch:

- Shipping, Insurance, and Customs: Transporting machinery from Europe or Asia to a Colombian port (e.g., Cartagena, Buenaventura) and then inland.

- Installation and Commissioning: On-site setup and calibration of the production line by expert engineers.

- Staff Training: Ensuring the local workforce is fully trained on machine operation and quality control protocols.

- Initial Raw Material Stock: A two- to three-month supply of materials is needed to start production smoothly.

- Certifications: A budget for obtaining necessary product certifications, such as IEC 61215 and IEC 61730, which are vital for market access.

Operational Expenditure (OPEX): The Ongoing Costs

Once the factory is operational, its long-term profitability hinges on managing ongoing costs (OPEX)—the recurring expenses of running the day-to-day business.

Direct Labor Costs

A semi-automated 50 MW line operating on a single shift requires a team of roughly 30 to 40 employees, including machine operators, quality control inspectors, maintenance technicians, and warehouse staff. Colombia’s competitive labor market can be a significant advantage. While skilled technical roles command higher salaries, the overall labor cost structure is often more favorable than in developed manufacturing economies, directly impacting the final cost per module.

Raw Materials (Bill of Materials – BOM)

Raw materials represent the single largest component of operational costs, often accounting for over 80% of a finished module’s price. Key materials include solar cells, tempered glass, EVA (Ethyl Vinyl Acetate) film, backsheet or a second layer of glass, aluminum frames, and junction boxes.

Because most of these materials must be imported, establishing a robust and cost-effective supply chain is paramount. A successful operation in Colombia requires expertise in international logistics, customs clearance, and inventory management to mitigate supply disruptions and currency fluctuations.

Utilities and Maintenance

Manufacturing solar panels is an energy-intensive process. A 50 MW factory’s electricity consumption can be substantial, particularly for the laminator and climate control systems. Given Colombia’s variable grid stability in certain regions, an investment in backup power generation can be a necessary expense to ensure uninterrupted production. Regular preventive maintenance for all machinery is also a critical expense to maximize equipment lifespan and avoid costly downtime.

Financial Summary: A 50 MW Factory in Numbers

The following table provides an estimated financial overview. These figures are a guide for initial planning; a comprehensive business plan with project-specific quotations is essential.

Expenditure Category: Capital Expenditure (CAPEX)

Notes: One-time investment to establish the factory.

- Production Machinery: $1,500,000 – $2,500,000.

- Building & Infrastructure: $300,000 – $800,000+.

- Ancillary Costs: $200,000 – $400,000.

Total Estimated CAPEX: $2,000,000 – $3,700,000.

Note: Excludes working capital and initial raw material stock.

Expenditure Category: Operational Expenditure (OPEX)

Notes: Annual costs at full single-shift capacity.

- Direct Labor (35 employees): ~$250,000 – $400,000 per year.

- Raw Materials (BOM): ~$12,000,000 – $15,000,000 per year.

- Utilities & Maintenance: ~$150,000 – $250,000 per year.

Frequently Asked Questions (FAQ)

Q: How long does it take to establish a 50 MW solar factory?

A: From the final decision and placement of machinery orders, a typical project timeline is 9 to 12 months. This includes machine manufacturing (4-6 months), shipping (2 months), and on-site installation, commissioning, and training (2-3 months).

Q: Are there specific certifications required to sell solar panels in Colombia?

A: Yes. Products must comply with the Colombian technical regulation for electrical installations (RETIE). Additionally, international certifications like IEC 61215 (performance) and IEC 61730 (safety) are standard requirements to ensure bankability and access to larger commercial and utility-scale projects.

Q: Can an entrepreneur without a technical background succeed in this industry?

A: Absolutely. Many successful factory owners come from business, finance, or other industrial backgrounds. Success depends not on being a photovoltaic expert, but on partnering with experienced technical consultants and hiring a strong local management team. The key is a structured, well-planned approach.

Q: What are the biggest logistical challenges in Colombia?

A: The primary challenges revolve around managing the import supply chain. This includes navigating customs procedures, managing import duties (though incentives may apply), and ensuring efficient inland transportation from major ports to the factory location. Building strong relationships with logistics partners is essential.

Planning Your Next Steps

Establishing a solar module factory in Colombia is a significant undertaking, but one with a compelling strategic rationale. The combination of abundant solar resources, government support, and a growing market creates a strong foundation for a profitable venture.

However, success requires more than capital—it demands meticulous planning, technical understanding, and strategic execution. For entrepreneurs ready to explore this opportunity, the next step is to gain a clear understanding of the entire process from concept to operation.

Learning more about the turnkey solar manufacturing line process offers a comprehensive roadmap for this journey. To get started, the free educational courses on pvknowhow.com will guide you through each stage of this complex yet rewarding process.