Imagine a new solar module factory on the outskirts of Bogotá. The production line is state-of-the-art, the staff is trained, and the first batch of high-quality photovoltaic modules is ready for the market. But every shipment is halted at the gate.

The reason? A missing document: the RETIE Certificate of Conformity. This scenario isn’t hypothetical—it’s a critical reality for any entrepreneur entering Colombia’s solar manufacturing sector.

For those planning to manufacture and sell solar modules in Colombia, understanding the Reglamento Técnico de Instalaciones Eléctricas (RETIE) is non-negotiable. This mandatory regulation ensures every electrical product, including solar panels, is safe and reliable under the country’s unique conditions. This guide provides a clear overview of the RETIE standard, its technical requirements, and the compliance process, transforming a potential obstacle into a structured part of your business plan.

Table of Contents

Understanding RETIE: More Than Just a Quality Seal

RETIE is the national technical regulation governing electrical installations and products in Colombia. Its primary purpose is to protect human and animal life, preserve the environment, and prevent practices that could mislead consumers. Unlike a voluntary quality standard, RETIE compliance is enforced by law. Every solar module sold or installed in the country must bear proof of this certification.

While RETIE is a national standard, it does not exist in a vacuum. It builds upon internationally recognized frameworks, primarily the standards of the International Electrotechnical Commission (IEC). An IEC certificate alone, however, is not enough. RETIE adapts these global standards to address Colombia’s unique environmental and electrical grid conditions, such as high altitudes, significant humidity, and specific grid stability challenges.

The Core Technical Requirements for Solar Modules

Achieving RETIE certification requires manufacturers to demonstrate compliance in several key areas. The process verifies not only the final product but also the components and documentation that support it.

Performance and Safety Standards

The foundation of RETIE compliance for solar modules rests on two core international standards:

- IEC 61215: This standard covers design qualification and type approval for crystalline silicon terrestrial photovoltaic modules, testing their long-term performance under various stress conditions.

- IEC 61730: This standard specifies safety requirements for PV modules, ensuring they can operate safely over their entire lifespan.

Manufacturers must ensure their modules pass all tests associated with these IEC 61215 and IEC 61730 certifications. A RETIE-accredited body will verify these test reports or conduct its own tests to confirm that the modules can withstand the mechanical loads, extreme temperatures, and electrical stresses typical of Colombian environments.

Product Labeling and Documentation

Clear and accurate information is a cornerstone of RETIE. All labels, datasheets, and installation manuals must be in Spanish—a common oversight for international ventures that can cause significant delays.

The module’s permanent label, affixed to its back, must contain specific information, including:

- Manufacturer’s name and country of origin.

- Model and serial numbers.

- Key electrical characteristics (Pmax, Vmp, Imp, Voc, Isc) under Standard Test Conditions.

- Maximum system voltage.

- The official RETIE certification mark and certificate number.

Component-Level Compliance

A solar module is only as reliable as its parts, so the RETIE certification process scrutinizes the entire supply chain. A well-structured Bill of Materials (BOM) is essential, and all critical components within it must meet their own quality and safety standards.

Key components under review include:

- Junction Boxes and Connectors: Must be certified to prevent moisture ingress and ensure safe electrical connections.

- Backsheet and Encapsulant (EVA): Must demonstrate long-term durability and electrical insulation properties.

- Solar Glass: Must meet standards for impact resistance and transmissivity.

Sourcing pre-certified components is a critical strategy for streamlining the final module certification process.

The RETIE Certification Process: A Step-by-Step Overview

Navigating the certification process requires a methodical approach. While specifics can vary between certification bodies, the general path is consistent.

Step 1: Partner with an ONAC-Accredited Body

The first step is selecting a certification body accredited by the Organismo Nacional de Acreditación de Colombia (ONAC). ONAC accredits the laboratories and entities qualified to test and approve products according to RETIE standards. It’s wise to engage with a potential partner early to understand their specific requirements and timelines.

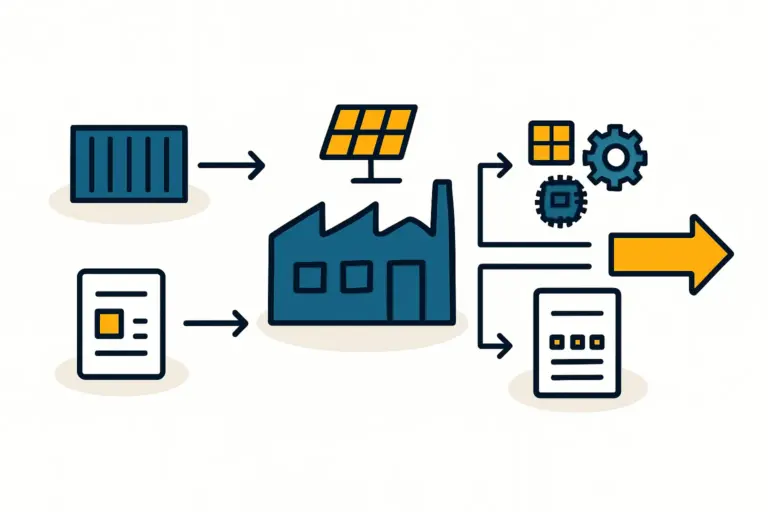

Step 2: Submit a Technical File and Test the Product

The manufacturer must compile and submit a comprehensive technical file, including detailed design drawings, the Bill of Materials, component datasheets, and existing test reports like IEC certificates. Once the documentation review is complete, sample modules from the production line are sent to an accredited laboratory for rigorous testing to verify performance and safety claims.

Step 3: Undergo a Factory Audit

The on-site factory inspection is a crucial part of the process. Auditors from the certification body will visit the manufacturing facility to assess its quality management system. They will verify that the solar module production line operates according to documented procedures, that equipment is properly calibrated, and that robust traceability systems are in place from raw materials to finished goods.

Step 4: Obtain and Maintain the Certificate

Once product testing and the factory audit are successfully completed, the certification body issues the RETIE Certificate of Conformity. The process, however, does not end here. The certificate is typically valid for three years and requires annual surveillance audits to ensure the manufacturer maintains the required quality standards. This long-term commitment must be factored into operational planning.

Common Challenges and How to Prepare for Them

Experience from J.v.G. turnkey projects in emerging markets shows that addressing certification requirements early is critical for a successful launch. New manufacturers often face similar—and preventable—challenges.

- Underestimating Timelines and Costs: The entire certification process, from initial application to final approval, can take 6 to 12 months. The costs, including testing fees, audit expenses, and annual surveillance, should be built into the initial business budget.

- Incomplete or Non-Compliant Bill of Materials (BOM): A common delay arises when a key component is found to be uncertified. Vetting suppliers and demanding compliance documentation for every item on the BOM from the outset is essential.

- The Language Barrier: The requirement for all documentation and labeling to be in Spanish is absolute. Neglecting this can lead to failed audits and rejected applications. Appointing a Spanish-speaking team member or a local consultant to manage documentation is a wise investment.

Frequently Asked Questions (FAQ) about RETIE Certification

Q: Is an existing IEC certificate enough to sell modules in Colombia?

A: No. While IEC 61215 and 61730 certificates are foundational prerequisites, they are not a substitute for the mandatory RETIE certificate. The product must be certified by an ONAC-accredited body specifically for the Colombian market.

Q: How long is a RETIE certificate valid?

A: A RETIE Certificate of Conformity is generally valid for three years, but it is subject to annual surveillance audits to maintain its validity.

Q: What are the consequences of selling non-certified solar modules?

A: Selling products without a valid RETIE certificate is illegal and can lead to severe consequences, including fines, mandatory product recalls, a ban on sales, and significant reputational damage.

Q: Can the certification process begin before the factory is fully operational?

A: Initial stages, like documentation preparation and dialogue with a certification body, can begin early. However, final product testing and the mandatory factory audit can only be completed once the production line is operational and producing consistent, high-quality modules.

Integrating RETIE into Your Business Plan

For any entrepreneur aiming to establish a solar module manufacturing presence in Colombia, RETIE should not be viewed as a bureaucratic hurdle, but rather as a framework for excellence and a key market enabler. Achieving certification demonstrates a commitment to safety and quality, building trust with customers, distributors, and government entities.

The journey to compliance requires meticulous planning and foresight. By integrating the certification timeline and costs into your initial solar factory investment plan, you position your enterprise for a smooth and successful market entry. For those developing a manufacturing strategy, understanding these regulatory landscapes is a core component of the planning process, a subject covered in detail within the pvknowhow.com e-course.