An entrepreneur preparing to launch a solar module factory envisions a state-of-the-art production line, smoothly assembling panels destined to power the nation. But the reality often begins with a far more fundamental challenge.

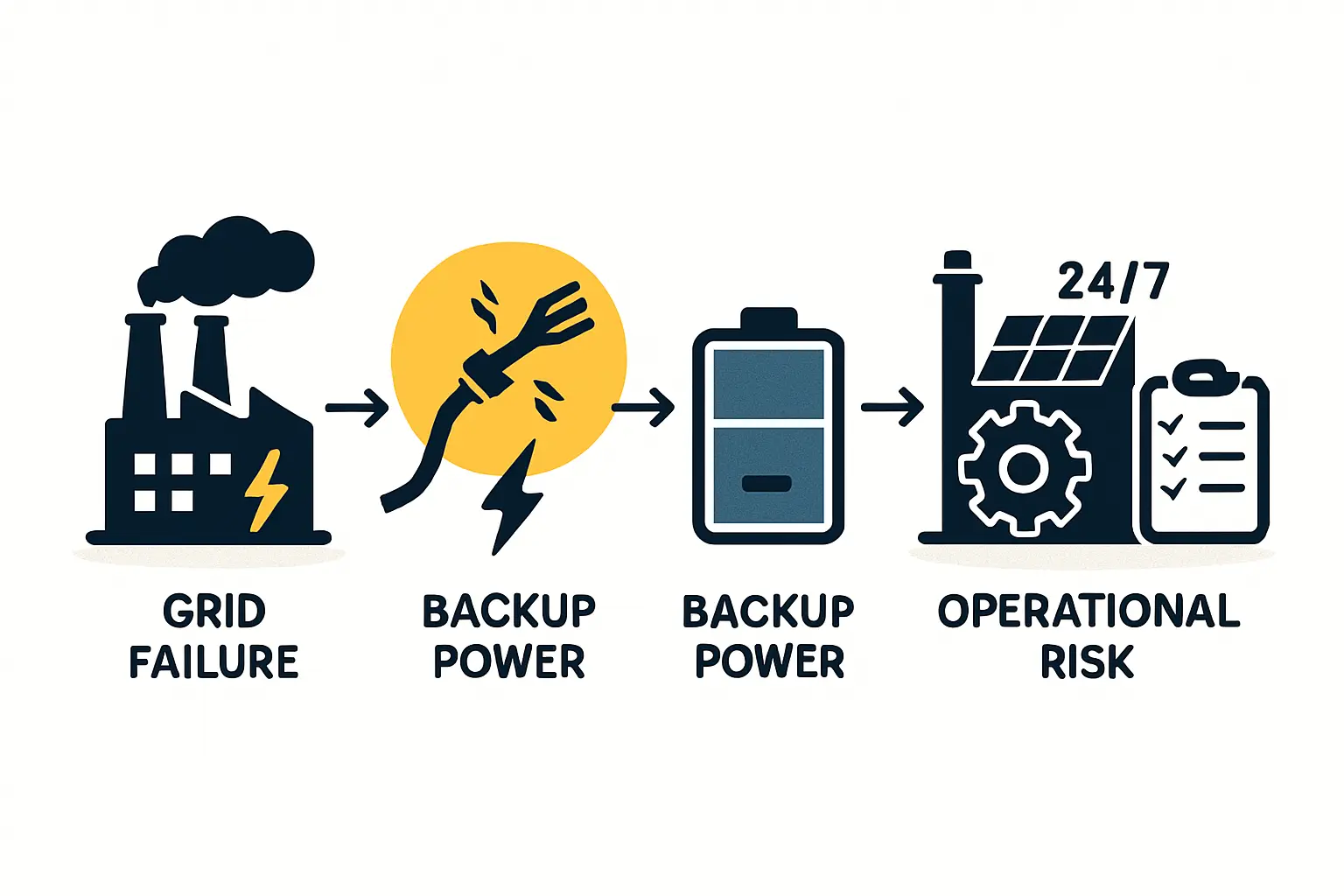

Imagine a factory manager receiving a call at 3 AM: the power grid has failed again, halting the entire 24/7 operation. In a market like Cuba, this scenario isn’t a distant possibility—it’s a central operational risk that must be addressed from day one.

For any investor considering solar manufacturing in Cuba, understanding the country’s infrastructure is not a technical footnote; it is the bedrock of a viable business plan. This assessment examines the two most critical pillars—electrical stability and transport logistics—and outlines practical strategies for mitigating their inherent risks.

The Paradox of Solar Manufacturing in an Energy-Deficient Market

Cuba’s ambition to generate nearly a third of its electricity from renewable sources by 2030 presents a significant opportunity. Decades of reliance on aging, oil-fired thermoelectric plants and challenges with fuel imports have left the country with an electrical grid notorious for instability and frequent outages.

This deficiency creates a robust, long-term domestic market for solar modules.

The situation, however, presents a paradox for manufacturers: the unstable grid that drives demand for solar products is also the greatest threat to producing them. Modern solar module manufacturing is an energy-intensive process where an uninterrupted power supply is non-negotiable.

Power Stability: The Foundation for 24/7 Production

A solar module assembly line is not a simple workshop; it involves sensitive, automated machinery that must operate continuously to maintain quality and throughput. Processes like solar cell stringing and, most critically, lamination are highly susceptible to power interruptions.

An unexpected shutdown during a lamination cycle can ruin the materials for a dozen or more modules—a direct and costly financial loss. A typical 20–50 MW solar factory requires a substantial and constant power draw. Any fluctuation or outage can lead to equipment damage, production downtime, and compromised product quality.

Analyzing Cuba’s National Electrical Grid (Sistema Eléctrico Nacional – SEN)

Cuba’s SEN faces systemic challenges. A significant portion of its generating capacity comes from decades-old thermoelectric plants that are inefficient and prone to failure. This reliance on imported heavy fuel oil also makes the grid vulnerable to global price shocks and supply chain disruptions.

While the government is actively working to integrate renewables, the existing infrastructure remains fragile and will require years of modernization. For a factory requiring 24/7 power, relying solely on the national grid is not a viable strategy.

Risk Mitigation Strategies for Power Supply

A resilient factory must engineer its own energy security. Based on experience from J.v.G. turnkey projects in regions with similar challenges, a multi-layered approach proves most effective.

-

On-Site Backup Generation: Industrial-grade diesel generators are not optional extras; they are an essential component of the primary power system. They must be sized to run the entire factory for extended periods, not just to bridge short-term outages. This requires careful planning for on-site fuel storage and reliable supply chains.

-

Hybrid Power Systems: A forward-thinking strategy integrates the factory’s own product into its power solution. A dedicated solar array, coupled with a Battery Energy Storage System (BESS), can provide a critical buffer. This system can smooth out grid fluctuations, handle short-term outages, and reduce dependence on diesel fuel during daylight hours, lowering operational costs.

-

Strategic Site Selection: The factory’s location is paramount. Proximity to a stable electrical substation or major industrial zone can make a significant difference. Conducting on-site power quality measurements before committing to a location is therefore a critical part of the initial analysis.

Logistics and Transport: Moving Materials In and Modules Out

A solar factory is a hub in a global and local supply chain. It requires a constant flow of raw materials—such as solar cells, glass, aluminum frames, and encapsulants—nearly all of which are imported. At the same time, it must efficiently distribute finished modules to project sites across the country.

A bottleneck at any point can starve the production line or leave the warehouse full of undeliverable products.

Assessing Cuba’s Port and Customs Infrastructure

The majority of raw materials will arrive by sea. While the Mariel Special Economic Development Zone (ZEDM) offers a modern container terminal and is a primary gateway, investors must plan for the realities of customs and administrative processes.

A standard 40-foot container holds materials for approximately 700–800 kW of solar modules. A 50 MW factory would need to import and process over 60 such containers annually for its core components alone. Even minor, unanticipated delays in customs clearance can halt production for weeks. Building a detailed logistics plan is a core element of a successful factory launch.

Inland Transportation Challenges and Solutions

Once materials clear the port, they must be transported to the factory. Assessing the condition of Cuba’s road and rail networks along planned routes is essential. Key considerations include:

- Road weight and height restrictions.

- The condition of bridges along the route.

- Seasonal disruptions, like those during hurricane season, which can interrupt transport for days.

The most effective mitigation strategy is to maintain a significant buffer stock of critical raw materials. Holding a two-to-three-month supply of solar cells, EVA, and backsheets provides a crucial cushion against unforeseen shipping or customs delays, ensuring production can continue uninterrupted.

A Framework for Due Diligence

Before committing significant capital, a thorough infrastructure audit is essential. This process should include:

- Power Audit: On-site analysis of grid stability at potential locations, including measurements of voltage and frequency fluctuations over several weeks.

- Logistics Audit: Detailed route surveys from the port to the proposed factory site, consultations with local freight forwarders, and a clear understanding of average customs clearance times.

- Regulatory Audit: Clarification of import tariffs on raw materials and manufacturing equipment, permitting for large-scale diesel generators, and any specific incentives or regulations within zones like Mariel.

Frequently Asked Questions (FAQ)

Why can’t a solar factory just run on its own solar panels?

Solar manufacturing is a 24/7 process, while solar panels only generate power during the day. Although a large solar array can significantly reduce daytime energy costs, running a factory through the night would require an exceptionally large and cost-prohibitive battery storage system for full autonomy. A more financially viable approach is a hybrid system that combines grid power, backup generators, and a solar-plus-battery system to ensure reliability and manage costs.

Is the Mariel Special Economic Zone the only viable location in Cuba?

Mariel offers compelling advantages with its modern port, streamlined customs, and potentially better infrastructure, but it’s not the only option. Other locations may be viable if a comprehensive plan is in place to manage power and logistics. The final decision depends on factors like land cost, labor availability, and proximity to the primary domestic market for finished modules.

How do these challenges affect the initial investment cost?

The investment must account for more than just production machinery. The budget needs to expand beyond the manufacturing equipment to include a robust power infrastructure (industrial generators, transformers, potentially a BESS) and the working capital to hold a larger-than-usual inventory of raw materials. These are essential costs for de-risking the project in such an environment.

Conclusion: Turning Challenges into a Competitive Advantage

Cuba’s infrastructure presents undeniable challenges for any industrial enterprise. Yet these obstacles are not insurmountable; they are manageable business risks that require diligent planning and strategic investment.

An investor who performs rigorous due diligence and engineers a resilient operational framework from the outset can build a highly successful and competitive manufacturing facility. In a market with such clear and growing demand for renewable energy, the ability to reliably produce high-quality solar modules locally is a powerful advantage. A successful Cuban solar factory will be built not just on advanced machinery, but on a solid foundation of thoughtful infrastructure planning.