An investor has identified the Czech Republic as a prime location for a new solar module factory. Its central European location, skilled industrial workforce, and supportive EU policies create a compelling business case. With land selected and financial models looking promising, the project seems ready to launch.

However, between this initial vision and the first day of construction lies a critical, often underestimated phase: navigating the country’s detailed administrative and environmental permitting process.

For entrepreneurs and companies new to the region, this journey can be complex. It isn’t merely a formality but a structured sequence of legal and technical approvals. Misunderstanding these requirements often leads to significant delays and budget overruns, turning a promising venture into a challenging one. This guide outlines the key steps, regulations, and practical considerations for securing the necessary permits for a solar manufacturing facility in the Czech Republic.

The Regulatory Framework: Key Czech Legislation

Effective planning for any construction project in the Czech Republic starts with understanding the key legislation governing the process.

-

The Building Act (No. 183/2006 Coll., Stavební zákon): This primary law governs all construction activities, defining the entire process from initial land-use decisions to the final occupancy permit. Its intricate and frequently amended nature requires careful attention.

-

The Environmental Impact Assessment (EIA) Act (No. 100/2001 Coll.): For projects of a certain size and type, including industrial manufacturing, this act mandates an assessment of potential environmental effects before major permits can be granted.

-

The Integrated Pollution Prevention and Control (IPPC) Act (No. 76/2002 Coll.): This legislation is particularly relevant for a solar factory. It requires industrial facilities to obtain a single “integrated permit” that covers all aspects of pollution control—air, water, and waste—based on the Best Available Techniques (BAT).

These laws create a sequential approval system where one permit often serves as a prerequisite for the next, making a structured approach essential.

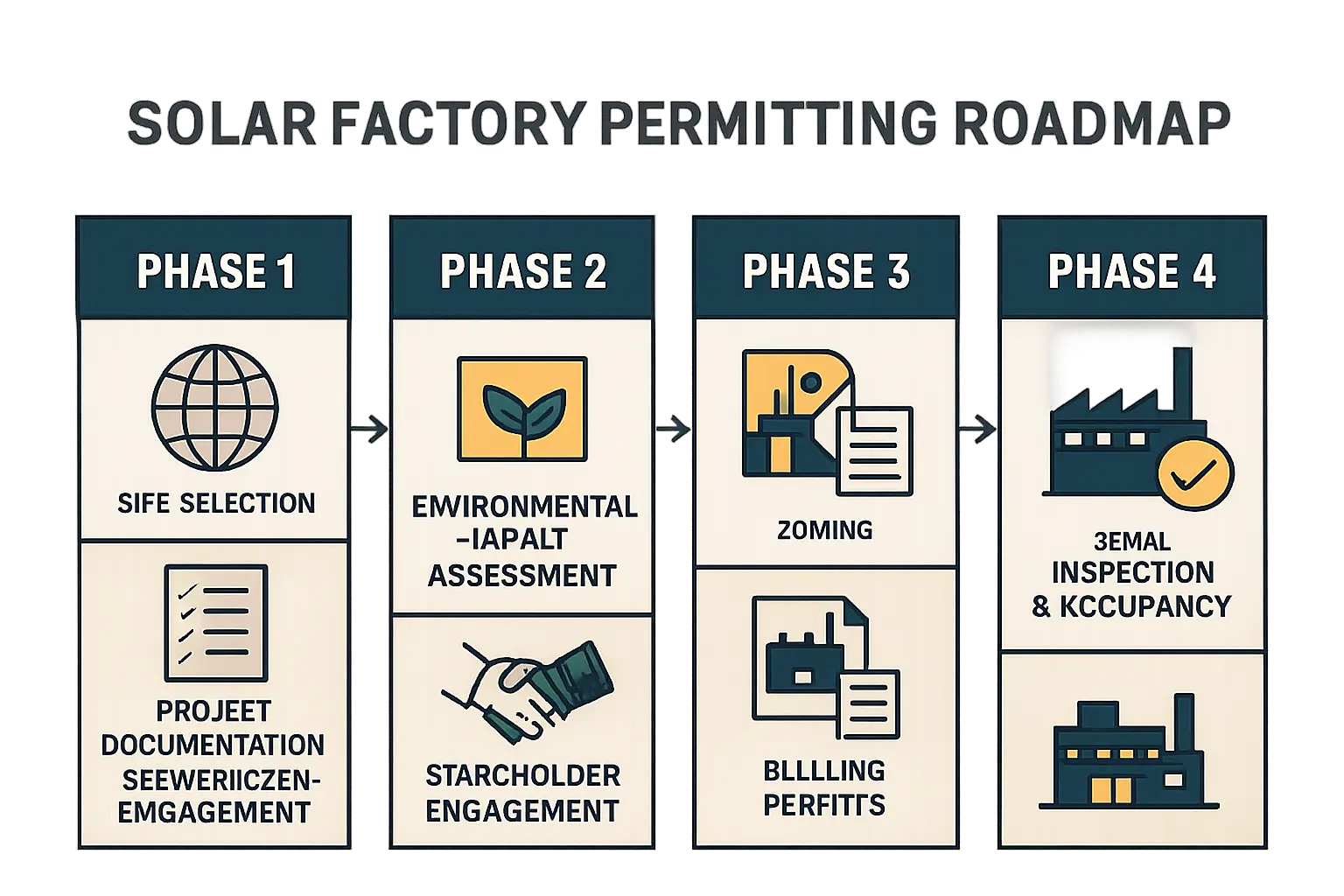

The Core Permitting Journey: From Zoning to Construction

The path to obtaining a building permit is typically a two-phase process managed by the local Building Office (stavební úřad).

Phase 1: Securing the Zoning Permit (Územní Rozhodnutí)

Before any detailed construction plans are approved, the project must first receive a Zoning Permit. This decision confirms that the proposed factory complies with the municipality’s long-term land-use plan.

It essentially answers the question: “Is this type of industrial facility allowed on this specific parcel of land?”

To secure this permit, an applicant must submit a comprehensive package, including:

- A detailed project description and its intended use.

- Site plans illustrating the factory’s placement and connection to infrastructure.

- Proof of land ownership or legal right to build.

- Binding statements from utility providers (electricity, water, gas) and other relevant authorities confirming their capacity and approval.

Obtaining the Zoning Permit is the first major administrative milestone, laying the foundation for the building permit application.

Phase 2: Obtaining the Building Permit (Stavební Povolení)

With a valid Zoning Permit in hand, the investor can proceed to apply for the Building Permit—the official authorization to begin construction. The documentation required at this stage is far more technical and detailed, forming the complete blueprint for the facility.

Key documents include:

- Complete architectural and engineering drawings.

- Structural analysis and technical specifications.

- A comprehensive Fire Safety Report, approved by the regional fire department.

- Statements confirming compliance with public health and hygienic standards.

The Building Office reviews this application in coordination with numerous other specialized authorities. A well-defined [Internal Link: solar factory layout] and thoroughly prepared technical documentation are critical for a smooth review process.

Essential Environmental Approvals for Industrial Operations

Parallel to the construction permitting process, a solar factory must clear significant environmental hurdles. These are not optional add-ons but core requirements for any industrial operation.

The Environmental Impact Assessment (EIA)

For a new manufacturing facility of this size, an Environmental Impact Assessment is often mandatory. The process begins with a “screening” phase, where the environmental authority determines if a full EIA is necessary based on the project’s scale, location, and potential impact.

If a full assessment is mandated, it involves:

- Scoping: Defining the key environmental areas to be studied.

- Detailed Assessment: An expert-led study of potential impacts on air quality, water resources, noise levels, and local ecosystems.

- Public Consultation: A mandatory period where the public and municipalities can review the EIA report and submit comments.

The EIA process can be lengthy, and a positive outcome is a prerequisite for securing other key permits, including the integrated permit and the building permit.

The Integrated Permit (IPPC)

A solar module factory is classified as an industrial activity that requires an Integrated Permit under the IPPC Act. This is a single, comprehensive environmental license to operate. It consolidates multiple environmental approvals into one, covering:

- Air emission limits.

- Wastewater discharge standards.

- Waste management plans.

- Energy efficiency measures.

The application must demonstrate that the factory will use the “Best Available Techniques” (BAT) to prevent or minimize its environmental footprint. Securing this permit often hinges on specifying the use of [Internal Link: modern PV manufacturing equipment] that meets high efficiency and environmental standards.

Practical Realities: Timelines, Challenges, and Strategic Planning

Based on experience from J.v.G. turnkey projects, the total timeline for securing all necessary permits can range from 6 to 18 months. This wide range depends on the project’s complexity, whether a full EIA is required, and the efficiency of local authorities.

Common Pitfalls to Avoid:

-

Incomplete Documentation: This is the most common cause of delays. Czech authorities require precise and complete information, and any omission will halt the process.

-

Underestimating Timelines: Investors commonly underestimate these administrative phases. Prudent business planning should account for the upper end of this timeline.

-

Language Barrier: All official applications, communications, and proceedings are conducted in Czech. Attempting to navigate this without professional, native-speaking support is a significant risk.

-

Grid Connection Agreement: This agreement should be secured early in the process, as its technical requirements directly influence the factory’s design and are needed for permit applications.

Engaging local architects, environmental consultants, and legal advisors who are familiar with the Czech system is not just a recommendation; it is a critical success factor for foreign investors.

Frequently Asked Questions (FAQ)

What triggers the need for a full Environmental Impact Assessment (EIA)?

The requirement for a full EIA is typically triggered by project-specific thresholds related to production capacity, physical size, or location near sensitive areas. The regional environmental authority makes the final determination during an initial screening procedure.

Can the building and environmental permit processes run in parallel?

To some extent. For example, preparation for the Building Permit can occur while the EIA is underway. However, the final issuance of the Building Permit is legally dependent on the successful completion of the EIA and the granting of the Integrated Permit.

What is the single most common reason for delays in the Czech Republic?

By far the most common cause of delays is submitting incomplete or inaccurate documentation to the authorities. This leads to formal requests for supplementary information, which resets review clocks and can postpone decisions by several months.

How important is having a local partner or consultant?

It is essential. Local experts understand the nuances of the law, have established relationships with authorities, and can navigate the entire process in the Czech language. Their involvement significantly reduces the risk of errors and delays.

Does the Czech government offer “fast-track” options for renewable energy projects?

While political support for renewables is strong, driven by initiatives like the EU’s REPowerEU plan, the fundamental administrative framework of the Building Act remains in place. There may be specific incentives or priority handling, but projects must still complete all standard legal and technical requirements.

Conclusion: Laying the Foundation for a Successful Investment

Establishing a solar factory in the Czech Republic involves a rigorous, multi-stage permitting process that demands careful planning and expert guidance. While the regulations are detailed, they are clear and manageable when approached with a thorough understanding of the requirements and realistic timelines.

Successfully navigating the Zoning Permit, Building Permit, EIA, and IPPC processes is more than an administrative hurdle; it is the strategic foundation for a compliant, sustainable, and successful manufacturing operation. Understanding these administrative steps is a core part of developing a comprehensive [Internal Link: solar factory business plan] and is the first concrete step toward turning a powerful vision into a productive reality.