An entrepreneur exploring new manufacturing ventures might see Djibouti primarily as a strategic port. Its location on one of the world’s busiest shipping routes is an undeniable asset.

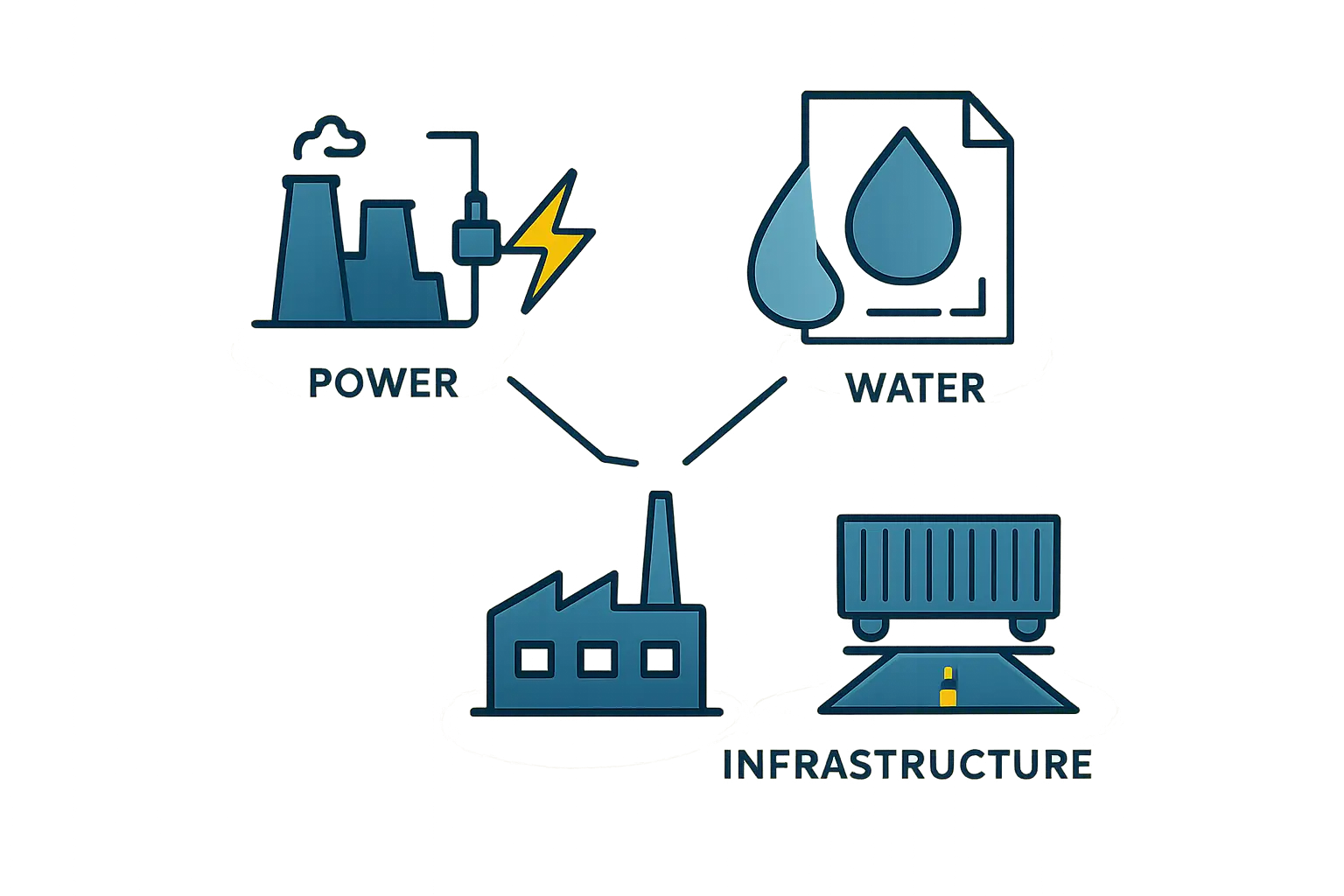

However, a successful industrial operation like a solar module factory depends less on the port itself and more on the quality of the infrastructure supporting the factory floor. The difference between a profitable venture and a costly failure often lies in the due diligence on three fundamental pillars: power, water, and transport logistics.

This guide offers a framework for assessing industrial site suitability in Djibouti, focusing on the practical infrastructure requirements any manufacturing investment depends on. It moves beyond high-level advantages to examine the granular details that directly impact operational costs and long-term viability. For those considering the solar industry, understanding these local conditions is the first step in a successful planning process—a subject explored further in our guide on how to start a solar module factory.

The Strategic Advantage: Why Djibouti’s Location Matters

Djibouti’s geographical position at the nexus of the Red Sea and the Gulf of Aden offers significant logistical benefits. It serves as a critical gateway to East Africa—particularly for landlocked Ethiopia, with which it is connected by a modern railway.

For a solar module manufacturer, this presents two key opportunities:

-

Efficient Inbound Logistics: The primary raw materials for solar panel production, such as solar glass, aluminum frames, and photovoltaic cells, are typically imported. A site near a major international port like the Port of Djibouti streamlines this supply chain, reducing both lead times and transportation costs. The intricacies of this process are detailed in guides on raw material sourcing for solar panels.

-

Access to Regional Markets: Finished solar modules can be efficiently exported to growing markets across Africa and the Middle East by leveraging the existing maritime infrastructure.

While the port is a world-class asset, a factory’s success hinges on the infrastructure connecting it to the proposed site and the utilities available on-site.

Evaluating Critical Infrastructure: A Step-by-Step Analysis

A thorough site assessment examines the availability, reliability, and cost of essential utilities. In Djibouti, this analysis reveals both challenges and opportunities that must be factored into any business plan.

Power Supply: The Cost and Reliability Equation

Reliable electricity is the lifeblood of any manufacturing facility. For a solar module production line, which uses sophisticated machinery like laminators and cell stringers, both the stability and the cost of power are critical.

Djibouti’s energy landscape presents a significant challenge:

-

High Electricity Costs: The country has historically relied on imported fossil fuels for power generation, resulting in some of the highest electricity tariffs in the region. Industrial electricity costs can reach as high as $0.22 per kilowatt-hour (kWh), a substantial operational expense that directly impacts profitability.

-

Grid Stability: While improving, grid stability can be a concern in certain areas. Production line interruptions from power outages can lead to material waste and decreased output.

However, the government is actively pursuing a transition to renewable energy, with the goal of sourcing 100% of its energy from renewables by 2035. Projects like the 60 MW Ghoubet wind farm and the planned 30 MW Grand Bara solar park signal strong momentum.

For an investor, this means planning for the present reality of high costs while anticipating a future with greater energy independence and potentially lower prices. A common strategy seen in J.v.G. Technology GmbH projects is to incorporate a captive solar power plant for self-consumption, using the factory’s own roof to generate electricity and mitigate exposure to high grid tariffs.

Water Resources: Managing a Scarce Commodity

Djibouti is one of the most water-scarce nations in the world, an environmental reality with direct implications for industrial site selection. While solar module manufacturing is not as water-intensive as other industries, it still requires a consistent supply of high-purity water, primarily for cleaning solar glass before the lamination process.

Key questions for assessment include:

-

Source and Availability: What is the source of water for the proposed industrial zone? Is it from municipal supplies, boreholes, or desalination?

-

Cost: Water, especially from desalination, carries a significant cost tied to the energy required for its production. This must be factored into the operational budget.

-

Quality: The water may require further purification on-site to meet the stringent standards for module production, adding another layer of capital and operational expenditure.

Failure to secure a reliable and affordable water source can become a critical operational bottleneck.

Transport and Logistics: From Port to Production Floor

Excellent port infrastructure is valuable only if an efficient ‘last-mile’ network connects it to the factory. The assessment must include a physical evaluation of the roads, rail access, and travel time between the port and potential sites.

Key considerations include:

-

The condition of roads for heavy truck traffic carrying sensitive materials like large panes of glass.

-

Proximity to the main arterial routes connecting to the port and the Ethiopian railway.

-

Potential bottlenecks or congestion points that could delay shipments.

A site that appears ideal on a map may prove impractical if the connecting infrastructure is inadequate. This is a crucial aspect of solar factory building requirements, as accessibility directly impacts both the construction and operational phases.

A Framework for Site Selection

A structured approach to site assessment minimizes risk and clarifies investment decisions. Breaking the process into logical stages ensures all critical factors are considered before any significant capital is committed. This systematic evaluation transforms a complex decision into a manageable process, often forming the foundation of a bankable business plan for a turnkey solar production line.

Frequently Asked Questions (FAQ)

What are the primary operational risks when setting up a factory in Djibouti?

The main operational risks stem from the high costs of electricity and water. A business model must demonstrate profitability despite these high input costs, often through efficiency measures or the self-generation of power.

Does the government of Djibouti offer incentives for renewable energy manufacturing?

The government is actively promoting foreign investment in its renewable energy sector as part of its Vision 2035 strategy. Investors should engage with the National Investment Promotion Agency (NIPA) to inquire about specific incentives, tax benefits, or support for projects aligned with national goals.

Can a solar module factory in Djibouti run entirely on its own solar power?

A factory can significantly reduce its reliance on the grid by installing a large rooftop or ground-mounted solar system. However, achieving 100% autonomy is challenging due to the 24/7 power needs of some equipment and the intermittency of solar. A hybrid approach that combines a captive solar plant with a grid supply is an effective strategy for cost reduction.

What is the single most important factor to verify during a site visit?

While all factors are important, the most critical element to verify on the ground is the ‘at-the-meter’ reality of the power supply. This includes confirming the actual tariff structure with the utility provider (Électricité de Djibouti – EDD), assessing the physical condition of the local grid connection, and understanding any historical data on power outages in that specific area.