For an entrepreneur on Dominican soil, the landscape is ripe with opportunity. The strong Caribbean sun shines on a nation where high electricity costs fuel a growing appetite for energy independence. Meanwhile, the island’s major ports offer a direct connection to the world’s largest consumer market and a network of neighboring countries.

The question isn’t whether to build a solar module factory, but for whom. Should the focus be inward, serving a burgeoning local demand? Or outward, leveraging powerful trade agreements to become an export hub? This strategic decision will shape everything from the factory’s scale and technology to its financial model—a choice that hinges on several critical factors.

The Dominican Republic’s Strategic Position

The Dominican Republic offers more than abundant sunshine; its geography and political standing create a compelling business case for solar manufacturing. The opportunity rests on two key advantages: a robust domestic market and preferential access to significant international ones.

A sound business strategy starts with understanding the dynamics of both. The country’s well-developed infrastructure, including major shipping ports like Caucedo and Haina, offers a logistical advantage for either a domestic or export-oriented operation.

Analyzing the Domestic Market Opportunity

Focusing on the local market is often the most direct path to entry. The demand is tangible, driven by clear economic and policy factors.

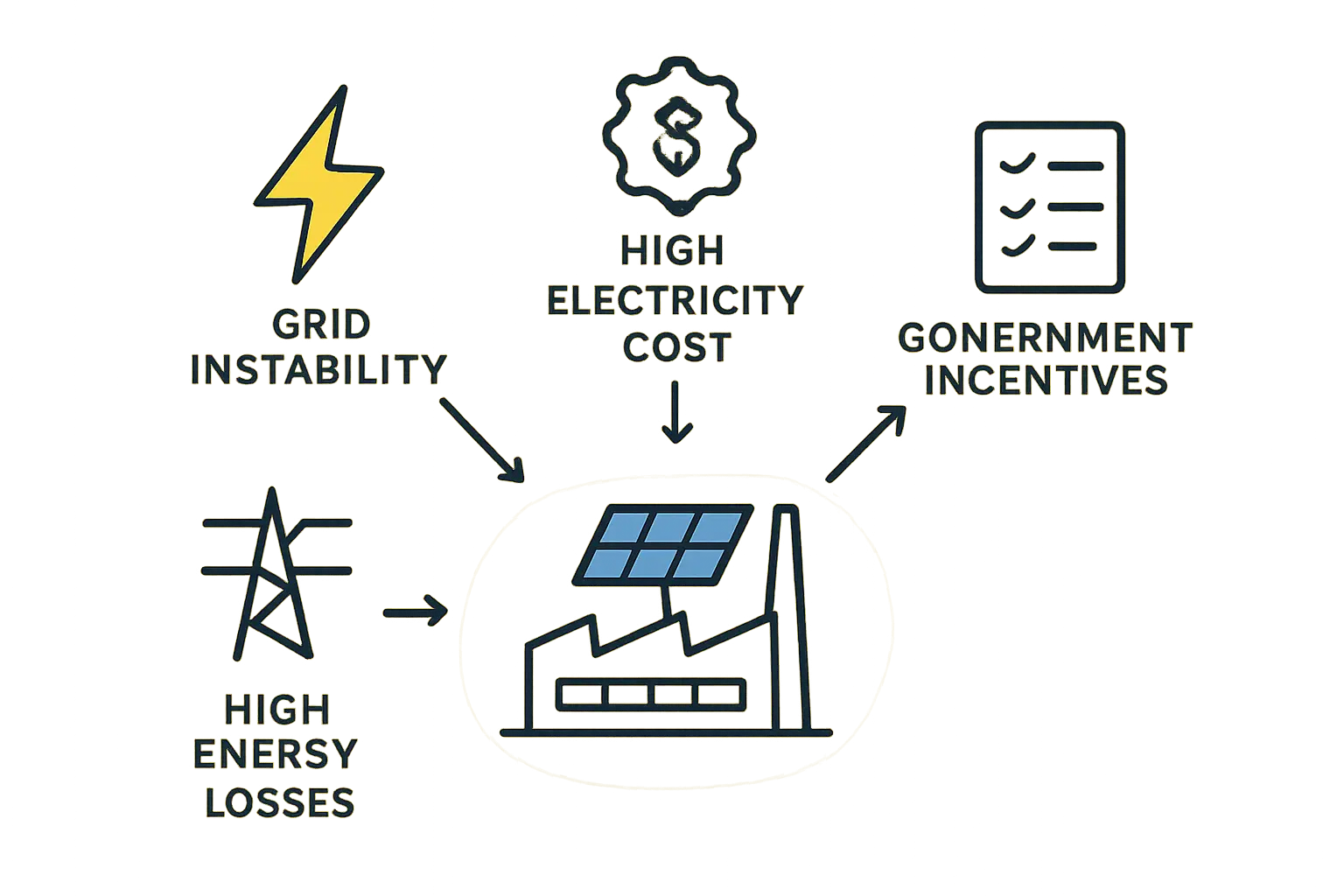

Drivers of Local Demand

-

High Electricity Costs: The Dominican Republic has historically faced some of the highest electricity prices in the region. This gives businesses and households a powerful financial incentive to adopt solar energy, reduce their operational expenses, and stabilize their budgets.

-

Government Incentives: Law 57-07 on Renewable Energy Incentives provides significant benefits, including tax exemptions for equipment and financing, accelerating the return on investment for solar projects.

-

National Energy Goals: The government’s National Energy Plan targets 25% of energy generation from renewable sources by 2025 and 30% by 2030. This policy creates a stable, long-term demand for solar modules.

Advantages of a Domestic Focus

Serving the local market allows a manufacturer to build a competitive edge through sheer proximity.

-

Reduced Logistics Costs: Eliminating international shipping, tariffs on imported competitor panels, and complex customs procedures can lead to lower final costs and higher margins.

-

Faster Delivery Times: Supplying modules quickly is a significant advantage over international competitors who face shipping delays of several weeks or months. This is particularly valuable for commercial and industrial projects with tight deadlines.

-

Direct Customer Relationships: Operating locally allows for a deeper understanding of customer needs, making it possible to offer tailored solutions and build a strong brand reputation based on service and reliability.

However, a domestic-only strategy means the factory’s growth is ultimately tied to the size and pace of the local market.

Exploring Export Markets: DR-CAFTA & CARICOM

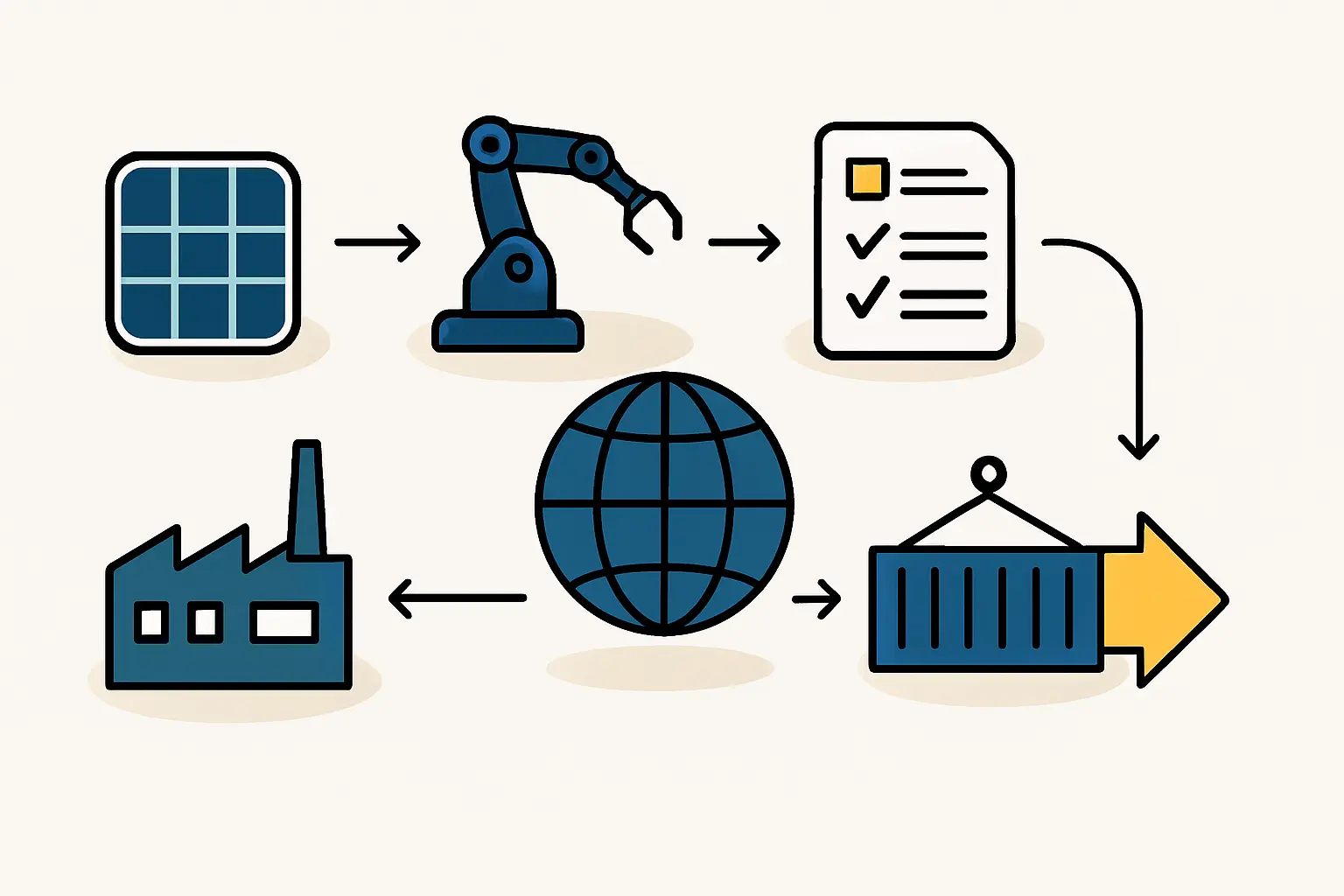

An export-oriented strategy leverages the Dominican Republic’s trade agreements to access a much larger potential customer base. This approach transforms the factory from a local supplier into a regional player.

The DR-CAFTA Advantage: Access to the United States

The Dominican Republic-Central America Free Trade Agreement (DR-CAFTA) is arguably the most significant asset for an export strategy. Its members include the United States, Costa Rica, El Salvador, Guatemala, Honduras, and Nicaragua.

For a solar module manufacturer, the primary benefit is preferential access to the U.S. market—one of the largest in the world. By manufacturing in the Dominican Republic, products may qualify for reduced or zero tariffs when exported to the U.S.

To benefit, however, manufacturers must comply with ‘Rules of Origin,’ which require that a specified percentage of a module’s value must be created within the DR-CAFTA region. This often involves sourcing certain components locally or regionally and ensuring the assembly process adds sufficient value. This requirement is a critical factor when planning the factory’s supply chain and production design.

The CARICOM Opportunity: Serving the Caribbean

The Caribbean Community (CARICOM) is a free trade agreement connecting the Dominican Republic with 15 member states throughout the Caribbean. While individual island markets are small, their collective need is substantial.

Like the Dominican Republic, these nations face high energy costs and vulnerability to fossil fuel price volatility. Many are actively pursuing renewable energy to improve energy security and resilience. A Dominican-based manufacturer is perfectly positioned to serve this region with lower shipping costs and faster response times than competitors from Asia or Europe.

Key Business Considerations for Each Path

The choice between a domestic and export focus has direct implications for the factory’s setup and operations.

Production Scale and Investment

-

Domestic Focus: A smaller production line, perhaps in the 20-50 MW range, can effectively serve the local market. This requires a more modest upfront capital outlay.

-

Export Focus: To be competitive in the U.S. market, a larger scale (e.g., 100-200 MW or more) is often necessary to achieve lower production costs per unit. This significantly increases the required investment.

Product Certification

-

Domestic Focus: Modules will need to meet local Dominican standards (if any) and possibly a basic international standard like IEC to gain market trust.

-

Export Focus: Accessing the U.S. market requires mandatory UL certification, a rigorous and costly process. Each CARICOM country may also have its own specific import requirements. An export strategy must account for the significant cost and time involved in obtaining these certifications.

Sales and Distribution

-

Domestic Focus: Requires building a local sales team, establishing relationships with installers and project developers, and creating a recognized local brand.

-

Export Focus: Involves finding international distribution partners, navigating export logistics, managing currency exchange, and complying with different legal and commercial frameworks in each target country.

Of course, these paths are not mutually exclusive. A hybrid strategy is often the most practical approach, allowing a factory to first establish itself in the Dominican market to generate cash flow and build operational experience. Once its processes are stable and the brand is recognized, it can strategically expand into export markets, first within CARICOM and then potentially to the U.S. under DR-CAFTA.

Frequently Asked Questions (FAQ)

What are ‘Rules of Origin’ and why do they matter for a solar factory?

Rules of Origin are criteria used to determine the national source of a product. Under trade agreements like DR-CAFTA, for a product to receive tariff-free treatment, a certain amount of its value must originate from within the member countries.

For a solar module factory, this means you cannot simply import all components from Asia, assemble them, and expect to qualify. You must demonstrate sufficient local value-add through labor, local materials, or processing. This is a critical legal and logistical requirement for an export strategy.

Do I need different solar panel certifications for each market?

Yes, very likely. The Dominican domestic market may have its own set of standards, but for export, you must meet the specific requirements of the destination country. For instance, the United States requires UL certification for grid-tied solar equipment, which is a different and more extensive process than the IEC certification commonly accepted in Europe and other parts of the world.

Is it feasible to serve both domestic and export markets from one factory?

Absolutely. This is a common and often sensible growth strategy. Many manufacturers start by satisfying local demand to prove their product and stabilize their business. As they grow, they can allocate a portion of their production to export, leveraging their location and trade agreements to expand their reach.

How can a local Dominican manufacturer compete with large-scale imports from Asia?

A local manufacturer competes on factors other than pure price-per-watt. Key advantages include:

-

Speed and Availability: Immediate product availability without long ocean transit times.

-

Logistics Savings: No international shipping costs or import tariffs paid by customers.

-

Customization: Ability to produce smaller, custom batches for specific projects.

-

Local Support: Offering local warranty service and technical support builds trust.

-

‘Made in the Dominican Republic’ Brand: For some government or private tenders, local production can be a specified advantage.

Making an Informed Decision

The decision to target domestic or export markets from the Dominican Republic is not simple. It hinges on an entrepreneur’s access to capital, tolerance for complexity, and long-term vision. The domestic market offers a clearer path to revenue, while the export market presents a much larger but more demanding opportunity.

Weighing the costs and benefits of each approach requires a thorough feasibility study and a detailed business plan. By carefully analyzing market drivers, investment requirements, and operational complexities, an entrepreneur can position a solar manufacturing business for sustainable success.