Imagine a batch of high-quality solar modules halfway through the critical 15-minute lamination cycle. Suddenly, the power cuts out. The heating and vacuum pressure drop, rendering the entire batch—worth thousands of dollars—unusable. For any entrepreneur planning to establish a solar module factory, particularly in a region with an unstable grid, this isn’t just a hypothetical risk. It’s a critical business challenge demanding a robust technical solution from day one.

This article explores the unique power infrastructure challenges in a market like the Dominican Republic and outlines the primary technical solutions for guaranteeing the uninterrupted power that’s essential for high-quality, efficient solar module production.

The High Cost of Unstable Power in Manufacturing

In the world of precision manufacturing, a consistent and clean power supply is not a luxury—it’s a fundamental requirement. The solar module manufacturing process involves several energy-intensive and time-sensitive stages. Key machines like laminators, stringers, and testers have specific power consumption profiles and are highly sensitive to voltage fluctuations or sudden outages.

A laminator, for example, requires stable power to maintain precise temperatures and pressures. An interruption can lead to delamination, bubbles, or other defects that compromise the final product’s quality and longevity. Similarly, automated cell stringing equipment can be damaged or misaligned by power surges, causing production delays and costly repairs.

The financial impact extends beyond a single lost batch to include equipment damage, reduced throughput, and potential reputational harm.

Understanding the factory’s load profile is the first step. Production lines typically have significant power peaks during the operation of laminators and final quality testing (flashing), while baseline consumption remains lower. A successful power strategy must accommodate these peaks without fail.

Understanding the Local Context: The Dominican Republic’s Grid

Any effective solution begins with understanding the specific problem. The Dominican Republic, while offering significant economic potential and excellent solar irradiance of 5.0 to 6.5 kWh/m²/day, faces well-documented challenges with its national electrical grid.

According to industry analysis and reports from international development agencies, the grid is characterized by:

-

High Technical and Commercial Losses: Losses often approach 30%, far exceeding the regional average. This points to inefficiencies in transmission and distribution.

-

Frequent Outages: Power interruptions, or apagones, are a common occurrence, stemming from aging infrastructure and generation capacity that sometimes struggles to meet peak demand.

-

Voltage and Frequency Fluctuations: Inconsistent power quality can damage the sensitive electronic equipment common in modern manufacturing lines.

These issues have a tangible economic cost, estimated in the hundreds of millions of dollars annually for the country’s economy. While the Dominican government is actively investing in grid modernization and renewable energy integration, businesses planning near-term operations must implement their own strategies for power reliability. For a solar module manufacturer, relying solely on the grid is simply not a viable business strategy.

Solar Manufacturing Plant in the Dominican Republic: A Technical Review” />

Solar Manufacturing Plant in the Dominican Republic: A Technical Review” />

Evaluating Power Redundancy Solutions

Fortunately, proven engineering solutions exist to create a stable power environment for a manufacturing plant, even with a challenging grid. The choice depends on balancing initial investment, long-term operational costs, and the desired level of reliability.

Option 1: The Conventional Approach – Backup Diesel Generators

The most traditional solution for backup power is the diesel generator. When a grid outage is detected, an automatic transfer switch (ATS) disconnects the factory from the grid and starts the generator to take over the load.

-

Advantages: Lower initial capital expenditure compared to other systems; the technology is well-understood and widely available.

-

Disadvantages: High and volatile operational costs tied to diesel fuel prices; requires regular, costly maintenance; produces significant noise and carbon emissions; a slight delay during power transfer can still affect sensitive equipment.

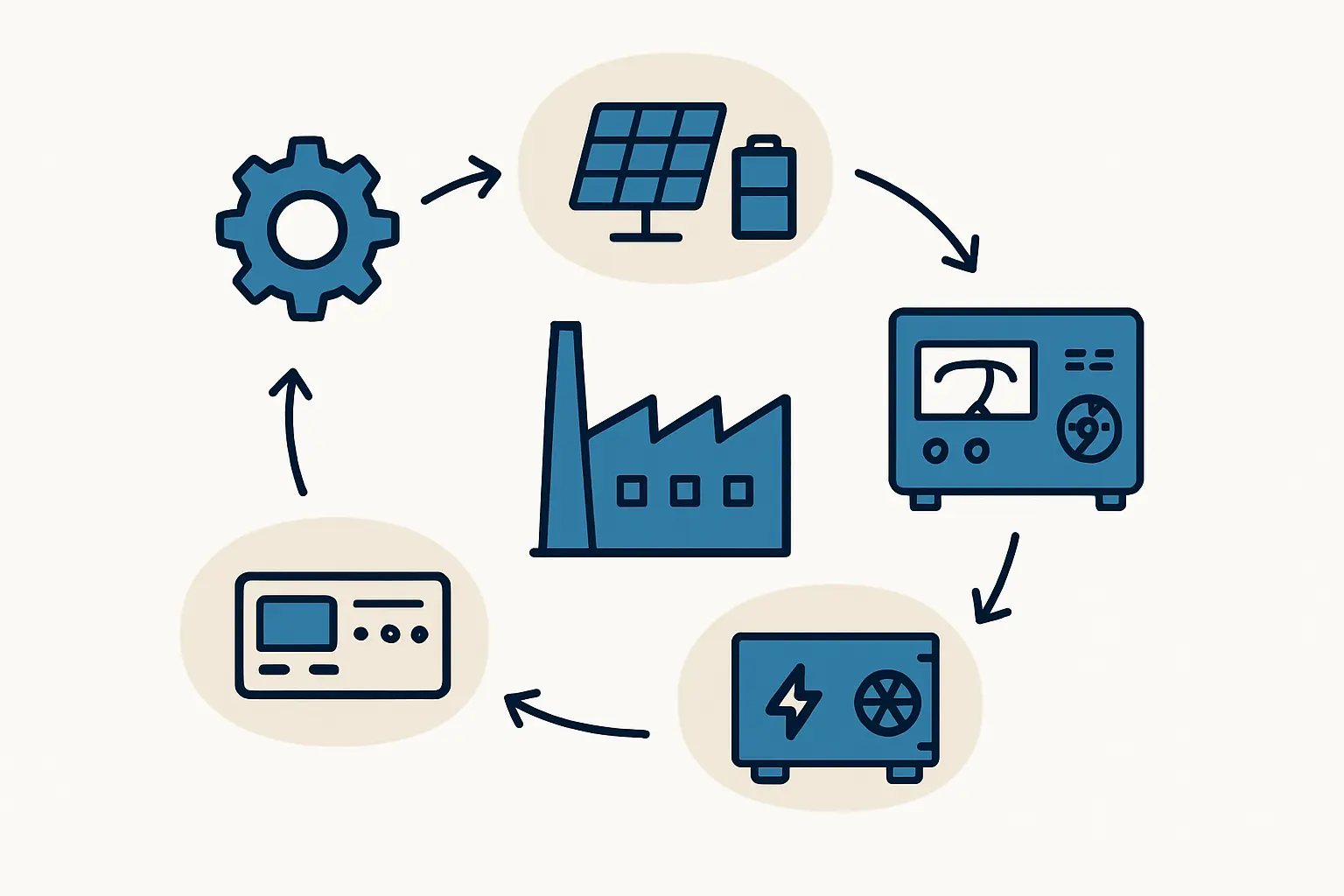

Option 2: The Sustainable Solution – On-Site Solar with Battery Storage (BESS)

A more modern approach involves leveraging the region’s primary natural resource: the sun. An on-site solar photovoltaic (PV) system, sized to meet a significant portion of the factory’s energy demand, is paired with a Battery Energy Storage System (BESS).

The BESS stores excess energy generated by the solar array during the day. It can then provide instantaneous, clean power during a grid outage, acting as an uninterruptible power supply (UPS).

-

Advantages: Achieves significant energy independence; drastically reduces long-term operational costs and exposure to volatile fuel prices; provides seamless, high-quality power without interruption; enhances the company’s environmental credentials.

-

Disadvantages: A higher initial capital investment is required for the battery system.

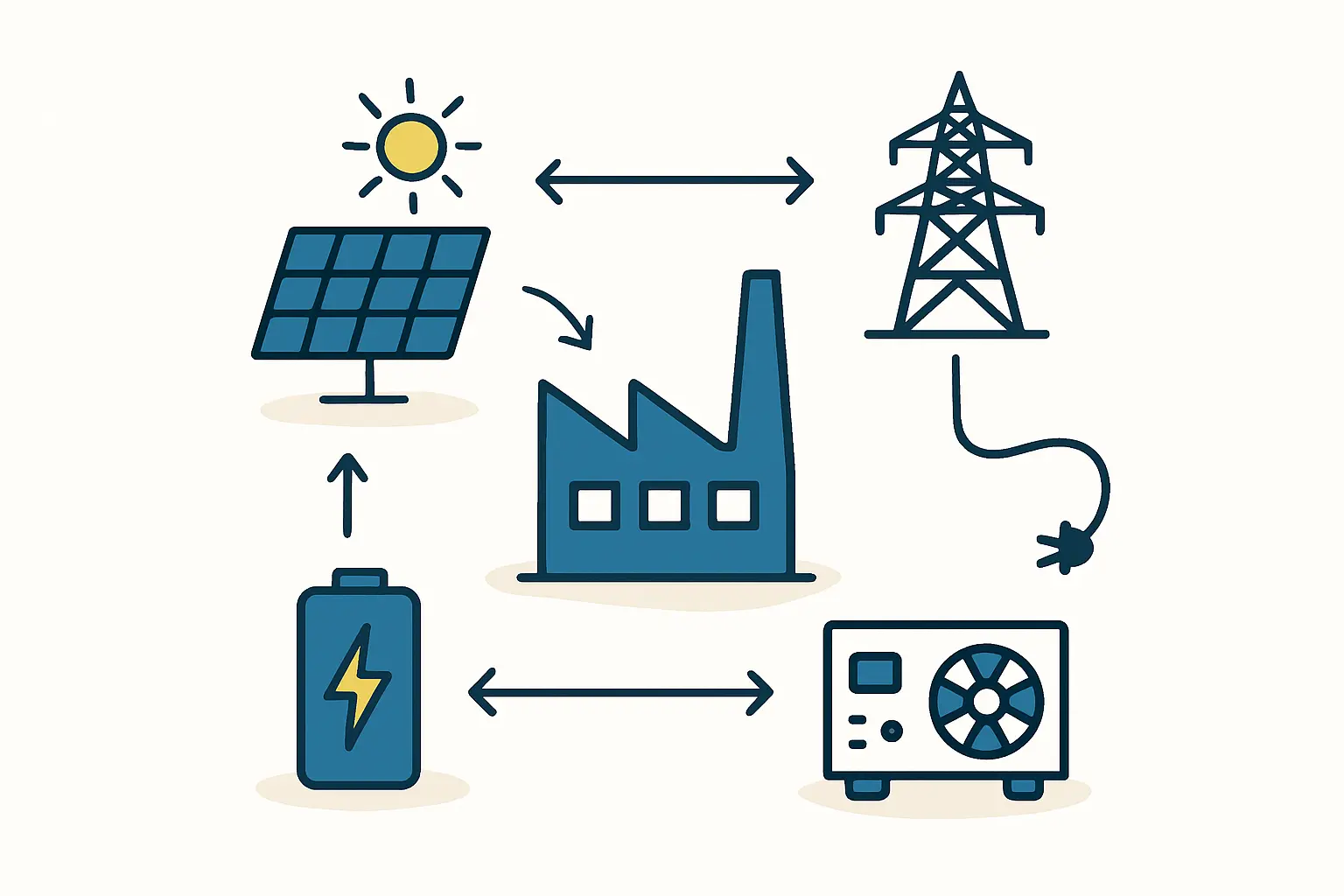

Option 3: The Ultimate Guarantee – A Hybrid Power System

For mission-critical operations where any downtime is unacceptable, a hybrid system offers the highest level of reliability. This approach integrates multiple power sources, all managed by an intelligent energy management system.

A typical hybrid configuration includes:

-

The Grid: Used as the primary power source when stable and cost-effective.

-

Solar PV Array: Generates electricity during the day, reducing grid consumption and operational costs.

-

Battery Energy Storage System (BESS): Acts as the first line of defense, providing instant power during grid failures and helping manage peak loads.

-

Backup Generator: Serves as a final redundancy, programmed to start only during prolonged grid outages after the BESS is depleted.

This multi-layered approach ensures the factory remains operational under virtually any circumstance, protecting production schedules and equipment integrity.

Integrating Power Strategy into Factory Planning

A robust power stability strategy shouldn’t be an afterthought—it’s a core component of the initial factory design and business plan. The physical space and electrical infrastructure for generators, solar arrays, and battery systems must be incorporated into the overall factory design.

Based on experience from J.v.G. Technology GmbH turnkey projects in regions with similar grid challenges, a hybrid power system often provides the optimal balance of reliability and long-term operational cost savings. When planning a turnkey production line, a thorough assessment of local grid conditions and a detailed energy-needs analysis are the first and most critical steps. This ensures the power solution is precisely tailored to the factory’s operational demands and the local environment.

Frequently Asked Questions (FAQ)

How much energy does a small-scale solar factory consume?

A 50 MW annual capacity solar module production line typically has a peak power demand of 250–400 kW, with an annual electricity consumption of approximately 1.0–1.5 GWh, depending on the specific technology and number of shifts.

What is the typical payback period for a solar-plus-storage system?

The payback period depends heavily on local electricity tariffs and the cost of diesel fuel. In markets with high energy costs and frequent outages, savings from reduced grid consumption and avoided diesel usage can lead to an attractive return on investment, often in the range of 5 to 8 years.

Can a solar factory be run entirely off-grid?

While technically possible, operating a factory of this scale completely off-grid would require a significantly oversized solar array and BESS to account for cloudy days and ensure 24/7 power availability, substantially increasing the initial investment. For most business cases, a grid-tied hybrid system that uses the grid as a backup is the most economically sound approach.

Does the choice of power system affect module certification?

The power system itself does not directly affect certification. However, an unstable power supply can lead to manufacturing inconsistencies that cause products to fail the stringent quality and performance tests required for certifications like IEC 61215. This makes a reliable power system an indirect prerequisite for consistent, certifiable production.

Planning for Uninterrupted Production

For any investor considering the solar manufacturing sector, especially in emerging markets, power stability is a foundational pillar of a successful venture. The challenges posed by an unreliable grid, such as the one in the Dominican Republic, are significant but manageable with proper technical planning and investment in the right infrastructure.

By evaluating the options—from conventional generators to advanced hybrid systems—and integrating this decision early into the business plan, entrepreneurs can mitigate a major operational risk. Understanding these foundational infrastructure requirements is a critical first step toward developing a robust and resilient manufacturing operation.