Establishing a solar module assembly plant in a region like Asmara is a significant business opportunity, a prospect backed by large-scale projections. A joint report by UNIDO and ECREEE estimates that renewable energy could create up to 26 million jobs in Africa by 2050, highlighting a path toward industrial development and local value creation. However, entrepreneurs often face a critical question: how do you build a technically proficient workforce where a specific industrial base may not yet exist?

It’s a valid concern. A World Bank report, “Skills for a Modern Eritrea,” notes a potential gap between formal education and the specific technical skills required by modern industry.

Yet, this gap is not an insurmountable barrier. Instead, it presents a unique opportunity to cultivate a highly skilled and dedicated workforce from the ground up. This article outlines a structured, three-phase blueprint for recruiting and training a local team in Asmara, transforming inexperienced individuals into qualified solar module assembly technicians. This process is a crucial component of the overall investment required for a solar module factory.

Understanding the Local Context: Asmara’s Potential and Challenges

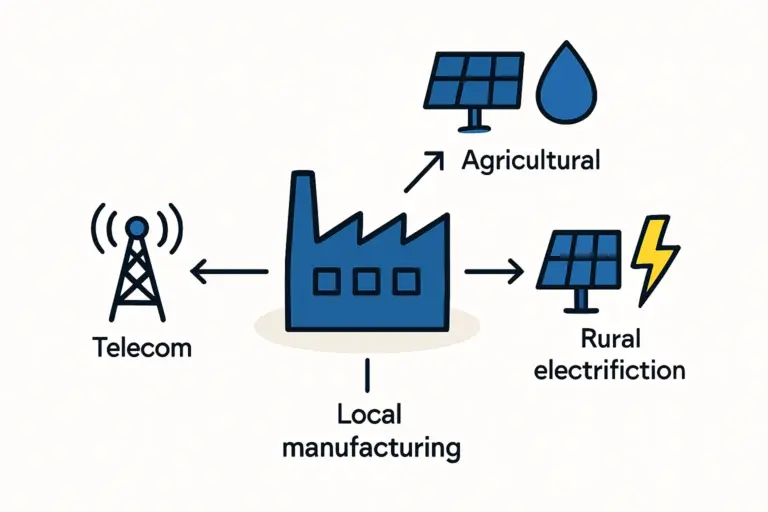

Launching a manufacturing venture in Eritrea means operating within a supportive policy framework. The nation’s Energy Policy emphasizes developing renewable energy sources and building local capacity. This alignment between private investment and national goals creates a favorable environment for projects focused on local employment and skills development.

The primary challenge, according to workforce analyses, isn’t a lack of potential so much as a need for targeted Technical and Vocational Education and Training (TVET). While the general labor pool may have strong foundational aptitudes, it often lacks direct experience with the automated machinery and stringent quality control protocols common in electronics assembly. Acknowledging this reality is the first step. The solution lies in a purpose-built, in-house training program that bridges this specific skills gap, rather than relying on pre-existing experience.

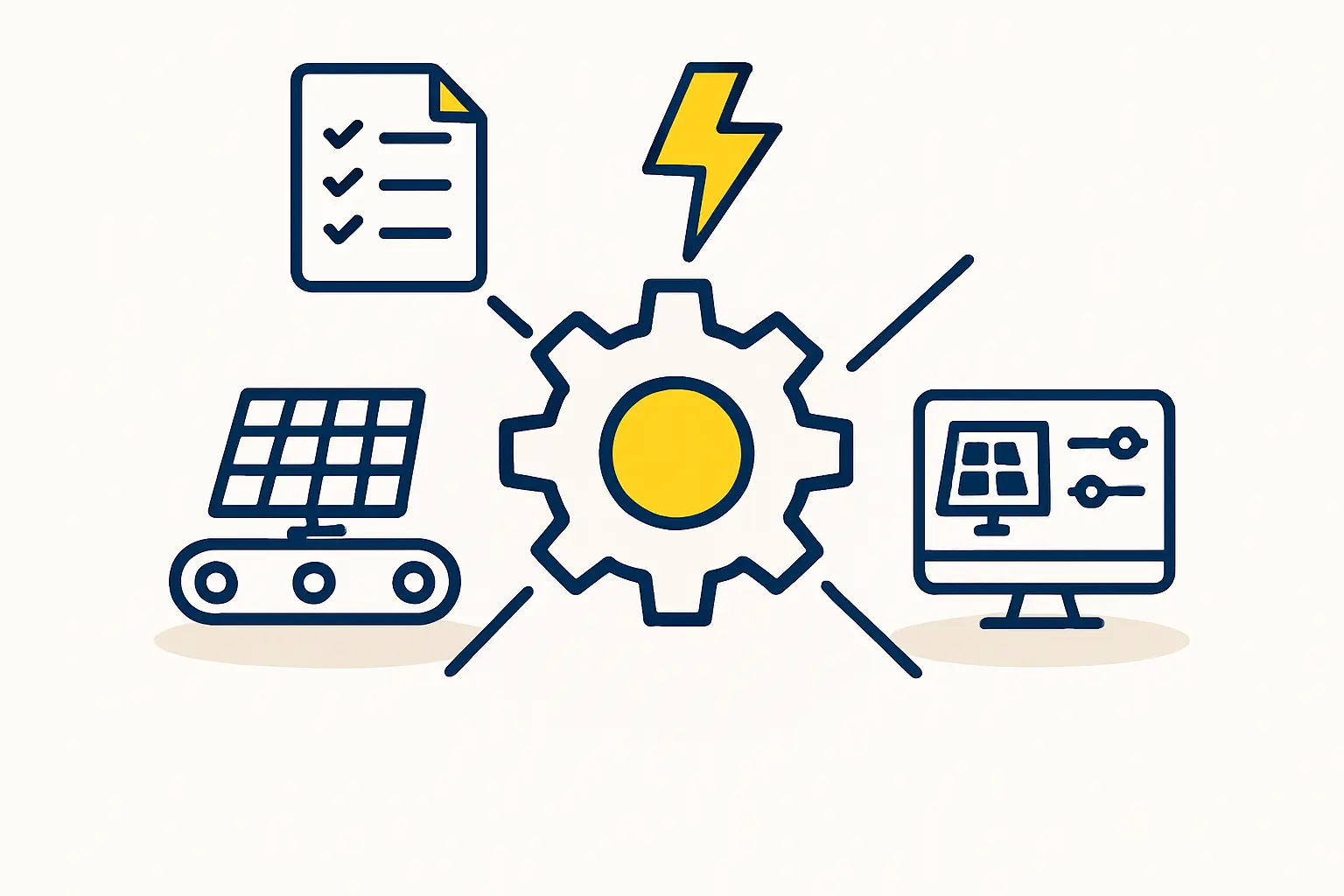

The Three-Phase Training Blueprint for Solar Module Assembly

Experience from J.v.G. Technology GmbH turnkey projects shows that a successful training program for a new workforce can be structured in three distinct phases. This model is designed for a team of 25–30 employees—the typical size for a 20–50 MW semi-automated production line—and is completed over a 4–6 week period.

Phase 1: Foundational Classroom Training (1-2 Weeks)

The journey begins not on the factory floor, but in a classroom. This initial phase builds a common foundation of knowledge while establishing a professional culture centered on safety and quality.

Key topics covered include:

- Fundamentals of Photovoltaics: Trainees learn the basic principles of how solar cells work and how modules generate electricity, giving them essential context for their work.

- Safety Protocols: Comprehensive training on workplace safety, including handling materials, electrical safety, and emergency procedures.

- Introduction to Quality Standards: The team is introduced to the concepts of ISO 9001 and the importance of process discipline. They learn why every step, no matter how small, affects the final product’s performance and longevity.

- Production Process Overview: An explanation of the entire assembly line, from cell stringing to final testing, helps each team member understand how their role fits into the larger operation.

This phase ensures every employee, regardless of background, shares the same technical vocabulary and commitment to quality before handling any equipment.

Phase 2: Specialized, Hands-On Machine Training (2-3 Weeks)

With the theoretical foundation in place, training moves to the production floor. The team is divided into small groups, each assigned to a specific station within the solar factory layout. Under the direct supervision of an experienced engineer, trainees learn to operate the solar panel manufacturing machines specific to their role.

Training is methodical and repetitive, focusing on:

- Machine Operation: Learning the correct procedures for starting, operating, and stopping the machinery.

- Material Handling: Practicing the precise and careful handling of delicate components like solar cells and glass.

- Process Adherence: Executing each task exactly as specified in the work instructions to ensure consistency.

- First-Level Troubleshooting: Identifying common issues and understanding when to escalate a problem to a supervisor.

This hands-on phase is crucial for building muscle memory and confidence. The goal is not just to teach a task but to instill a deep understanding of the process and the importance of precision.

Phase 3: On-the-Job Mentorship and Ramp-Up (1-2 Weeks)

In the final phase, the assembly line starts running test modules under close supervision. This period allows the team to integrate their skills and learn to work together as a cohesive unit, with production speed gradually increasing as they become more proficient.

This phase is also where the “Train the Trainer” model is implemented. Supervisors identify individuals who demonstrate strong technical aptitude, leadership potential, and communication skills. These candidates receive additional mentoring to become the facility’s future trainers and team leaders, ensuring the operation’s long-term self-sufficiency.

Integrating Quality Control into the Training Process

Quality control is not a separate department; it’s a mindset embedded throughout the training program. From day one, trainees learn that they are responsible for the quality of their own work.

This mindset is reinforced through hands-on practice at key inspection points:

- Visual Inspection: Trainees learn to identify defects like microcracks, scratches, or soldering imperfections.

- Electroluminescence (EL) Testing: Operators are trained to use EL testers to see invisible defects within the modules and ensure internal integrity.

- Sun Simulation: Technicians learn to operate the sun simulator (flasher) to test the module’s electrical output and verify that it meets performance specifications.

By empowering the local team with the tools and knowledge to manage quality, the facility can consistently produce modules that meet international standards.

A Sustainable Model: From Trainee to Team Leader

The ultimate goal of this training blueprint extends beyond starting production. The “Train the Trainer” model creates a sustainable system for continuous improvement and knowledge transfer. Local team leaders become the primary drivers of training for new hires and ongoing skill development.

This approach offers several strategic advantages:

- Reduces Long-Term Reliance: It minimizes the need for continuous oversight from expatriate experts.

- Builds Local Leadership: It creates clear career progression paths, increasing employee motivation and retention.

- Ensures Consistency: It codifies best practices and ensures that quality standards are maintained as the team grows.

By investing in a structured training program, a business not only builds a factory but also develops a skilled, self-reliant, and motivated local workforce—the most valuable asset for any long-term manufacturing operation.

Frequently Asked Questions (FAQ)

What qualifications should be sought in initial hires for a new solar assembly plant?

For entry-level production roles, the focus should be less on prior technical experience and more on attitude and aptitude. Look for attributes like good hand-eye coordination, attention to detail, a demonstrated ability to follow instructions, and a positive willingness to learn. A background in fields requiring dexterity, such as textiles or electronics repair, can be advantageous but is not a prerequisite.

How long does it typically take for a newly trained team to reach full production capacity?

After the initial 4–6 week training program, a new team usually requires a ramp-up period of 3–6 months to reach the target production output and efficiency. This timeline can vary depending on the complexity of the module technology and the level of automation on the line.

What is the ongoing role of expatriate experts after the initial training?

Initially, expatriate engineers lead the training and oversee the production ramp-up. Their role then transitions to supporting and mentoring the newly appointed local team leaders and trainers. They remain available for advanced troubleshooting and guidance on process optimization, gradually phasing out as the local team becomes fully self-sufficient.

Is this training model applicable in regions outside of Eritrea?

Yes, absolutely. The three-phase principle—Foundational, Specialized, and On-the-Job Mentorship—is a universally applicable framework for building a skilled manufacturing workforce in any emerging market where a specific industrial skill set is not yet widely available. It has been successfully implemented in various countries across Africa, the Middle East, and Asia.