An investor evaluating locations for a new solar module factory might instinctively look to regions with low labor costs or year-round sunshine. The prospect of establishing such a facility in a high-cost Nordic country like Finland can, therefore, seem counterintuitive.

This perspective, however, overlooks the strategic advantages of a stable, high-tech economy with direct access to the European market. A successful venture here depends not on competing with low-cost production, but on a financial model built around efficiency, quality, and long-term value.

This analysis breaks down the primary financial considerations—Capital Expenditures (CAPEX) and Operational Expenditures (OPEX)—for entrepreneurs planning a solar module factory in Finland. We explore how to account for local factors like skilled labor, energy prices, and climate to build a realistic and resilient business plan.

Understanding Capital Expenditures (CAPEX) in the Finnish Context

Capital expenditures are the significant, one-time investments required to establish the factory before production can begin. While the core machinery is universal, the Finnish environment introduces specific variables that must be factored into the initial budget.

Machinery and Production Line Equipment

The heart of the factory is its production line. A typical semi-automated line with an annual capacity of 20-50 MW requires several key pieces of equipment. The total investment for machinery can range from 3 million to 7 million EUR, influenced by the level of automation and the equipment’s country of origin.

Key equipment includes:

- Cell Stringer: Automates the process of soldering solar cells together into strings.

- Layup Station: Assembles the module’s various layers (glass, EVA, cells, backsheet).

- Laminator: Fuses the layers together under heat and vacuum to create a durable module.

- Framing Machine: Attaches the aluminum frame to the laminate.

- Sun Simulator / IV Tester: Tests the finished module’s performance under standard conditions.

A crucial early decision is whether to source a complete turnkey factory setup or procure individual machines. A turnkey solution often streamlines integration and shortens commissioning time, offering a significant advantage for managing project timelines.

Building and Infrastructure: Adapting to the Nordic Climate

The factory building itself is a critical CAPEX component with unique requirements in Finland. Unlike facilities in warmer climates, a Finnish factory must be engineered for extreme cold, heavy snow loads, and energy efficiency.

- Building Size: A 20–50 MW facility typically requires a floor space of 2,500 to 4,000 square meters to accommodate the production line, raw materials warehousing, and finished goods storage.

- Insulation and HVAC: Superior wall and roof insulation is not an optional upgrade; it is a fundamental requirement for managing heating costs during long, cold winters. This increases initial construction costs by 15-25% compared to a standard industrial building in a temperate zone, but it directly lowers long-term operational expenses.

- Foundation and Structure: The building must be designed to withstand heavy snow loads, adding to structural engineering and material costs.

Initial Setup, Certifications, and Logistics

Beyond the physical assets, the initial budget must account for several other one-time costs:

- Installation & Commissioning: This includes the cost of engineers, often from the machine supplier, to install, calibrate, and ramp up the production line.

- Initial Raw Material Stock: A two- to three-month supply of solar cells, glass, aluminum frames, and other components is necessary for a smooth production start.

- Certifications: Achieving IEC and other necessary certifications is a mandatory step for selling modules in the European market. The solar module certification process involves third-party testing and factory audits, representing a significant upfront cost.

Analyzing Operational Expenditures (OPEX) for a Finnish Factory

Operational expenditures are the recurring costs of running the factory. In a high-cost environment like Finland, accurately forecasting and managing OPEX is key to long-term profitability.

Labor Costs: The Skill vs. Cost Equation

Finland’s high wages are a primary concern for any manufacturing venture. According to Eurostat data, Finnish industrial labor costs are substantially higher than in many other manufacturing hubs.

However, a sound financial model reframes this from a liability to a strategic asset. The higher cost corresponds to a highly educated, skilled, and efficient workforce. This translates into:

- Higher Productivity: Fewer employees are often needed per MW of output compared to low-cost regions, especially with well-designed automation.

- Lower Training Costs: The technical proficiency of the local workforce reduces the time and expense of training on complex machinery.

- Quality and Consistency: A skilled team is more likely to maintain high production quality, reducing defect rates and warranty claims.

For a 50 MW factory, a typical workforce might consist of 25–35 employees, including operators, technicians, and administrative staff.

High Industrial Energy Prices

Finland’s industrial electricity prices are a significant OPEX factor. The manufacturing process, particularly the lamination and cell stringing stages, is energy-intensive.

A forward-thinking business plan should include strategies to mitigate this cost:

- On-Site Solar Generation: Installing a rooftop or ground-mounted solar PV system can offset a portion of the factory’s electricity consumption.

- Power Purchase Agreements (PPAs): Negotiating long-term PPAs with energy providers can secure predictable and often lower electricity rates.

- Energy-Efficient Machinery: Selecting a list of solar panel manufacturing machines with low energy consumption during the procurement phase can yield substantial savings over the factory’s lifetime.

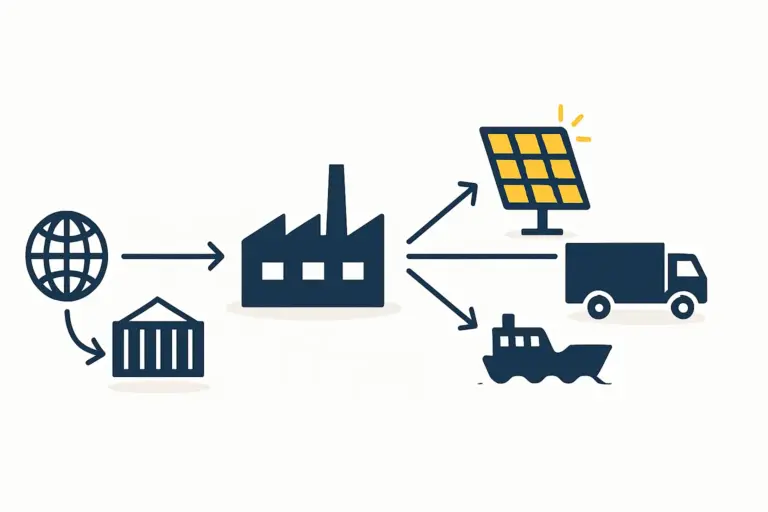

Raw Materials and Logistics

While the factory is located in Europe, many core components like solar cells are predominantly sourced from Asia. The financial model must account for shipping costs, import duties, and potential supply chain disruptions.

Finland’s location, however, also offers logistical advantages:

- Proximity to European Markets: Reduced shipping costs and faster delivery times to customers in the Nordic region, the Baltics, and Northern Europe.

- Local Sourcing Potential: Sourcing bulky materials like glass and aluminum frames from European suppliers can reduce transportation costs and lead times.

Taxes and Administration

Finland has a competitive corporate tax rate (currently around 20%), which is favorable compared to many other Western European nations. Administrative costs, insurance, and maintenance for the facility and machinery must also be included in the monthly operational budget.

Summary: A Viable Model for a High-Value Location

The financial model for a solar factory in Finland is fundamentally different from one in an emerging market. It is not based on minimizing absolute cost, but on maximizing value through efficiency, quality, and strategic location. Higher CAPEX in building infrastructure leads to lower OPEX in energy, while high labor costs are balanced by greater productivity and automation.

An investor who understands these dynamics can build a compelling business case for manufacturing high-quality solar modules in a stable, technologically advanced European nation.

Frequently Asked Questions (FAQ)

-

What is a realistic ROI timeline for a solar factory in Finland?

The return on investment (ROI) depends heavily on factors like the level of automation, operational efficiency, and the prevailing market price for solar modules. Generally, with a well-executed business plan, a payback period of 5-8 years is a reasonable target. -

Are government incentives available for setting up a factory in Finland?

Finland, like many EU countries, may offer investment grants, tax incentives, or support for projects that contribute to green technology and local employment. It is advisable to consult with regional development agencies like Business Finland to explore available programs. -

How does automation impact the financial model in a high-wage country?

Automation is crucial. Investing more in automated solar panel manufacturing machines during the CAPEX phase directly reduces the number of operators required, lowering long-term OPEX. This makes the business model more resilient to wage inflation and improves production consistency. -

Is it better to source machinery from European or Asian suppliers?

European machinery often comes with a higher price tag but may offer superior automation, build quality, and local service support, while Asian machinery is typically more cost-effective. The final decision depends on the overall budget, the desired level of automation, and the long-term maintenance strategy. -

How long does it take to establish a solar factory from planning to production?

Based on experience from turnkey projects, a realistic timeline is 10–14 months. This includes detailed planning, securing financing, building construction or renovation, machinery procurement and installation, and workforce training.