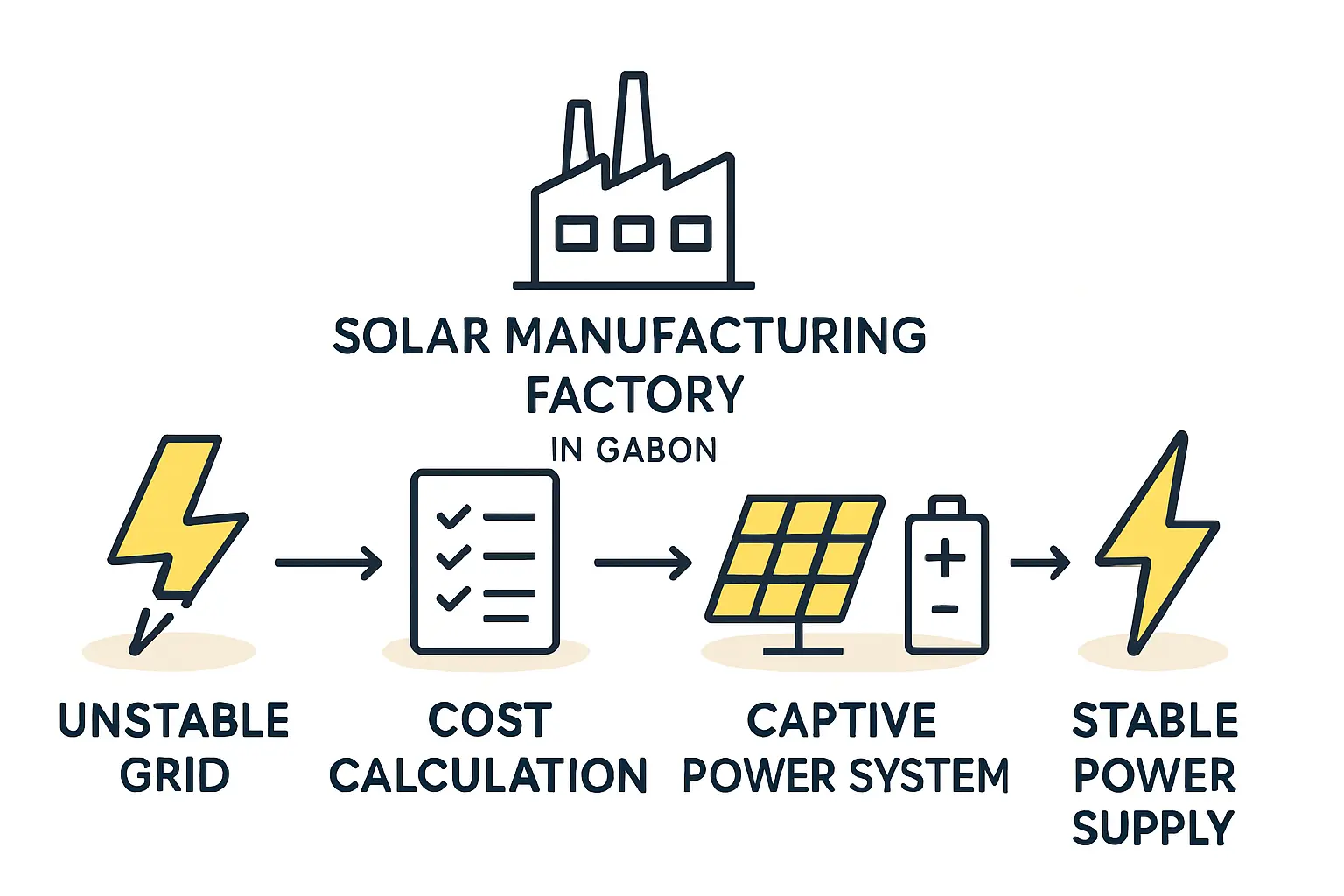

An investor envisions a state-of-the-art solar module factory. The production line has been specified, the staff is ready, and market demand is clear. Yet, on a critical production day, the entire operation halts. The cause is not a mechanical failure or a supply chain issue, but something more fundamental: an interruption in the national power supply. For any industrial venture in an emerging market, this scenario is a significant, and often underestimated, operational risk.

This article assesses Gabon’s national power infrastructure and its direct implications for a solar manufacturing enterprise. We examine grid stability, energy costs, and the compelling business case for integrating a captive power solution to ensure the operational continuity vital for success.

Understanding Gabon’s National Power Landscape

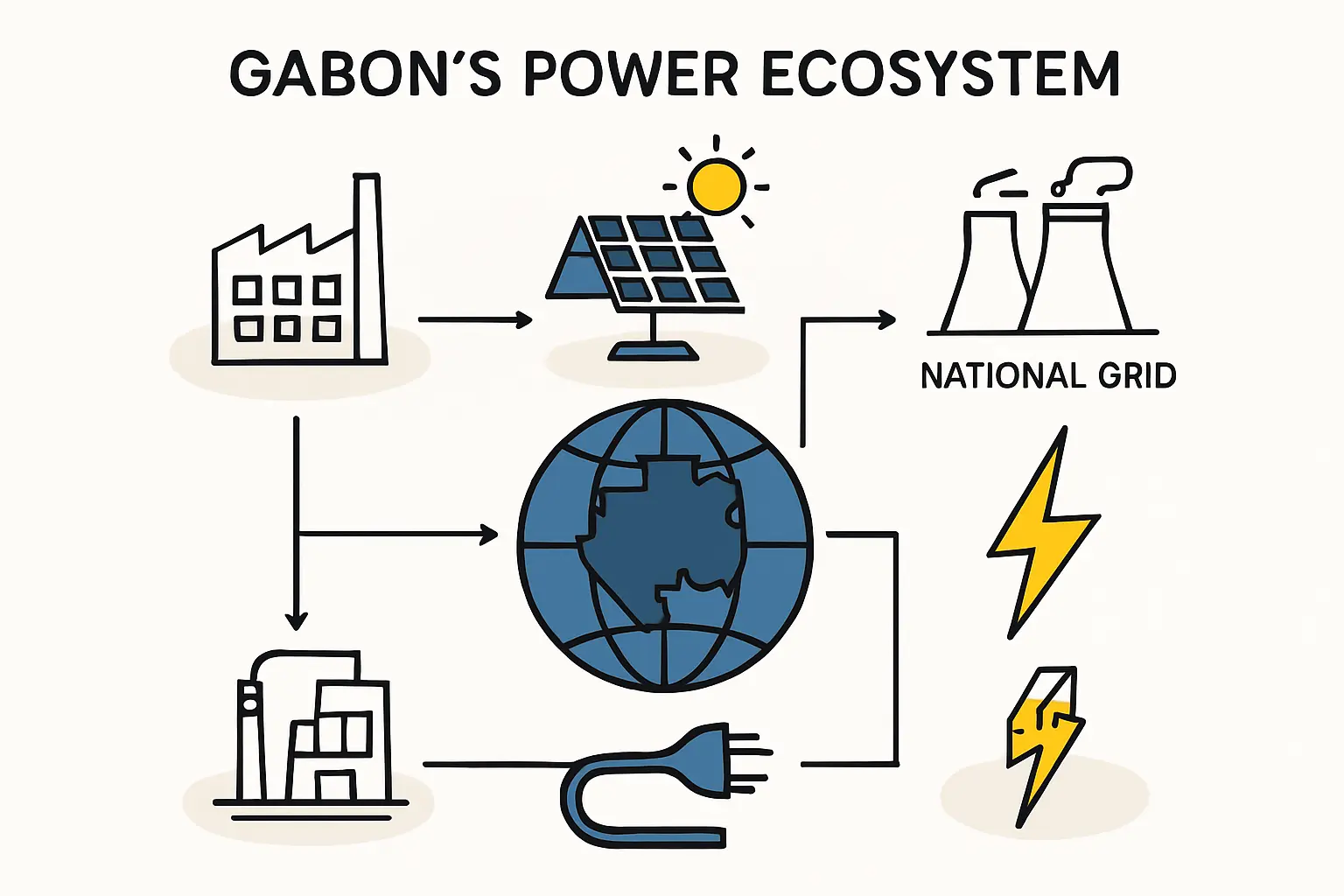

Gabon’s electricity sector, managed primarily by the Société d’Energie et d’Eau du Gabon (SEEG), has a distinct geographical and technical structure. The country does not have a single, unified national grid. Instead, it operates two main interconnected networks:

- The Libreville Interconnected Network (RIC): Serving the capital city and its surrounding areas.

- The Port-Gentil Interconnected Network (RII): Serving the country’s economic hub.

Beyond these networks, numerous isolated thermal power plants supply electricity to other parts of the country.

The nation’s power generation comes predominantly from two sources: hydropower, which accounts for approximately 60% of the mix, and thermal power plants (gas-fired), making up the remaining 40%. While this portfolio leverages Gabon’s significant water resources, the infrastructure that delivers this power to industrial users faces considerable challenges. The vast, dense rainforests covering much of the country make building and maintaining long-distance transmission lines a complex and costly undertaking.

The Core Challenge: Grid Reliability and Its Business Impact

For a precision manufacturing process like solar module production, a stable and uninterrupted power supply is not a luxury—it is a prerequisite. For an industrial investor in Gabon, the primary challenge is the reliability of the existing grid infrastructure.

Analysis of the grid reveals several key areas of concern:

-

High Transmission and Distribution (T&D) Losses: Approximately 20% of the electricity generated is lost before it reaches the end-user. This high figure points to aging and inefficient infrastructure, suggesting systemic weaknesses that can contribute to instability.

-

Infrastructure Deficiencies: Decades of underinvestment have resulted in an aging grid that is vulnerable to technical failures and environmental factors like severe weather. National electricity access stands at around 90%, but this figure masks a disparity between urban centers (over 95%) and rural areas (below 50%), highlighting the network’s concentration and limitations.

-

Generation vs. Demand: While installed capacity technically meets current peak demand, there is little reserve margin. Any unexpected shutdown of a major power plant or a sudden spike in demand can strain the network, leading to brownouts or blackouts.

For a solar module factory, the business impact of these issues is direct and severe. Unscheduled downtime leads to immediate production losses. Voltage fluctuations can damage sensitive and expensive equipment, such as cell stringers and laminators, resulting in costly repairs and extended operational pauses.

Analyzing the Financial Equation: Energy Costs in Gabon

The cost of electricity is a significant operational expense for any manufacturing plant. In Gabon, the tariff for industrial consumers is approximately $0.18 USD per kilowatt-hour (kWh). While this rate is a critical input for any financial model, a deeper analysis shows that the cost of unreliability can far exceed the direct cost of energy consumption.

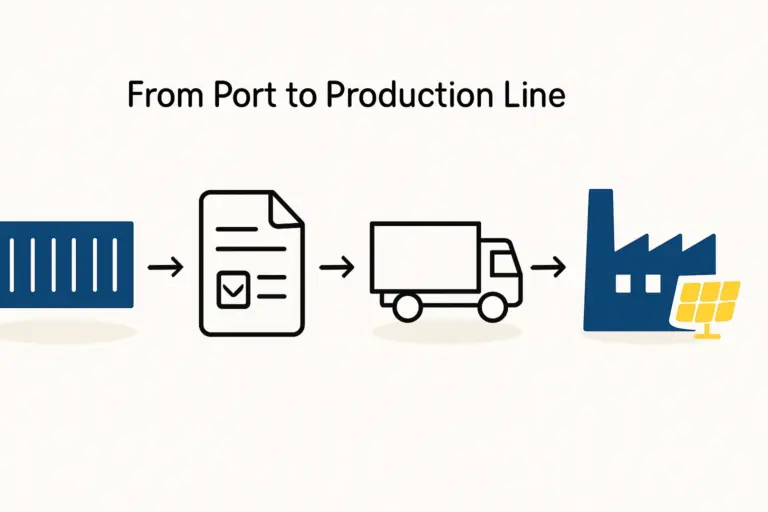

A factory’s financial projections must account not only for the stated tariff but also for the hidden costs of grid instability. These include lost revenue from production stoppages, expedited shipping fees to meet delayed orders, and potential penalties for failing to meet contractual obligations. The Gabonese government, through initiatives like the Gabon Power Expansion and Performance Improvement Project (GPEP), is actively working to improve the sector and attract private investment. However, these are long-term reforms, and investors planning operations in the near term must build a strategy based on current realities. Planning the [Link: /building-requirements-for-a-solar-factory | anchor: factory’s infrastructure] must include an energy solution that mitigates these risks from day one.

The Strategic Solution: Captive Power for Operational Resilience

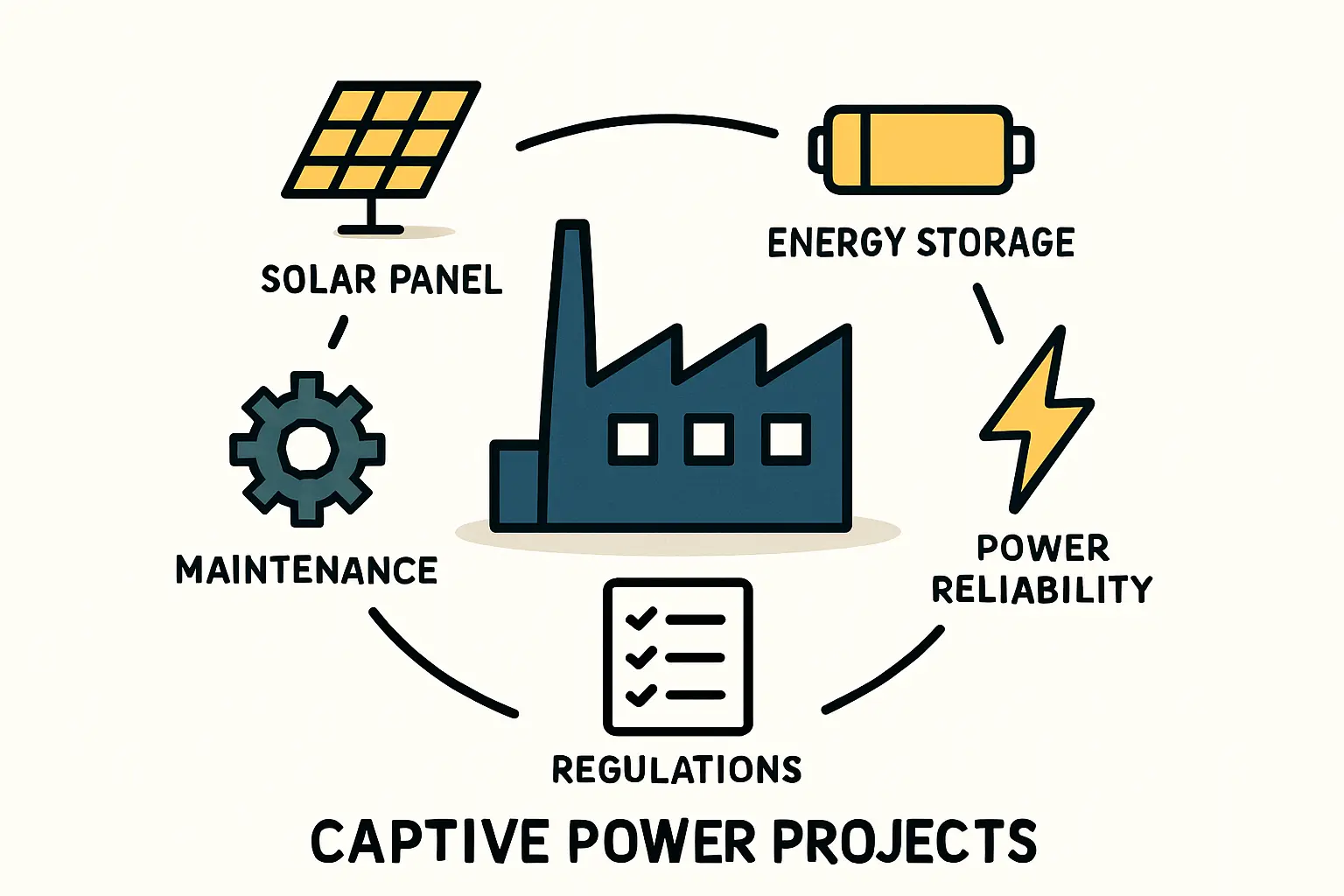

Given the instability of the national grid, relying on it solely for power is a high-risk strategy. The most prudent approach is to develop a captive, or self-contained, power system designed for maximum operational resilience. This is not merely a backup generator but an integrated hybrid system.

A typical hybrid power solution for a solar factory in Gabon would include:

-

Grid Connection: Used as the primary and most economical power source when it is stable and available.

-

Rooftop Solar PV System: The factory’s own solar array generates clean electricity during the day, directly offsetting grid consumption and lowering energy bills. This also sends a powerful sustainability message.

-

Battery Energy Storage System (BESS): This system stores excess solar energy and provides instantaneous, seamless power the moment a grid failure is detected, ensuring that critical machinery continues to operate without interruption.

-

Diesel or Gas Generator: Serves as the ultimate backup, capable of powering the entire facility during prolonged grid outages or periods of low solar generation, such as at night or during extended cloudy weather.

This hybrid model transforms energy from a potential liability into a controlled asset. The initial capital expenditure for such a system should be viewed as an insurance policy against catastrophic production losses. For entrepreneurs embarking on the journey of [Link: /how-to-start-a-solar-panel-manufacturing-business | anchor: solar panel manufacturing], integrating a robust power strategy early is critical for long-term success.

Frequently Asked Questions (FAQ)

What is the first step in assessing my factory’s power needs?

A detailed energy load analysis is the first step. It determines the precise power requirements of your production line and facility by calculating the consumption of each machine and ancillary system to establish peak load and average daily consumption. This analysis is a core component of a comprehensive [Link: /solar-factory-feasibility-study | anchor: feasibility study].

Can a solar factory rely solely on its own solar power system?

Operating a 24/7 manufacturing facility solely on solar power is technically possible but generally not economically viable. It would require an oversized solar array and a very large battery storage system to cover nighttime operations and multiple days of inclement weather. A hybrid approach that leverages the grid when available is the most cost-effective and reliable solution.

How does Gabon’s climate affect a captive solar installation?

Gabon’s equatorial location provides high and consistent solar irradiation, which is a major advantage for a solar PV installation. However, the climate also includes a significant rainy season with heavy cloud cover. The captive power system must be engineered to account for this seasonality, reinforcing the need for battery storage and a reliable generator backup.

Are there government incentives in Gabon for captive power generation?

The policy landscape for renewable energy and captive power is evolving as part of Gabon’s broader economic strategy. Investors should conduct thorough due diligence on current regulations, potential tax incentives, or streamlined permitting processes for industrial users who invest in their own power generation, particularly if it incorporates renewables.

Conclusion: Building a Resilient Foundation for Success

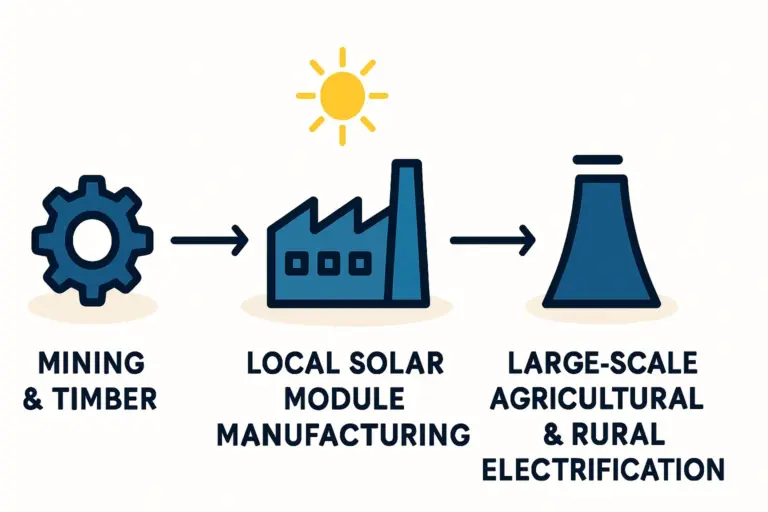

Gabon offers a compelling opportunity for a solar manufacturing presence, driven by regional demand and a strategic location. However, the success of such a venture depends on mitigating the known risks of its power infrastructure. The national grid should be viewed as one component of a broader energy strategy, not the entire solution.

By proactively investing in a hybrid captive power solution, an entrepreneur can insulate operations from grid instability, ensure production continuity, and maintain control over one of the most critical inputs of the manufacturing process. Based on experience from J.v.G. turnkey projects, addressing the power strategy early in the planning phase is one of the most effective ways to prevent costly delays and secure a project’s long-term profitability. For any serious investor, a robust business plan that accounts for these infrastructural realities is an essential foundation.