Gabon’s commitment to renewable energy and its abundant sunshine create a significant opportunity for investors and entrepreneurs. The potential for solar power is immense, but the very climate that provides this resource—characterized by high humidity, intense ultraviolet (UV) radiation, and high ambient temperatures—poses a severe threat to the longevity and performance of standard solar photovoltaic (PV) modules.

For any business professional planning to enter this market, understanding that not all solar modules are created equal is the key to a successful long-term investment. A module that performs well for decades in a dry, temperate climate may fail in just a few years in an equatorial one. This guide explores the specific technical requirements for durable, high-performance solar modules engineered to thrive in Gabon’s unique environment.

Understanding the Environmental Stressors in Gabon

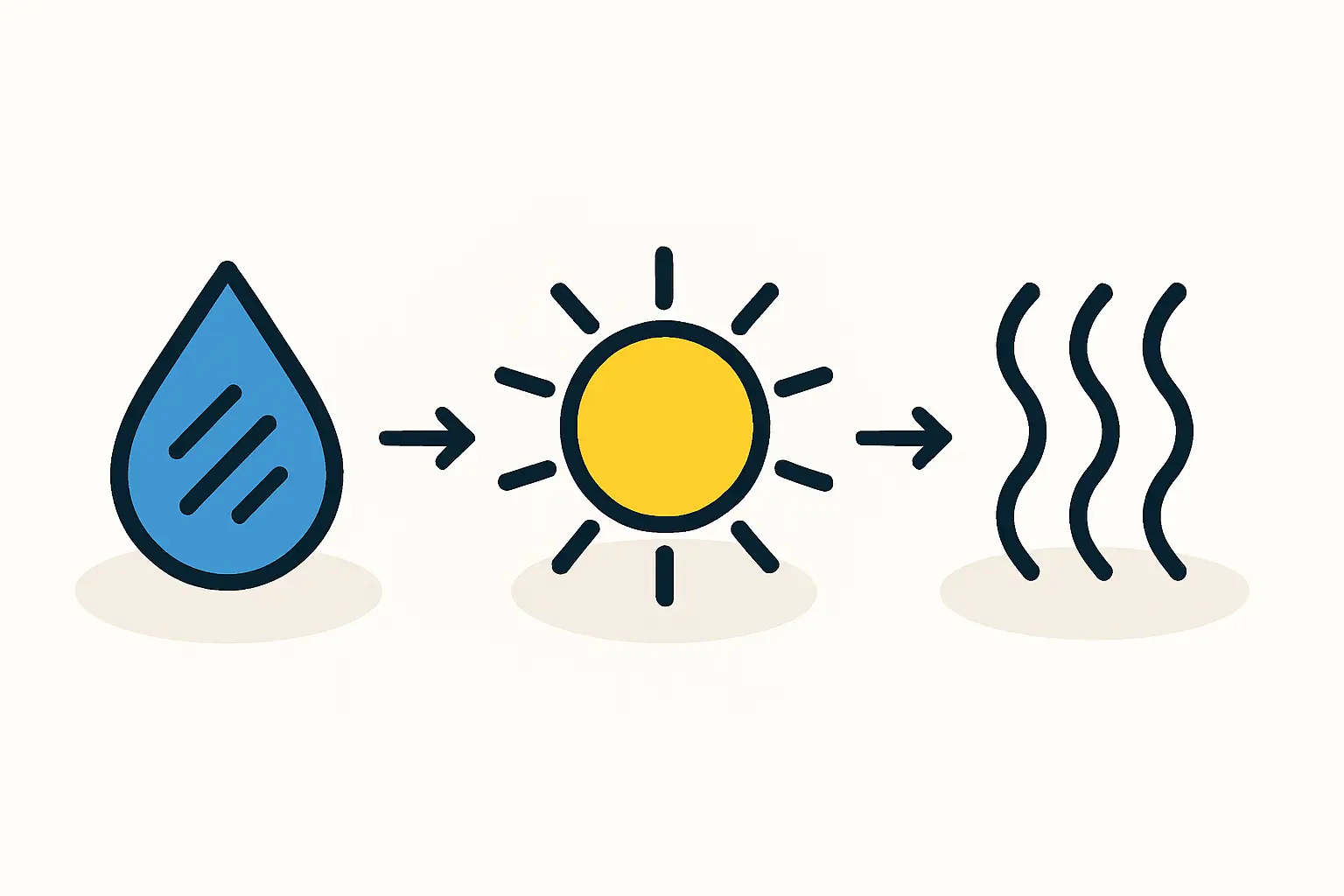

The combination of constant high humidity and strong, year-round solar irradiance creates an aggressive environment for any industrial equipment, and solar modules are no exception. This combination accelerates material degradation, significantly reducing a module’s power output and operational lifespan.

Consider the effect of leaving a standard vehicle parked in a coastal rainforest for several years. The humidity would lead to rust and electrical faults, while the intense sun would cause paint to fade and plastics to become brittle. A solar module faces a similar, constant battle against these elements.

Key environmental challenges in Gabon include:

-

High Humidity: Averages often exceed 80%, creating a moisture-rich atmosphere. This moisture can penetrate a module’s protective layers, leading to corrosion and electrical issues like Potential Induced Degradation (PID), where voltage differences cause power leakage and a rapid drop in performance.

-

High UV Irradiance: The equatorial sun emits intense UV radiation, which can break down the polymers used in a module’s construction. This leads to discoloration (yellowing), brittleness, and delamination.

-

Coastal Salt Mist: For projects near Gabon’s extensive coastline, airborne salt particles can accelerate the corrosion of metal components like the module frame and electrical contacts.

These factors make material selection critical to a solar project’s financial viability.

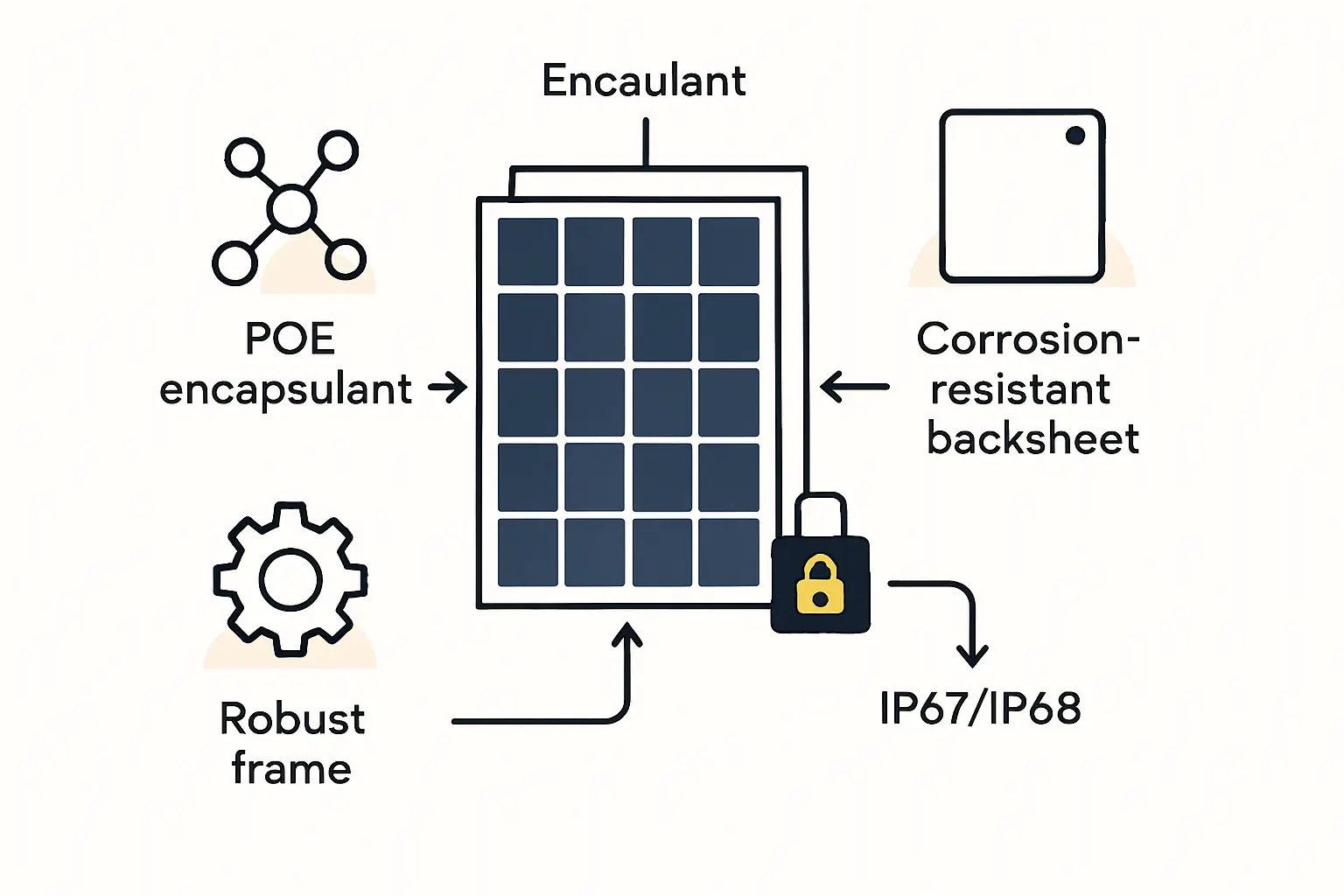

The Anatomy of a Solar Module: Key Components Under Threat

Building a durable module starts with understanding its basic structure. A solar module is a laminated sandwich of several critical layers, each with a specific function.

The two layers most vulnerable to Gabon’s climate are the backsheet and the encapsulant. These components serve as the primary defense for the delicate solar cells against the elements.

Selecting a Resilient Backsheet: The First Line of Defense

The backsheet is the outermost rear layer of a standard solar module. Its primary roles are to provide electrical insulation and act as a barrier against moisture and UV radiation.

In many commodity-grade modules, the backsheet is made from PET (Polyethylene Terephthalate). While cost-effective, PET is susceptible to hydrolysis—a chemical breakdown caused by prolonged exposure to water and humidity. Over time, a PET backsheet in a humid climate can crack, allowing moisture to reach the solar cells and cause catastrophic failure.

Durable performance in Gabon requires superior materials:

-

PVDF (Polyvinylidene Fluoride): Often known by the trade name Kynar, this material offers excellent resistance to UV radiation and hydrolysis. A PVDF-based backsheet provides a much more stable and long-lasting barrier against moisture.

-

Co-extruded Polyolefin: This advanced backsheet construction offers exceptional moisture resistance and durability without relying on adhesives between layers, which can themselves be a point of failure.

Specifying a high-performance backsheet is essential for any module intended for long-term operation in a humid, high-irradiance environment.

The Critical Role of Encapsulant: Protecting the Solar Cells

The encapsulant is the transparent adhesive material that surrounds the solar cells, bonding the glass front to the backsheet. It cushions the cells and protects them from moisture, oxygen, and physical stress.

The industry standard for many years has been EVA (Ethylene Vinyl Acetate). However, under high heat, humidity, and UV exposure, standard EVA can degrade. This process, known as yellowing or browning, reduces the amount of light reaching the solar cells, thereby decreasing power output. The chemical breakdown of EVA also produces acetic acid, which can accelerate corrosion inside the module.

A far superior alternative for equatorial climates is POE (Polyolefin Elastomer). POE offers several key advantages:

-

Exceptional Moisture Resistance: Its water vapor transmission rate is significantly lower than that of EVA, providing better protection against humidity.

-

PID Resistance: POE’s high electrical resistivity makes it inherently resistant to Potential Induced Degradation, a critical advantage in humid regions.

-

UV Stability: It does not yellow or break down under UV exposure, ensuring long-term transparency and stable power output.

While POE has a higher initial material cost, its contribution to the module’s lifespan and performance makes it a wise investment for projects in climates like Gabon’s.

The Premier Solution: Glass-Glass Module Construction

For ultimate durability and moisture protection, the best technical solution is to replace the polymer backsheet entirely with a second sheet of glass. These Glass-Glass modules offer a virtually impermeable barrier against moisture.

Because glass is inorganic and extremely stable, it does not suffer from the same degradation that affects polymer backsheets. This construction provides the highest level of protection for the solar cells, leading to a longer service life and lower degradation rates, particularly in challenging climates. While the initial investment and module weight are higher, the long-term reliability often justifies the cost for critical, large-scale infrastructure projects.

Beyond Materials: The Importance of Manufacturing Process Control

Specifying premium materials like POE and PVDF is only the first step. The long-term performance of a module depends entirely on the quality and precision of the manufacturing process. A poorly calibrated lamination machine or incorrect process parameters can compromise the integrity of even the best materials.

This is why establishing a robust quality management system is essential when starting a solar module factory. The processes for lamination—including temperature, pressure, and cycle time—must be perfectly optimized for the specific materials being used.

Achieving international certifications like IEC 61215, which includes rigorous damp-heat and PID resistance tests, provides independent verification that a module is manufactured to withstand these harsh conditions. For new entrants, implementing a turnkey manufacturing line designed by experienced engineers can ensure these critical processes are correctly established from day one.

Frequently Asked Questions (FAQ)

Why can’t standard solar modules be used in Gabon?

Standard modules, often designed for temperate European or North American climates, use materials like PET backsheets and EVA encapsulants that degrade rapidly under the combined stress of high humidity and intense UV radiation found in equatorial regions. This can lead to premature failure and a poor return on investment.

Are modules designed for Gabon significantly more expensive?

Modules built with high-performance materials like POE encapsulants and PVDF backsheets have a higher upfront material cost. However, this cost should be evaluated against the module’s total lifetime energy production. The superior durability and lower degradation rate often result in a lower Levelized Cost of Energy (LCOE), making them a more profitable long-term investment.

What is the expected lifespan of a module with these specifications in an equatorial climate?

While standard modules might see significant degradation in 5–10 years, a module properly constructed with POE, a high-performance backsheet, or a Glass-Glass design is engineered to last for 25–30 years or more, with performance warranties to match.

How does a local manufacturer ensure these specifications are met?

A local manufacturer ensures quality by implementing a strict Quality Management System. This involves rigorous inspection of incoming materials to ensure they meet specifications, precise calibration and control of all manufacturing equipment (especially the laminator), and regular in-house testing (e.g., electroluminescence, wet-leakage tests) to validate the integrity of the finished modules.

Conclusion and Next Steps

For entrepreneurs and investors looking to capitalize on Gabon’s solar potential, success depends on a deep understanding of the local climate’s technical demands. Moving beyond standard, commodity-grade module specifications is not an option—it is a requirement for building a sustainable and profitable business.

By focusing on superior, climate-appropriate materials such as POE encapsulants, PVDF or polyolefin backsheets, and considering Glass-Glass construction, a manufacturer can produce PV modules that deliver reliable, long-term performance. This technical foresight is the foundation of a strong market reputation and a successful solar enterprise in the equatorial belt.