Imagine a state-of-the-art solar module production line, meticulously planned and installed. The machines are calibrated, the staff is trained, and the first batch of high-quality solar cells is moving through the automated stringer. Suddenly, the lights flicker and the facility falls silent. A power outage has halted production mid-cycle.

Far from a remote possibility, this scenario represents a critical business risk for entrepreneurs in many promising markets.

For a solar module factory, a consistent, high-quality power supply isn’t a luxury—it’s the lifeblood of the operation. This guide explains why energy stability is paramount and outlines practical strategies for building a resilient power infrastructure, particularly in regions like Ghana where grid challenges are a known factor.

The High Cost of Unstable Power in Manufacturing

The irony of producing renewable energy technology in a facility plagued by power interruptions is hard to miss. In markets facing grid challenges, such as Ghana’s well-documented ‘dumsor’ (frequent and unpredictable outages), the operational risks extend far beyond simple downtime.

Sensitive solar module manufacturing equipment—including laminators, stringers, and testers—requires a continuous, stable supply of electricity to function correctly. Grid instability can manifest in several damaging forms:

-

Production Halts: An unexpected shutdown can ruin materials mid-process. A single aborted cycle in a laminator, for instance, can result in the complete loss of an entire batch of modules—a loss amounting to thousands of dollars and hours of wasted production time.

-

Equipment Damage: Beyond simple outages, the voltage fluctuations and frequency variations common to an unstable grid can cause long-term damage to sophisticated electronic components, leading to expensive repairs and extended downtime.

-

Reduced Efficiency: Constant starts and stops disrupt the manufacturing rhythm, decrease throughput, and make it difficult to meet production targets and client deadlines.

These challenges are compounded by economic factors. As of 2023, industrial electricity tariffs in Ghana were approximately $0.14 to $0.20 per kWh. While these rates are viable for business, combining them with an unreliable supply creates a compelling case for establishing energy independence.

Building an Independent Power Supply: A Strategic Approach

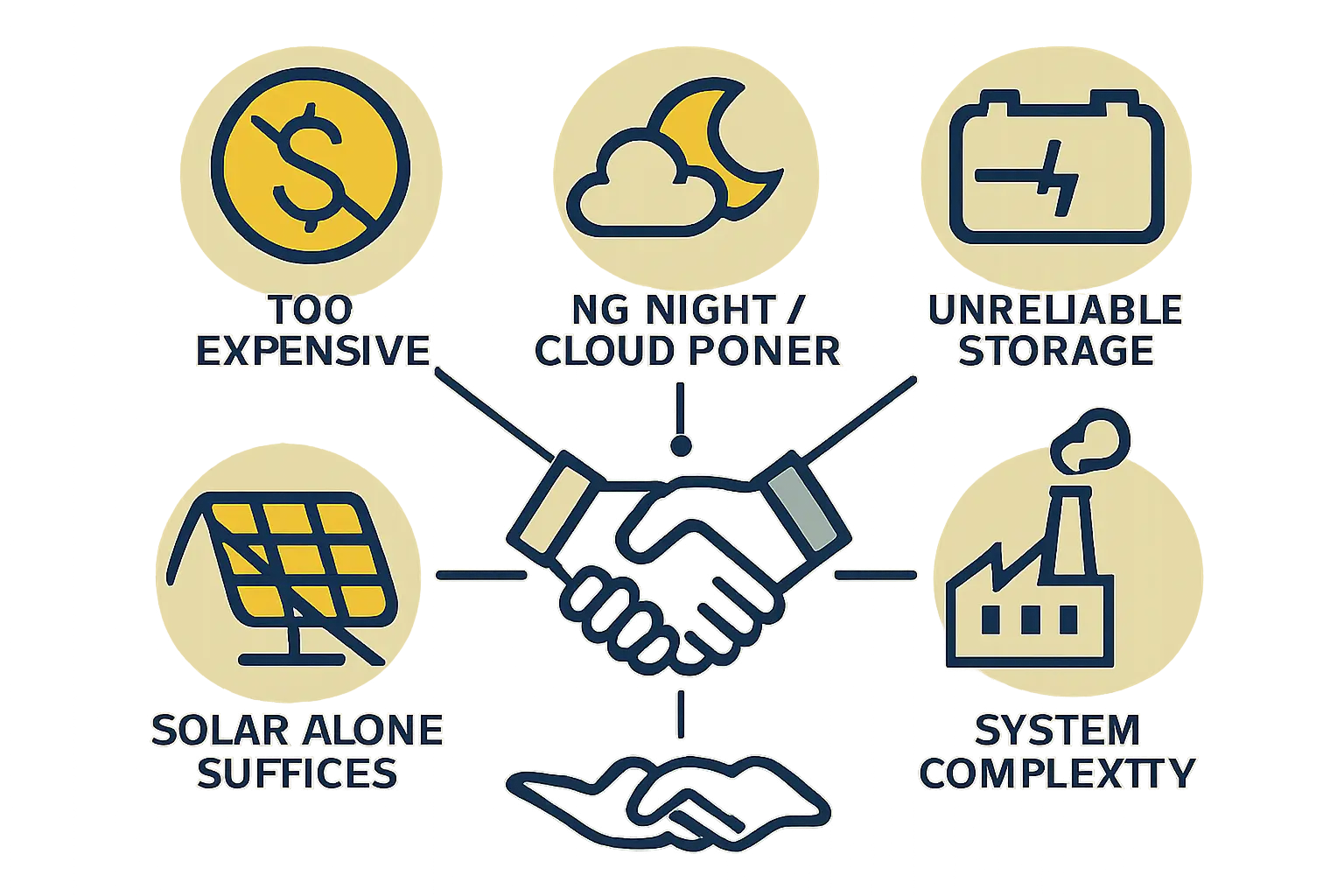

An unreliable grid shouldn’t be viewed as an insurmountable obstacle, but as a manageable engineering challenge. The solution lies in designing a hybrid power system that insulates the factory from external disruptions, typically involving a combination of on-site generation, energy storage, and intelligent power management.

The Core Solution: Hybrid Solar-Plus-Storage

A dedicated solar photovoltaic (PV) system combined with a Battery Energy Storage System (BESS) is the most logical and increasingly economical solution. Together, they create a private microgrid for the factory.

Here’s how the system works:

-

On-Site Generation: A commercial-scale solar array, typically installed on the factory roof or adjacent land, generates electricity during daylight hours. This directly powers the manufacturing line, significantly reducing reliance on the grid and lowering energy costs.

-

Energy Storage: The BESS captures excess solar energy generated during peak production hours. This stored power can then run the facility when solar generation is low, such as on cloudy days or overnight.

-

Uninterrupted Operation: In the event of a grid outage, the BESS instantly takes over, providing seamless power to critical machinery. An intelligent energy management system handles the transition, ensuring a smooth, instantaneous switch.

This hybrid model directly counters the high operational costs of traditional backup solutions. While diesel generators are a common fallback, their operating costs of $0.30 to $0.40 per kWh (including fuel and maintenance) make them an expensive primary backup. A solar-plus-storage system, after the initial investment, provides power at a much lower long-term cost.

The Role of Backup Generators and UPS

Even with a robust solar and battery system, a multi-layered approach to power security is advisable.

-

Backup Generators (Diesel/Gas): A generator remains a valuable component for ensuring absolute continuity during prolonged grid outages or periods of extended bad weather that could deplete battery reserves. It serves as the final line of defense, ensuring the plant can operate under virtually any condition.

-

Uninterruptible Power Supply (UPS): For the most sensitive electronics, such as servers and control systems, a UPS is essential. It provides instantaneous battery power to bridge the brief moment—often milliseconds—between the start of an outage and the activation of the main battery system or generator.

Integrating these elements is a core part of planning a turnkey solar panel production line. In turnkey projects managed by firms like J.v.G. Technology, establishing a reliable power supply strategy is a foundational step, designed and engineered right alongside the factory itself.

Investment and Long-Term Viability

Investing in an independent power system adds to the initial project cost. However, this should be viewed not as an expense, but as a strategic investment in operational stability and profitability. The ability to manufacture modules 24/7, regardless of grid conditions, provides a significant competitive advantage.

When business owners calculate the total investment for a new factory, factoring in a resilient power solution from the outset prevents far greater costs down the line from lost production, damaged equipment, and reputational harm. The return on this investment is realized through:

-

Reduced Electricity Bills: On-site solar generation drastically lowers reliance on utility-provided power.

-

Elimination of Downtime Costs: The system pays for itself by preventing costly production interruptions.

-

Predictable Operational Planning: Stable power allows for accurate production forecasting and reliable order fulfillment.

Frequently Asked Questions (FAQ)

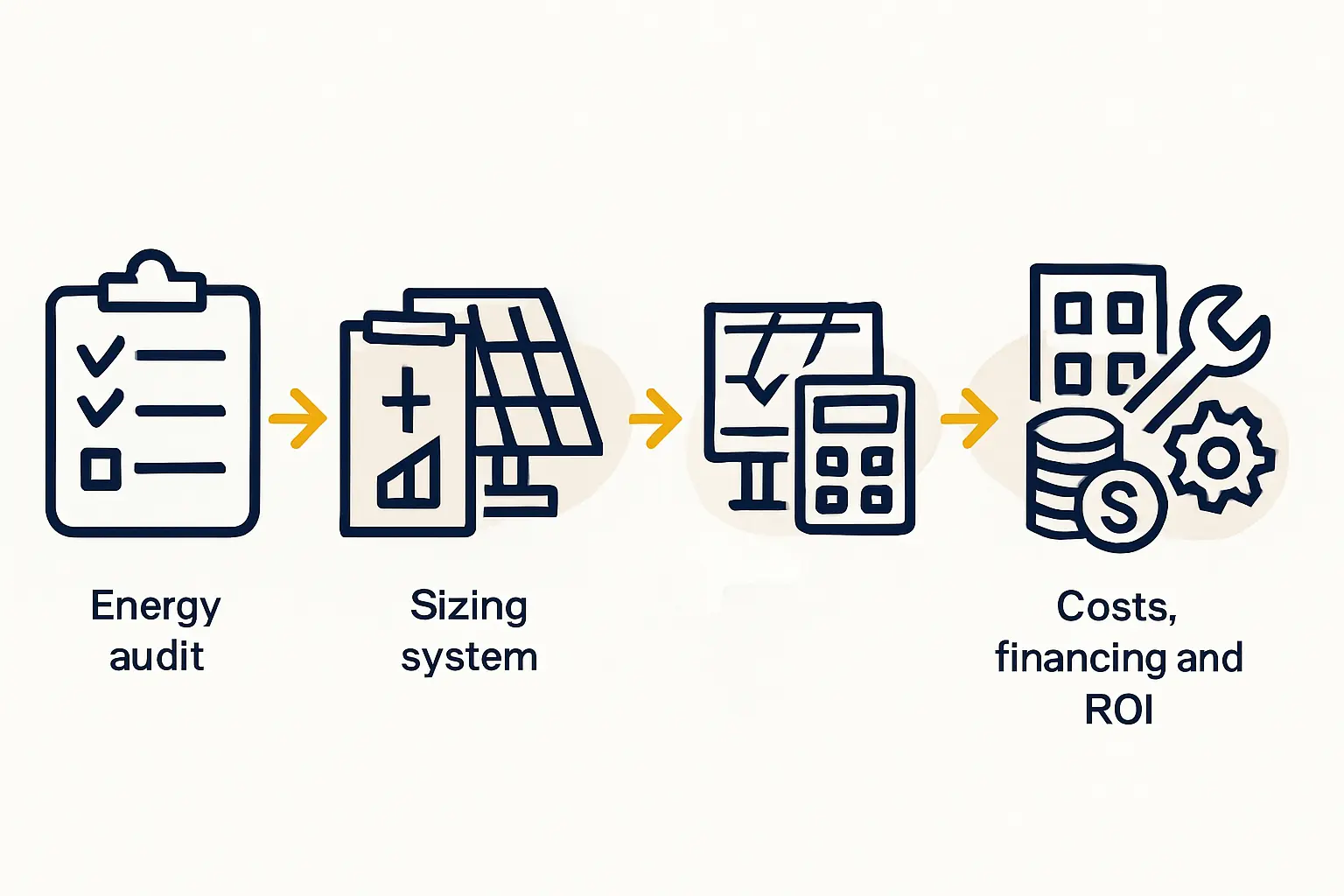

What size solar and battery system would a typical factory require?

The system size depends directly on the factory’s production capacity and energy consumption. For example, a facility with a 50 MW annual capacity might consume 1,500 to 2,000 MWh per year. This would typically require a solar PV system of approximately 1-1.5 MW and a BESS with several hours of storage, tailored to the specific operational schedule (e.g., one, two, or three shifts).

Is a diesel generator still necessary with a solar and battery system?

While not strictly required, a generator is highly recommended for maximum resilience. It provides a crucial layer of redundancy for worst-case scenarios, such as multi-day grid outages combined with poor weather, ensuring the plant remains operational under virtually any circumstance.

How does this affect the overall project budget?

A dedicated power infrastructure can represent a significant portion of the initial capital expenditure. However, its cost should be weighed against the financial risks of grid dependency. In many cases, financing options are available for renewable energy systems, and the long-term savings on electricity and avoided downtime create a strong business case for the investment.

Can the factory sell excess electricity back to the grid?

This depends entirely on local regulations and the utility’s policies on grid-tied generation and net metering or feed-in tariffs. In some jurisdictions, selling excess power can create an additional revenue stream, strengthening the project’s financial profile. This possibility should be investigated during the initial planning phase.

Ultimately, for any entrepreneur planning to enter the solar module manufacturing industry in a region with an unstable grid, securing an independent power supply is a foundational requirement for success. By integrating on-site solar generation, battery storage, and appropriate backup systems, a factory can achieve the energy resilience needed to operate continuously, efficiently, and profitably. This strategic foresight transforms a potential liability into a source of competitive strength.