For any entrepreneur considering a new market, the question of talent is paramount. In a technologically advanced industry like solar panel manufacturing, this question takes on even greater urgency. An investor might look at Ghana’s burgeoning renewable energy market and see immense potential, but also a significant challenge: how to build a highly skilled local team capable of operating a sophisticated production facility from the ground up.

The common assumption is that such an endeavor requires a large contingent of expatriate experts for the long term. However, a strategic approach to workforce development can not only mitigate this need but also create a more sustainable, cost-effective operation that is deeply integrated into the local economy.

This article outlines a practical, three-phase blueprint for recruiting, training, and retaining a world-class engineering team in Ghana, transforming local potential into operational excellence. This framework offers essential insights for anyone exploring how to start a solar panel factory in an emerging market.

Understanding the Ghanaian Context: Opportunity and Challenge

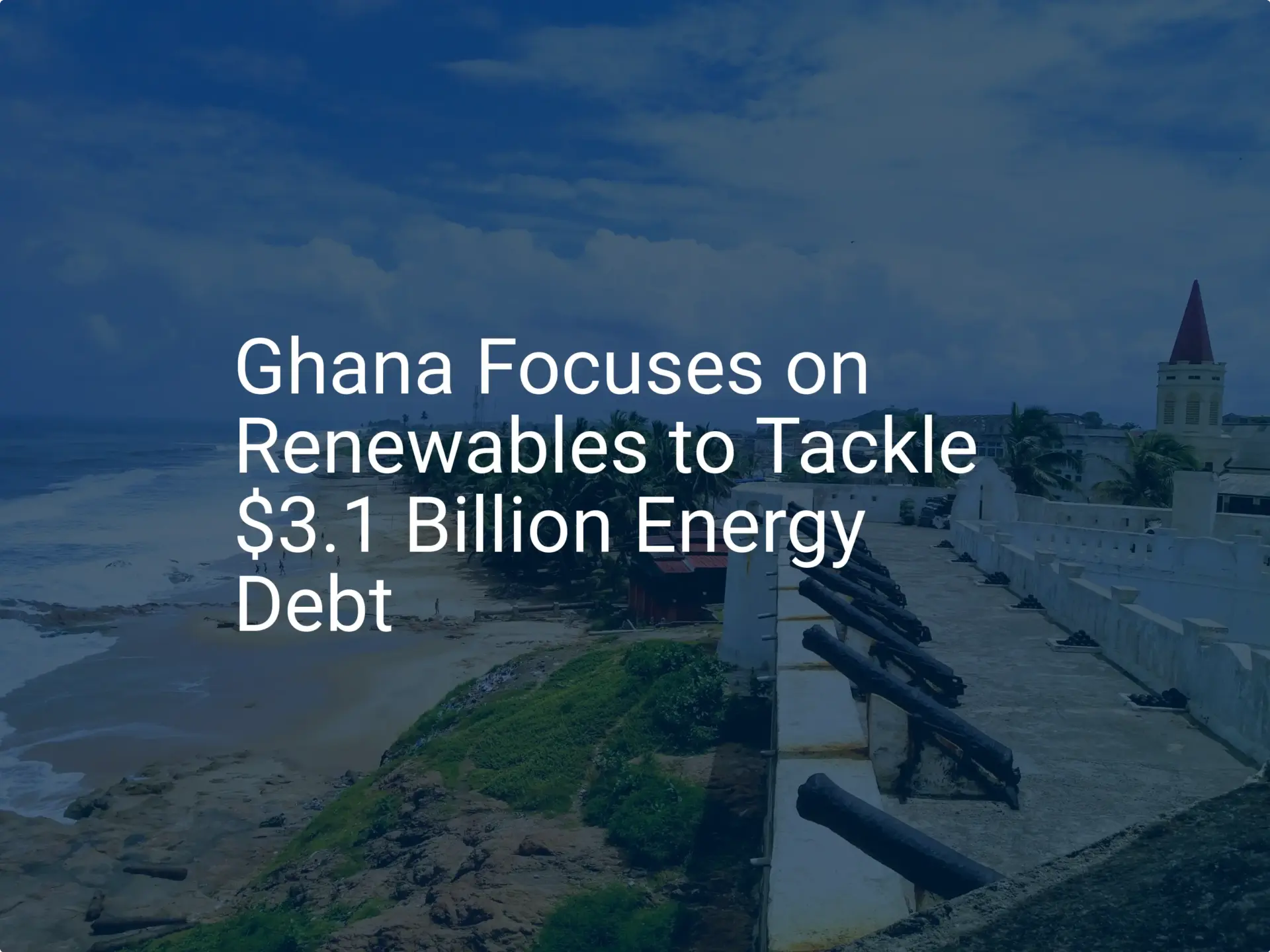

Ghana presents a compelling case for solar manufacturing. The government’s Renewable Energy Master Plan (REMP) aims for 10% of the energy mix to come from renewable sources by 2030. This ambition is fueled by practical necessity; persistent power shortages, locally known as ‘dumsor,’ have spurred public and commercial demand for reliable energy alternatives.

This opportunity, however, is not without its challenges. The primary obstacle noted by industry observers is the gap between the theoretical knowledge of university graduates and the practical skills required in a high-tech manufacturing environment.

At the same time, government policy actively encourages local investment in human capital. The Local Content and Local Participation Regulations (L.I. 2354) mandate significant involvement of Ghanaian citizens in the energy sector. This regulation transforms workforce development from a good business practice into a legal and operational imperative. The blueprint that follows addresses this requirement directly, offering a clear path to both compliance and competitive advantage.

Phase 1: Strategic Recruitment Through University Partnerships

The foundation of a strong workforce is built long before the first job advertisement is posted. Ghana’s educational institutions, such as the Kwame Nkrumah University of Science and Technology (KNUST) and various Technical Universities, produce a steady stream of engineering graduates. The challenge lies in identifying individuals with the right aptitude and bridging their academic knowledge with industry-specific skills.

Forging strategic partnerships with these universities is the most effective first step. These collaborations create a direct talent pipeline to the manufacturing facility.

Key components of a university partnership program include:

- Curriculum Co-Development: Working with faculty to introduce specialized modules on photovoltaic technology and modern manufacturing principles.

- Internship and Co-op Programs: Offering structured, paid internships that allow students to gain real-world experience within the factory setting, even before it is fully operational.

- Guest Lectures and Seminars: Sponsoring seminars led by industry experts to expose students to the practical realities and career opportunities in solar manufacturing.

- Early Talent Identification: Using these programs to identify high-potential candidates for full-time employment upon graduation, reducing recruitment time and costs.

This proactive approach ensures a consistent flow of pre-vetted, motivated junior engineers who are already familiar with the company’s culture and technical standards.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

Phase 2: The Skills Transfer Program – A Hands-On Approach

Once a core team of local engineers is recruited, the most critical phase begins: intensive skills transfer. Theoretical training alone is insufficient for a complex, process-driven operation. The most effective method is direct, hands-on mentorship, modeled on the apprenticeship principles that have defined German engineering excellence for generations. This approach, similar to the hands-on philosophy of the Thoma family who founded J.v.G. Technology, emphasizes learning by doing under expert guidance.

The program unfolds in stages on the factory floor:

- Foundation Training: Initial classroom sessions provide a comprehensive overview of the entire solar panel manufacturing process, from material science to quality assurance protocols. This ensures everyone shares a common technical vocabulary and understanding.

- On-the-Job Mentorship: A small team of experienced expatriate supervisors works directly alongside the new Ghanaian engineers on the turnkey solar manufacturing line. Each step, from operating the stringer to calibrating the laminator, is demonstrated, practiced, and perfected together. This side-by-side collaboration is the fastest way to build technical competence and confidence.

- The Train-the-Trainer Model: During the mentorship period, expatriate supervisors identify local engineers who demonstrate exceptional technical skill and leadership potential. These individuals receive advanced training to become the next generation of team leaders and internal trainers, ensuring these skills become self-sustaining within the local team.

Based on J.v.G.’s experience with turnkey projects, this direct mentorship model reduces the learning curve for complex machine operation by over 40% compared to traditional, classroom-only training programs.

Phase 3: Cultivating Operational Excellence and Long-Term Retention

With a competent team in place, the focus shifts from basic operation to achieving and maintaining world-class standards. This final phase embeds a culture of continuous improvement and creates clear pathways for career advancement to retain top talent.

Key initiatives include:

- Quality Management Systems: Implementing and certifying the operation under international standards like ISO 9001. This provides a clear framework for quality control and process optimization.

- Performance Metrics: Establishing clear Key Performance Indicators (KPIs) for production output, material yield, and equipment uptime. These metrics empower teams to take ownership of their performance.

- Career Development Paths: Defining clear criteria for promotion from junior engineer to senior engineer, shift supervisor, and, eventually, department manager. This structured progression shows employees a long-term future with the company.

By investing in their professional growth, the company not only improves operational efficiency but also builds a loyal and motivated workforce, significantly reducing the high costs associated with employee turnover.

Measuring Success: Key Performance Indicators for Workforce Development

The blueprint’s effectiveness can be measured with clear business metrics that demonstrate the return on investment in training and development.

- Time to Autonomy: The time required for a production shift to operate at target efficiency with minimal expatriate supervision. The goal is typically 12-18 months.

- Production Yield: The percentage of A-grade solar modules produced, aiming for industry benchmarks of 98.5% or higher.

- Employee Retention Rate: The percentage of the initial engineering cohort retained after two years. A rate above 85% indicates a successful program.

- Internal Promotion Rate: The percentage of supervisory and management roles filled by local Ghanaian staff within the first five years of operation.

Ultimately, the goal is not just to produce solar panels, but to build a self-reliant, high-performing organization. The final, most powerful indicator of success is a product that meets global quality standards, proudly bearing a ‘Made in Ghana’ label.

Frequently Asked Questions (FAQ)

How long does it typically take to train a local team for a solar factory?

A structured program begins with three to six months of intensive, hands-on training. Full operational autonomy, where local teams manage all shifts with minimal supervision, generally takes 12 to 18 months to achieve.

What are the most critical roles to hire first?

The initial core team should consist of process engineers to oversee the production flow, quality control technicians to ensure product standards, and maintenance supervisors, who are critical for maximizing equipment uptime.

Is it necessary to bring in expatriate supervisors for the long term?

Expatriate supervisors are essential during the initial skills transfer phase (Phase 2). However, the goal of the ‘Train-the-Trainer’ model is to systematically transfer their knowledge to local leaders, eventually making a long-term expatriate presence unnecessary.

How does this workforce development plan align with Ghana’s Local Content regulations?

This blueprint is designed specifically to meet and exceed the requirements of L.I. 2354. By actively recruiting from local universities, implementing a comprehensive skills transfer program, and creating clear paths to management for Ghanaian citizens, it provides a documented, good-faith effort to build local capacity and participation.