Picture this: Your new solar module manufacturing facility is ready for its first major production run. The state-of-the-art stringer and laminator are calibrated, materials are in place, and your team is prepared. Suddenly, the lights flicker and the entire production line grinds to a halt. The culprit isn’t an internal malfunction but a power outage from the local grid—a common occurrence in many rapidly developing regions. The irony is unmistakable: a factory designed to advance clean energy is itself stalled by energy instability.

For entrepreneurs planning to establish a solar factory in a market like Guyana, this scenario is more than a hypothetical risk; it’s a critical business challenge that demands strategic foresight. While Guyana’s economy is expanding, its energy infrastructure presents unique hurdles that must be addressed from the earliest stages of planning.

The Critical Role of Stable Power in Solar Module Manufacturing

A solar panel factory is unlike a typical assembly plant where production can be paused and restarted with minimal consequence. Several core processes are highly sensitive to power interruptions.

-

Lamination: This irreversible, heat-intensive process is where the solar cell assembly is encapsulated. An unexpected power loss mid-cycle can damage the laminator’s heating plates and render an entire batch of modules unusable, leading to significant material waste and financial loss.

-

Cell Soldering (Stringing): Automated stringers use precise temperature controls to solder solar cells together. A sudden shutdown can cause inconsistent connections, leading to lower module efficiency and higher rejection rates during quality control.

-

Testing and Flashing: The final quality assurance step uses a solar simulator (flasher) to measure a module’s power output. Unstable voltage can affect the accuracy of these measurements, compromising the final product’s certification and market value.

Downtime in such a capital-intensive facility directly impacts profitability, delaying order fulfillment and damaging the business’s reputation for reliability.

Understanding Guyana’s Energy Landscape

Operating successfully in Guyana requires a clear understanding of the local context. The national grid, primarily run by Guyana Power and Light (GPL), has historically faced challenges. The country has long relied on imported heavy fuel oil for power generation, making electricity costs susceptible to global price volatility.

Grid reliability is also a significant concern. Reports from previous years, for instance, have highlighted frequent power disruptions. This instability poses a substantial operational risk for any industrial enterprise, especially one with sensitive manufacturing processes.

However, the Guyanese government is actively pursuing a transition towards renewable energy under its Low Carbon Development Strategy (LCDS) 2030. This creates a powerful alignment for new solar ventures, but the transition period means businesses must plan for today’s infrastructure realities.

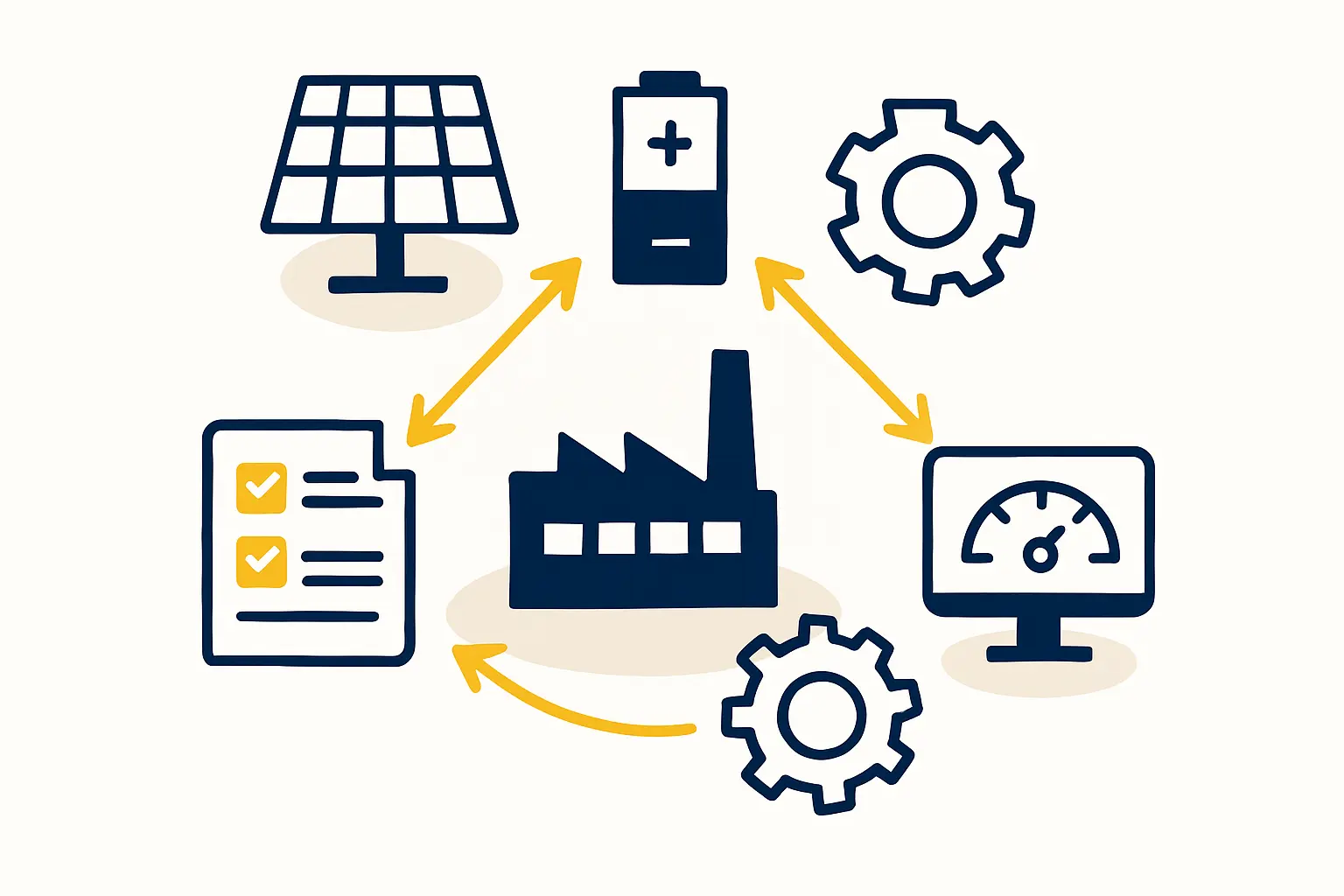

The Strategic Solution: On-site Solar Power and Battery Storage

The most effective way to mitigate the risk of grid instability is to build energy independence directly into the factory’s design. This involves creating a hybrid power system that combines on-site solar generation with a Battery Energy Storage System (BESS).

A typical setup includes:

-

A Rooftop Solar Array: The factory roof provides ample, unused space for a solar installation, turning a passive asset into a productive one. This system generates clean electricity during daylight hours to power operations directly.

-

A Battery Energy Storage System (BESS): Excess solar energy generated during the day is stored in industrial-grade batteries. This stored energy can then power the facility at night, on overcast days, or, most critically, as an uninterruptible power supply (UPS) the instant a grid outage is detected.

-

Grid Connection: The factory remains connected to the national grid. This provides a backup power source and allows the facility to draw power during periods of exceptionally high demand or sell surplus solar energy back to the grid where regulations permit.

This integrated approach transforms the factory from a passive electricity consumer into a resilient, self-sufficient energy hub.

Building the Business Case for Energy Independence

Investing in an on-site power system is not merely an operational safeguard; it is a sound financial and strategic decision. For entrepreneurs planning to start their own solar panel business, this should be a core component of their initial setup.

Operational Continuity and Risk Mitigation

The primary benefit is the near-elimination of production downtime due to grid failures. A BESS can switch over seamlessly, providing uninterrupted power to critical machinery. This protects expensive equipment from damage, prevents material waste, and ensures that production schedules are met.

Cost Management and Predictability

By generating a significant portion of its own electricity, the factory reduces its dependence on grid power. This insulates the business from the fluctuating costs of fossil fuel-based electricity and provides long-term, predictable energy expenses—a crucial advantage when creating a detailed solar panel manufacturing business plan.

Brand Integrity and Market Leadership

A solar factory powered by its own clean energy makes a powerful marketing and branding statement. It demonstrates a genuine commitment to sustainability and technological leadership. This can be a significant differentiator in the marketplace, appealing to environmentally conscious customers and stakeholders both locally and internationally.

Alignment with National Goals

By investing in on-site renewable generation, the business positions itself as a partner in helping Guyana achieve its LCDS 2030 objectives. This alignment can foster positive relationships with governmental bodies and local communities, potentially opening doors for future opportunities.

Frequently Asked Questions (FAQ)

Can a solar factory run entirely off-grid?

While technically possible, maintaining a grid connection is often more practical and cost-effective. A hybrid system provides the best of both worlds: energy independence during outages and the reliability of the grid as a backup. An entirely off-grid system would require oversizing the solar and battery systems to handle all contingencies, increasing the initial investment.

What is the typical payback period for an on-site solar and battery system?

The payback period varies depending on factors like the cost of grid electricity in Guyana, the size of the system, and available government incentives. However, when factoring in the avoided costs of production downtime and wasted materials, the return on investment is often compelling.

Does this add significant complexity to the factory setup?

This solution requires specialized planning and integration during the facility design phase. Working with an experienced partner who understands both the manufacturing process and power system engineering is essential. For investors considering a turnkey solar module manufacturing line, incorporating an on-site power solution should be a key point of discussion with the provider from the outset.

What happens on cloudy days or at night?

That’s precisely what the Battery Energy Storage System (BESS) is for. The batteries store excess energy produced during peak sunlight hours. This stored power is then used when solar generation is low or unavailable, ensuring a consistent 24/7 power supply for critical operations.

A Foundation for Resilient and Profitable Operations

For entrepreneurs entering the solar manufacturing sector in Guyana, planning for energy resilience is not an optional extra—it is fundamental to success. The challenges of an evolving national grid can become a strategic advantage with an on-site solar and battery storage system.

This approach not only secures production continuity and manages operational costs but also builds a powerful brand identity rooted in sustainability and innovation. By tackling the power infrastructure challenge head-on, a new solar factory can build a robust foundation for long-term growth and profitability in this exciting, developing market.