Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For an entrepreneur exploring the energy landscape of Eastern Indonesia, the central challenge is clear. Across more than 17,000 islands, many communities in provinces like Nusa Tenggara and Maluku remain disconnected from a stable power grid. This isn’t just an infrastructure gap; it’s a significant, underserved market. While importing solar modules might seem like a straightforward solution, the logistical complexity and high cost of inter-island transport present substantial barriers.

A more strategic approach is to establish local production tailored to local needs. This business case outlines a lean, semi-automated 25 MW solar module assembly plant—a model designed specifically for the unique economic and geographic conditions of archipelagic regions. It demonstrates how a localized factory can become a profitable venture that also contributes directly to regional energy independence and economic development.

The Strategic Imperative: Local Production for Local Needs

The conventional model of importing finished solar modules from major manufacturing hubs proves inefficient in remote, distributed markets. Standard modules are bulky, fragile, and costly to ship across vast stretches of ocean. Products designed for temperate climates also often lack the long-term durability required in the hot, humid, and saline environments common to coastal Indonesia.

A local, semi-automated assembly plant changes this dynamic. By importing raw materials and assembling modules in-country, a business can significantly reduce shipping costs, minimize transport-related damage, and gain direct control over product quality.

This ‘lean factory’ model isn’t about competing with large-scale international producers; it’s about serving a specific regional market with a superior, purpose-built product. The focus shifts from volume to value, creating modules engineered to perform reliably for decades in the local climate.

Key Parameters of a 25 MW Assembly Plant

A 25 MW annual capacity strikes a good balance for entering the market. It is large enough to achieve economies of scale in material purchasing yet modest enough to align with the investment capacity of many entrepreneurs and the current market demand in emerging regions.

Production Scope and Target Market

The factory’s primary mission would be to supply high-durability modules for off-grid and microgrid applications. These projects power schools, health clinics, small businesses, and households—the backbone of rural electrification.

Production would focus on specialized products like DESERT+ modules, which are engineered for extreme climates. Their construction offers enhanced resistance to heat, humidity, and potential-induced degradation (PID), ensuring a longer operational lifespan and a more reliable return on investment for the end-user. This focus on quality and durability becomes a key competitive advantage over standard imported alternatives.

Investment and Operational Profile

A 25 MW facility represents a manageable investment for a serious business professional. Based on numerous EU PV factory turnkey supplier’s projects, the typical requirements are as follows:

-

Facility Size: The plant requires a dedicated building of 1,500 to 2,000 square meters to house the production line and warehouse raw materials and finished goods.

-

Labor Force: A semi-automated line typically employs between 25 and 35 skilled and semi-skilled workers per shift. This creates valuable local employment and fosters a technical skills base within the community.

-

Automation Level: The semi-automated approach deliberately balances advanced machinery with manual processes. This lowers the initial capital expenditure compared to a fully automated line and provides operational flexibility—a crucial factor in markets where production demands may fluctuate.

The EU-Based Photovoltaic Manufacturing Turnkey Approach

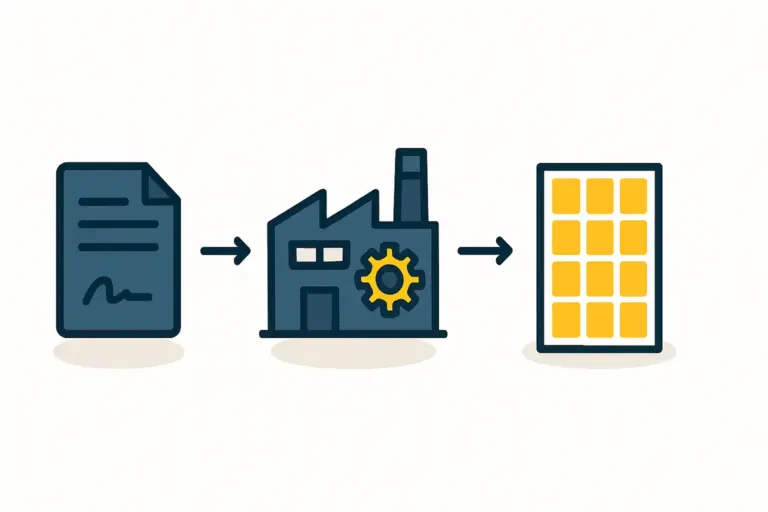

For entrepreneurs without a background in solar engineering, setting up a factory can seem daunting. A turnkey solution from an experienced engineering firm like an established European industrial solutions provider de-risks the entire process. This model encompasses every stage, from initial factory layout and machine selection to installation, staff training, and production ramp-up.

Drawing on decades of experience, this comprehensive support ensures the factory meets international quality standards from day one. It transforms a complex technical challenge into a structured, achievable business project.

Addressing the Unique Challenges of the Indonesian Archipelago

A successful business model must adapt to the realities of its operating environment. In Eastern Indonesia, these are defined by geography, climate, and national policy.

Logistical Hurdles and Supply Chain Resilience

Shipping finished, glass-paned solar modules between hundreds of islands is a logistical nightmare. The risk of breakage is high, and the costs are prohibitive. A local assembly plant circumvents this problem. Raw materials like solar cells, glass, and aluminum frames can be shipped in bulk more efficiently and safely to a central factory. The finished modules are then distributed over shorter, more manageable distances within the target region, building a resilient and cost-effective local supply chain.

Environmental and Climate Considerations

Indonesia’s tropical climate presents a significant technical challenge for photovoltaic technology. High ambient temperatures can reduce energy output, constant humidity can accelerate material degradation, and salt mist in coastal areas can cause corrosion.

A local factory can produce modules engineered to withstand these conditions, ensuring long-term reliability. This may involve using specialized encapsulants, corrosion-resistant framing, and glass-glass construction to protect the solar cells. This commitment to quality ensures that projects powered by these modules are built to last.

Supporting Government Electrification Goals

The Indonesian government has set ambitious targets for increasing the share of renewable energy in its national grid and achieving 100% electrification. Local manufacturing directly supports these national objectives. A factory in an underserved region like Maluku or Nusa Tenggara not only provides the physical tools for electrification but also aligns with policy goals for local content, job creation, and industrial development. This alignment can smooth project approvals and potentially unlock access to government-backed initiatives.

A Model for Sustainable Regional Development

Beyond the immediate business case, a solar module factory can be a catalyst for broader economic growth. The factory serves as an anchor for a new, high-tech industry, creating skilled jobs and reducing the region’s reliance on imported goods.

By providing a reliable source of power, the modules produced enable countless other small businesses to thrive, from refrigerated storage for fishermen to lighting for evening commerce. This model fosters a virtuous cycle: local manufacturing creates local energy security, which in turn powers local economic development.

Frequently Asked Questions (FAQ)

What is the typical timeline for establishing a 25 MW factory?

With a structured turnkey partner approach, the project timeline from contract signing to the start of production is typically 9 to 12 months. This includes machine manufacturing, shipping, installation, and staff training.

Do I need a technical or engineering background to start this business?

No. The turnkey model is designed for business professionals and entrepreneurs from diverse backgrounds. The engineering partner provides all the necessary technical expertise, process knowledge, and training to ensure the local team can operate the factory successfully.

What are the primary raw materials required for production?

The key components include solar cells, tempered front glass, backsheets or rear glass, EVA or POE encapsulant films, aluminum frames, and junction boxes with cables. A turnkey provider can help establish reliable supply chains for these materials.

How does a semi-automated line compare to a fully automated one?

A semi-automated line requires a lower initial capital investment, offers greater production flexibility, and creates more local jobs. For a 25 MW capacity in an emerging market, it often presents a more balanced and financially sound business model than a fully automated setup, which is better suited for gigawatt-scale factories in established industrial hubs.

Conclusion and Path Forward

Establishing a 25 MW semi-automated solar module factory in Eastern Indonesia is more than a viable business proposal—it is a strategic response to the region’s pressing need for distributed, resilient energy. It offers a clear path to profitability by addressing a well-defined market with a purpose-built, high-quality product.

This model transforms logistical challenges into competitive advantages and aligns commercial goals with national development priorities. For entrepreneurs ready to build a lasting enterprise, it represents an opportunity to power a region’s future.

For those considering this path, the next step involves detailed financial modeling and technical planning. The pvknowhow.com e-course provides a structured framework to help you develop a comprehensive business plan and take the next step on this journey.

Download the 25 MW Indonesia Solar Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.