An entrepreneur invests millions in state-of-the-art solar manufacturing machinery from Europe. The equipment arrives on schedule at the Port of Yokohama—a significant milestone. The entire process, however, grinds to a halt over a small discrepancy in the Harmonized System (HS) code on the import declaration.

As the containers sit at the port, demurrage fees accumulate daily, turning a minor logistical detail into a costly operational crisis. This scenario is more common than many new entrants to the solar industry anticipate, especially in a market as precise and regulated as Japan.

Understanding the logistical landscape isn’t just an administrative task; it is a critical component of a project’s financial planning and timeline. Here, we break down the logistical challenges and associated costs of shipping solar production machinery and raw materials to major Japanese ports such as Yokohama, Kobe, or Tokyo. This guide is designed to equip entrepreneurs with the practical knowledge needed to navigate this complex process successfully.

Navigating Japan’s Major Ports: Efficiency Meets Congestion

Japan’s port infrastructure is among the most advanced in the world. While facilities in Yokohama, Kobe, and Tokyo are known for their efficiency and technological integration, this high level of activity also creates significant challenges that must be factored into any project plan.

Port congestion is a persistent issue. Heavy vessel traffic can lead to waiting times for berthing, while crowded container yards can slow the process of locating and moving specific shipments. For an entrepreneur setting up a new production facility, these delays are not merely inconvenient—they directly impact project timelines and budgets.

Key challenges at major Japanese ports include:

- Vessel Queues: During peak seasons, ships may have to wait for days before they can dock and unload.

- Terminal Congestion: Once unloaded, containers must be moved from the terminal. Limited space can cause bottlenecks that delay the release of cargo.

- Demurrage and Detention Fees: These charges are levied by shipping lines when containers are not moved out of the port within a specified free period. Customs delays can cause these fees to escalate quickly, from hundreds to thousands of dollars per day.

Minimizing time spent at the port and avoiding these punitive charges requires effective planning alongside an experienced local logistics partner.

The Critical Role of Customs and Documentation

The Japanese customs authority is renowned for its meticulousness and strict adherence to regulations, leaving no room for error in documentation. For an investor importing high-value solar module manufacturing equipment, even a minor mistake on a commercial invoice or packing list can lead to inspections, re-valuations, and costly delays.

The single most critical element is the correct classification of goods using the Harmonized System (HS) code, which determines the import duties and taxes for the shipment.

- HS Code Precision: While much industrial machinery may qualify for duty-free entry, an incorrect code can trigger duties and, more importantly, a full customs review. A multifunction laminator, for example, might have a different classification than a standalone stringer machine.

- Documentation Accuracy: All documents—the Bill of Lading, Commercial Invoice, Packing List, and Certificate of Origin—must be perfectly consistent. The description of goods, their value, weight, and quantity must match across all paperwork, as any discrepancy is a red flag for customs officials.

- Consumption Tax: All imports into Japan are subject to a 10% consumption tax, calculated on the CIF (Cost, Insurance, and Freight) value of the goods plus any applicable customs duties. This cost must be accurately budgeted.

Experience from J.v.G. turnkey projects shows that engaging a professional customs broker with specific experience in industrial machinery is not an optional expense but a necessary investment in a smooth clearance process.

A Breakdown of Key Import Costs

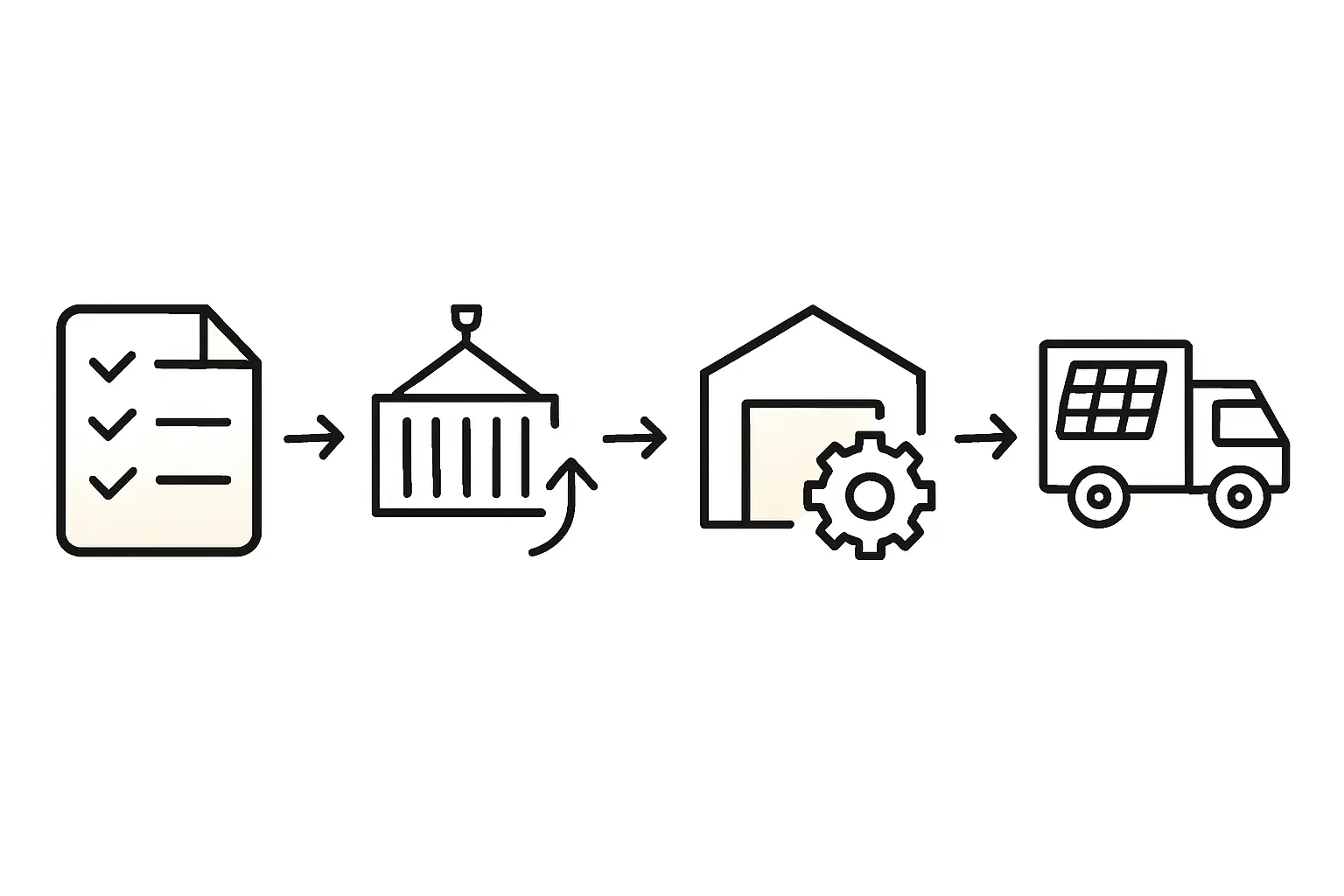

Budgeting for shipping involves more than just the freight rate. A comprehensive financial plan needs to account for a range of costs, from the factory of origin to the final installation site. Below is a breakdown of typical cost components for shipping to Japan.

Ocean Freight

This is the cost to transport a container from the port of origin to the port of destination. Rates are volatile and depend on the route, carrier, and time of year.

- 40-foot container (Machinery) from China to Yokohama: Approximately $2,500 – $4,500

- 40-foot container (Raw Materials) from Europe to Kobe: Approximately $3,500 – $6,000

Insurance

Protecting high-value equipment is non-negotiable. Marine cargo insurance typically covers loss or damage during transit.

- Typical Cost: 0.5% to 1.0% of the total cargo value (CIF value). For a $1 million shipment of machinery, this would be $5,000 to $10,000.

Port and Handling Fees

These local charges at both the port of origin and destination cover services like loading and unloading the container from the vessel and moving it within the terminal.

- Terminal Handling Charges (THC): Approximately $500 – $1,200 per container in Japan.

Customs Clearance and Brokerage

This fee covers the services of a licensed customs broker who prepares and submits the necessary documentation.

- Brokerage Fees: Approximately $200 – $500 per shipment.

Inland Transportation

Moving equipment from the port to the factory site is often an underestimated cost, particularly for oversized cargo.

- Standard Container (100 km): Approximately $800 – $2,000.

- Oversized Machinery: Costs can be significantly higher, requiring special permits, escort vehicles, and route planning that could exceed $10,000 depending on the distance and complexity.

Contingency Planning

Given the potential for unforeseen delays, allocating a contingency fund is simply good business practice.

- Recommended Buffer: A 15-20% contingency on the total logistics budget is advisable to cover potential demurrage, customs inspections, or unexpected transport challenges.

Special Considerations for Solar Materials and Machinery

Different types of cargo present unique challenges. The machinery and raw materials required for solar panel production have distinct logistical needs.

- Oversized Machinery: Equipment like laminators or large glass washers often exceeds the dimensions of a standard container. Such cargo must be shipped as break-bulk or on flat-rack containers, which involves more complex handling and higher costs.

- Sensitive Materials: Ethylene Vinyl Acetate (EVA) and backsheets are sensitive to humidity and temperature fluctuations. They may require climate-controlled containers (“reefers”) and specialized warehousing, adding to the overall cost.

- Fragile Components: Solar glass is inherently fragile and requires robust, professional crating to prevent breakage during transit. Insurance premiums for such items are often higher.

- High-Purity Materials: Polysilicon must be handled carefully to avoid contamination, a process that requires specialized packaging and handling protocols.

Failing to account for these specific requirements can result in damaged goods, rendering them useless for production and causing severe project setbacks.

Frequently Asked Questions (FAQ)

Why are Japanese customs so strict?

Japanese customs procedures are built on a culture of precision and regulatory compliance to ensure safety, security, and the correct collection of revenue. This meticulous approach means there is very little tolerance for ambiguity or errors in paperwork, which are seen as a reflection of the importer’s professionalism.

What is the most common mistake for a first-time importer to Japan?

The most frequent and costly error is incomplete or inconsistent documentation. This includes mismatches between the commercial invoice and packing list, vague descriptions of goods, or incorrect valuation. Such mistakes immediately raise red flags and often lead to lengthy, expensive customs inspections.

Is it possible to manage the logistics process independently to reduce costs?

While technically possible, it is highly inadvisable for anyone without deep expertise in Japanese import regulations and logistics. The potential costs from errors—such as demurrage fees, customs penalties, and production delays—far outweigh any savings from forgoing a professional freight forwarder and customs broker. This is a critical step in setting up your solar production line successfully.

How far in advance should shipment planning begin?

For complex industrial machinery, planning should begin at least three to six months before the expected shipping date. This window allows sufficient time to coordinate with the manufacturer, book vessel space, prepare all necessary documentation meticulously, and arrange for specialized inland transport in Japan.

Summary and Next Steps

Importing solar manufacturing equipment and materials into Japan is a complex undertaking where precision and planning are paramount. The costs extend far beyond the initial freight quote, encompassing customs duties, port fees, specialized handling, and inland transport. More importantly, procedural errors can lead to delays that jeopardize the entire project timeline.

By understanding these challenges and budgeting for a comprehensive logistics strategy—one that includes a contingency fund and experienced local partners—an entrepreneur can navigate the process successfully. This foundational work is essential for anyone serious about building a viable solar manufacturing operation.

For those ready to plan their project, our comprehensive guide on how to start a solar factory provides the structured framework needed to turn an ambitious idea into a successful enterprise.