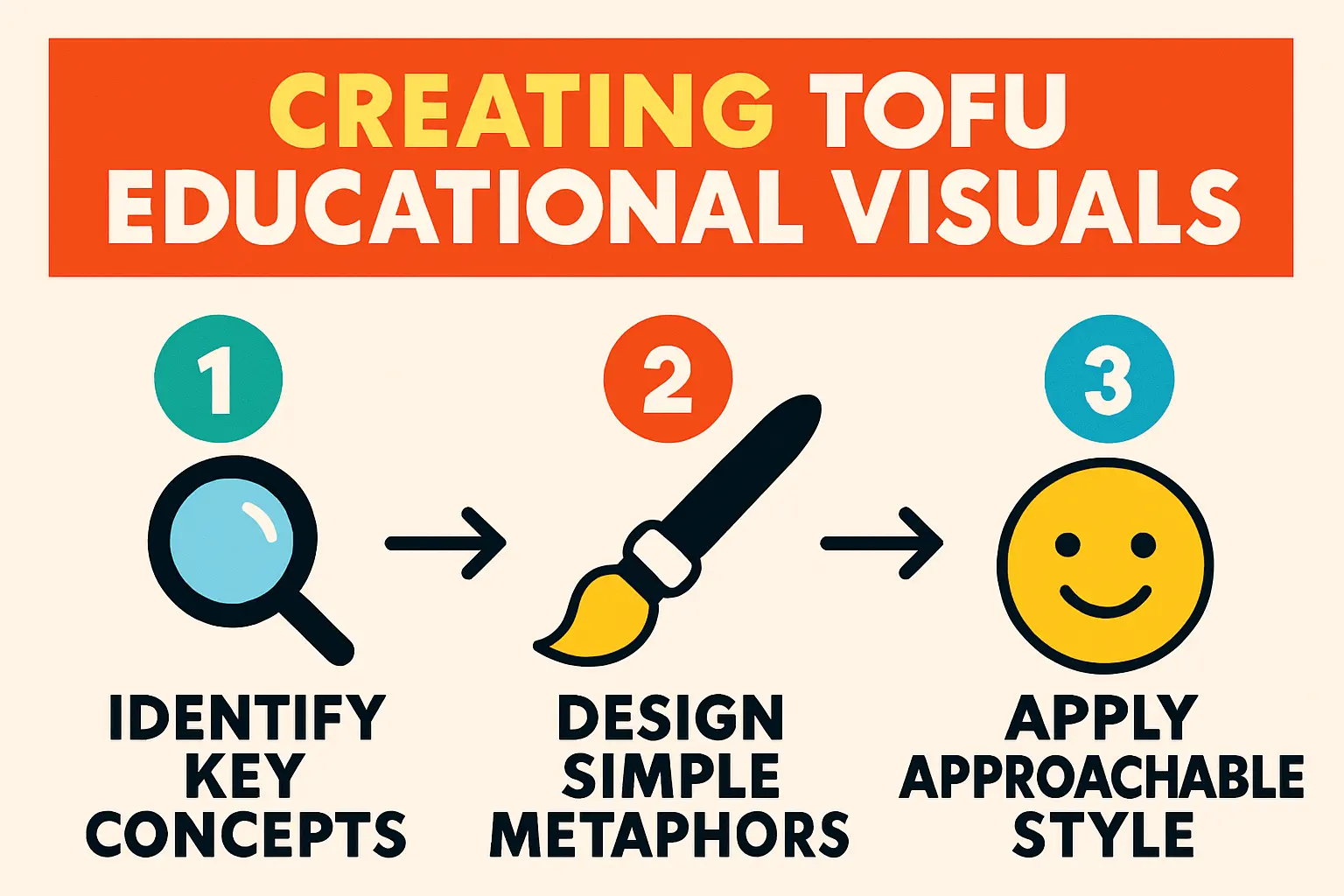

When planning a new solar module manufacturing plant, entrepreneurs often focus on capital expenditures like machinery and building costs. However, the cost and reliability of the electricity supply are significant recurring operational expenditures (OpEx) that can heavily influence profitability.

For an energy-intensive facility like a solar factory, understanding the nuances of grid connectivity and industrial power tariffs in a market like Kazakhstan is not just an operational detail—it is a strategic necessity.

This article breaks down the electrical infrastructure landscape in Kazakhstan, offering guidance for business professionals evaluating a move into solar module production.

Understanding Kazakhstan’s Industrial Power Landscape

Kazakhstan’s energy sector presents a unique mix of opportunities and challenges for industrial consumers. The country’s electricity generation is predominantly powered by coal, accounting for approximately 70% of the total supply. This reliance on fossil fuels results in relatively low electricity prices but also has implications for grid infrastructure and future environmental policies.

A critical factor for any new industrial project is the regional division of the country’s power grid into three distinct zones:

-

Northern Zone: Historically an energy-surplus region, it benefits from close proximity to major coal-fired power plants. This area generally offers more reliable power and competitive tariffs.

-

Southern Zone: An energy-deficit region that often relies on electricity imports from the North or neighboring countries. This can lead to higher transmission costs, potential grid instability, and less predictable supply.

-

Western Zone: Largely self-sufficient due to its significant oil and gas resources, this zone has its own distinct grid characteristics and tariff structures.

For a prospective solar module manufacturer, the choice of location within Kazakhstan is directly linked to the cost and stability of the factory’s power supply.

Decoding Industrial Electricity Tariffs

The cost of electricity for industrial users in Kazakhstan is a primary driver of a factory’s operating costs. While tariffs are government-regulated, they are not uniform across the country. Several factors influence the final price per kilowatt-hour (kWh):

-

Regional Variation: Tariffs differ significantly between the energy zones, with the Southern deficit zone often having higher prices than the Northern surplus zone.

-

Transmission and Distribution Costs: The final tariff includes charges for transporting electricity from the power plant to the factory.

-

Time-of-Use Tariffs: Some regional electricity companies may offer differentiated tariffs for peak and off-peak consumption, which can be leveraged to optimize production schedules.

As of recent analyses, average industrial electricity tariffs in Kazakhstan typically range from 24 to 30 KZT per kWh (approximately $0.05 to $0.07 USD). While this is globally competitive, obtaining precise, current quotes from the regional electric grid company (REK) for a specific project location is crucial. A seemingly small difference in tariffs can amount to a substantial sum over a year of continuous factory operation.

A detailed analysis of these costs should be a core part of any business plan. The initial investment for a solar factory is only one part of the financial equation; ongoing operational expenditures will determine long-term viability.

The Grid Connection Process: A Practical Overview

Securing a reliable high-voltage connection to the national grid is a critical milestone for any new manufacturing plant. In Kazakhstan, this process is manageable but requires careful planning and navigation of administrative procedures.

The typical steps involved include:

-

Initial Application: Submitting a formal request to the local REK with details of the required power capacity (load), facility location, and planned operational schedule.

-

Technical Specification (Tekhnicheskiye Usloviya): The REK provides a technical specification document outlining the requirements for the connection, including substation standards, cable types, and safety protocols.

-

Project Design and Approval: A licensed engineering firm must design the connection infrastructure based on the technical specifications. This design then requires approval from the REK and other state authorities.

-

Construction and Installation: The physical construction of the substation and connection lines is undertaken.

-

Inspection and Commissioning: The REK inspects the completed installation to ensure it complies with all technical and safety standards before energizing the connection.

Based on experience from J.v.G. turnkey projects, underestimating the timeline for this process is a common oversight. It can take anywhere from 6 to 18 months to complete all steps. Initiating discussions with the local grid operator should be one of the first priorities after site selection.

Grid Stability: A Critical Operational Risk

Beyond cost, grid stability is a paramount concern for a solar module factory. Modern manufacturing equipment—such as laminators, cell stringers, and testers—contains sensitive electronics vulnerable to voltage fluctuations, frequency deviations, or sudden power outages.

An unexpected power interruption can lead to:

-

Production Loss: An entire batch of modules inside a laminator can be ruined if the heating and pressure cycle is interrupted, leading to material waste and lost revenue.

-

Equipment Damage: Sudden power surges or drops can damage sensitive electronic components, resulting in costly repairs and extended downtime.

-

Quality Control Issues: Inconsistent power can affect the precision of automated processes, potentially leading to defects that compromise the final product’s quality and certification.

These risks are particularly pronounced in regions with aging infrastructure or in energy-deficit zones. This makes a thorough assessment of the local grid’s historical performance a crucial part of due diligence.

Mitigation Strategies for Power-Related Risks

To safeguard operations, manufacturers can implement several mitigation strategies. The choice depends on the local grid’s reliability and a cost-benefit analysis.

-

Uninterruptible Power Supply (UPS): For critical control systems and servers, a UPS can provide instantaneous battery backup during short outages.

-

Backup Diesel Generators: For longer disruptions, diesel generators can power essential machinery to complete production cycles or allow for a safe shutdown.

-

Voltage Stabilizers: Installing power conditioning equipment can protect sensitive electronics from harmful voltage fluctuations.

Carefully selecting the right manufacturing equipment with built-in power tolerance features can also reduce operational risks.

Frequently Asked Questions (FAQ)

What is a typical electricity cost per solar module produced in Kazakhstan?

This depends on the factory’s efficiency and local tariffs. As a rough estimate, a modern 550W module requires approximately 10-12 kWh of electricity to produce. At an average tariff of 27 KZT/kWh, the electricity cost would be around 270-324 KZT per module.

How long does it typically take to get a new industrial grid connection in Kazakhstan?

The process, from initial application to final commissioning, can range from 6 to 18 months. Early engagement with the regional electric grid company is essential to avoid delays.

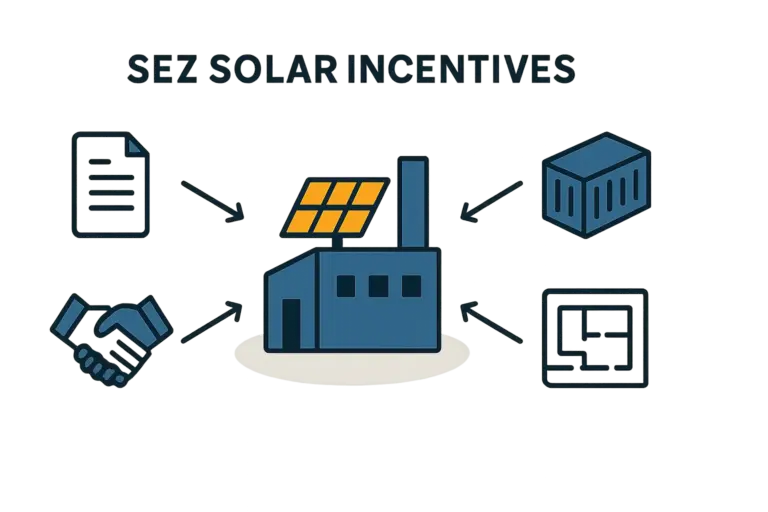

Are there any government subsidies on electricity for new manufacturing ventures?

Kazakhstan offers various investment incentives through special economic zones (SEZs) or specific government programs. These may include reduced tariffs or other benefits. It is advisable to consult with government investment agencies like Kazakh Invest to explore available support.

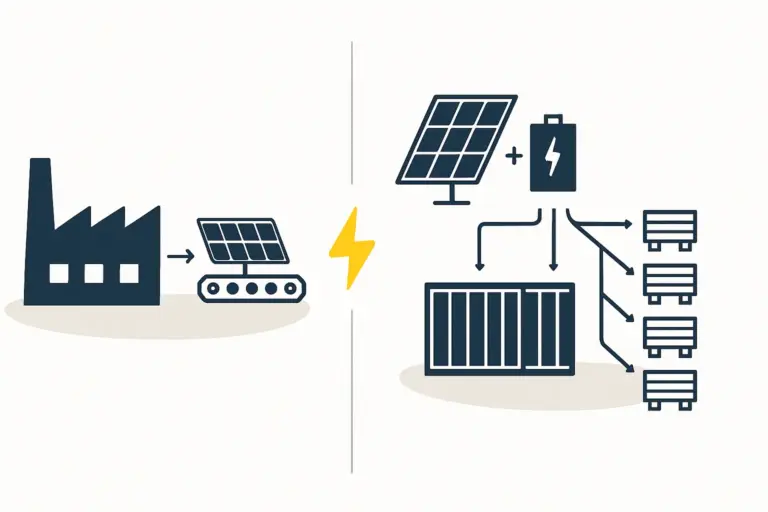

Can a solar module factory run completely ‘off-grid’?

While technically possible with a massive investment in captive power generation (e.g., a large solar farm with battery storage), it is not economically viable for most ventures. A factory’s power demand is substantial and requires a stable, high-capacity source that the national grid provides most cost-effectively.

Conclusion: Integrating Power Strategy into Your Business Plan

The cost and reliability of electricity are fundamental to the success of a solar module factory in Kazakhstan. A proactive approach is essential—one that involves careful site selection based on regional energy infrastructure, early engagement with grid operators, and a clear understanding of tariff structures.

By treating grid connectivity not as a simple utility but as a strategic asset, investors can mitigate significant operational risks and build a more resilient and profitable manufacturing business. This due diligence is a non-negotiable step before securing the necessary building permits and committing to capital investments.