An entrepreneur looking to enter the Kazakh solar market might assume that success hinges on competitive pricing and product quality alone. But a crucial third element often determines access to the nation’s most significant opportunities: government-backed projects. For these tenders, the deciding factor is not just where a solar module is assembled, but how it is made.

Understanding and meeting the ‘Made in Kazakhstan’ criteria is the gateway to the country’s ambitious renewable energy auctions. This article outlines the manufacturing operations required to achieve this status and explains why it is a fundamental strategic consideration for any serious investor in the region.

The Strategic Importance of ‘Made in Kazakhstan’ Status

The government of Kazakhstan has set a clear objective to generate 50% of its energy from renewable sources by 2050. To stimulate investment and achieve this goal, it has implemented supportive policies, most notably offering 20-year fixed tariffs through competitive auctions.

These government-backed projects provide a stable, long-term revenue stream that is highly attractive to new manufacturers. Participation in these auctions, however, is contingent upon meeting Local Content Requirements (LCR). The ‘Made in Kazakhstan’ certification is not a mere formality; it is a prerequisite for supplying state-sponsored initiatives.

Achieving this status gives a manufacturer a decisive competitive advantage, unlocking access to the largest and most secure segment of the market. Failing to meet these criteria effectively excludes a producer from these key opportunities, regardless of the product’s price or efficiency.

Defining ‘Made in Kazakhstan’: The Six Essential Manufacturing Operations

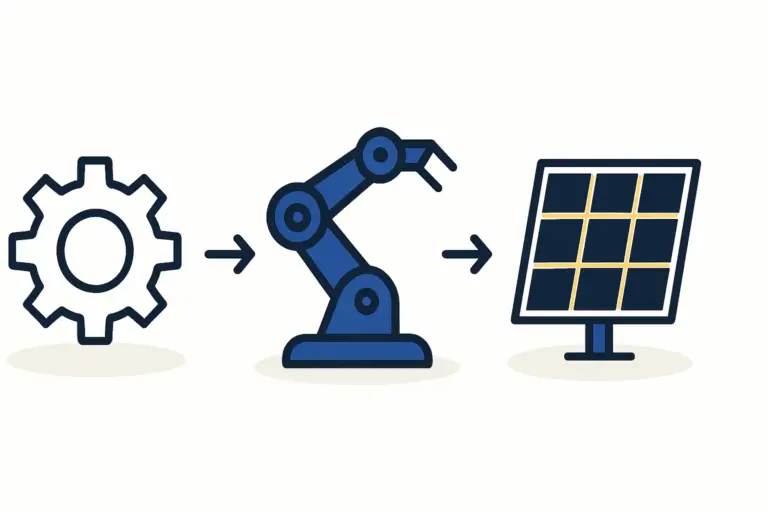

Achieving ‘Made in Kazakhstan’ status requires more than final assembly. Regulations mandate that specific, value-adding manufacturing processes must be performed locally. A solar module is considered locally produced only if the manufacturer can document the performance of six key operations within its Kazakh facility.

The required steps are as follows:

-

Cell Stringing and Interconnection: This initial stage involves soldering metallic ribbons (interconnectors) to individual solar cells to connect them electrically into a series, forming a ‘string’.

-

Laying of Interconnected Cell Strings: The completed cell strings are precisely positioned and arranged on the module’s glass and encapsulant layers, forming the matrix that will become the core of the solar panel.

-

Lamination of the Module: The assembled layers—glass, encapsulant, cell matrix, and backsheet—are placed into a laminator. Here, heat and vacuum bond the layers into a single, durable, and weatherproof unit known as the laminate.

-

Framing of the Laminate: An aluminum frame is fitted and secured around the edges of the laminate. This frame provides structural rigidity, protects the edges from damage, and offers a means for mounting the module.

-

Installation of the Junction Box: The junction box, which houses the bypass diodes and output cables, is affixed to the rear of the module. This component serves as the electrical interface for connecting the module to other panels in a solar array.

-

Testing of Electrical Parameters: Each finished module undergoes a final quality control test in a sun simulator. This test measures its actual electrical output (e.g., power, voltage, current) to ensure it meets specified performance ratings and quality standards.

Performing only a subset of these tasks, such as framing an imported laminate, is insufficient. A compliant facility must be equipped and staffed to execute all six operations.

From Requirements to Reality: Setting Up a Compliant Factory

Translating these six requirements into a functioning factory demands careful planning and investment in the right equipment. Each operation corresponds to a specific station or machine group within the production process. A facility designed for compliance must integrate these capabilities from the outset.

Based on experience from J.v.G. turnkey projects, incorporating these requirements from the beginning is far more efficient than attempting to retrofit a simple assembly workshop later. The entire factory layout, workflow, and equipment selection must be oriented around fulfilling these manufacturing stages. This approach ensures not only regulatory compliance but also operational efficiency and product quality.

The foundation for this process is a detailed solar module manufacturing business plan that accounts for these local content rules. Such a plan would outline the necessary machinery, facility specifications, and required operational workflows. The equipment needed to perform these six operations—including stringer machines, layup stations, laminators, framing tables, and testing simulators—constitutes the core of a modern solar panel production line. For a typical 20–50 MW setup, planning for these integrated capabilities is essential for a successful market entry.

Frequently Asked Questions (FAQ)

Do these requirements apply to all solar projects in Kazakhstan?

These local content requirements are primarily a prerequisite for participating in government-sponsored tenders and auctions with fixed tariffs. While not strictly mandatory for private or commercial sales, holding the ‘Made in Kazakhstan’ certificate provides a significant competitive and marketing advantage across the entire domestic market.

Can a manufacturer start with a smaller operation and expand later?

Yes, a modular or phased approach is possible. However, to achieve certification, the initial production line must be capable of performing all six mandated operations from day one. While an entrepreneur can begin with a lower capacity (e.g., 20 MW) and later add a second line to increase output, this foundational capability must be present from the start.

What is the typical investment for a compliant production line?

Investment levels vary based on capacity, automation level, and choice of equipment suppliers. However, an entrepreneur planning a 20–50 MW facility capable of meeting these local content rules should anticipate a multi-million dollar investment for production machinery, facility setup, and initial working capital.

How long does it take to establish a factory that meets these standards?

With a clear plan, qualified partners, and efficient project management, a turnkey solar module production line can be operational in under 12 months, from initial planning to the production of the first certified module.

Your Path Forward in the Kazakh Solar Market

For any professional looking to enter Kazakhstan’s solar manufacturing sector, understanding local content requirements is not an administrative detail—it is the cornerstone of a viable business strategy. The ‘Made in Kazakhstan’ status is the key that unlocks the most stable and scalable opportunities within the market.

While the technical requirements may seem detailed, they follow a logical production sequence that is standard in modern module manufacturing. The journey from initial concept to a fully compliant, operational factory is a structured one. Educational resources, such as the structured e-course provided by pvknowhow.com, can help business leaders navigate each stage of planning, from factory design to equipment selection and final certification.