For international investors exploring Africa, Kenya offers a compelling opportunity for solar panel manufacturing, driven by abundant sunshine and growing energy demand.

A venture’s success, however, isn’t determined by market potential alone. It relies fundamentally on the bedrock of national infrastructure: a reliable power grid, efficient transport networks, and strategic industrial zones.

While an entrepreneur’s focus is often on the factory itself—the machinery, the production line, the workforce—the most critical factors for profitability and operational stability lie outside its walls. This article provides a realistic assessment of Kenya’s essential infrastructure, offering a clear-eyed view for professionals planning to enter the photovoltaic manufacturing sector.

The Power Paradox: High Renewables, Unstable Grid

The stability of the electrical supply is a primary concern for any energy-intensive manufacturing process, and in Kenya, this presents a unique paradox.

On one hand, the country is a leader in renewable energy generation. According to the Energy and Petroleum Regulatory Authority (EPRA), Kenya derives approximately 90% of its electricity from renewable sources, primarily geothermal, hydro, and wind power. This commitment to green energy resonates with the ethos of the solar industry.

The reality on the ground for industrial users, however, presents significant challenges. Data from the World Bank and local business surveys reveal that many firms in Kenya experience an average of 5 to 10 significant power outages per month. These interruptions, along with accompanying voltage fluctuations, pose a direct threat to the sensitive, expensive equipment used in solar module production.

Why Grid Stability is Non-Negotiable

In a solar panel factory, an unexpected power loss can have cascading consequences:

- Equipment Damage: Automated machinery like cell stringers and laminators can be damaged by sudden shutdowns or power surges upon restoration.

- Production Waste: A power cut during a lamination cycle, for example, can render an entire batch of modules unusable, leading to significant material losses.

- Operational Downtime: Each hour of downtime is an hour of lost production, directly impacting output targets and revenue.

Investors must treat backup power not as an optional extra but as a core component of their operational strategy. This means planning for a robust system of diesel generators and, increasingly, Battery Energy Storage Systems (BESS). The cost of this redundant power infrastructure must be factored into the initial investment. Experience from J.v.G. turnkey projects shows that underestimating backup power needs is one of the most common and costly oversights for new entrants in emerging markets.

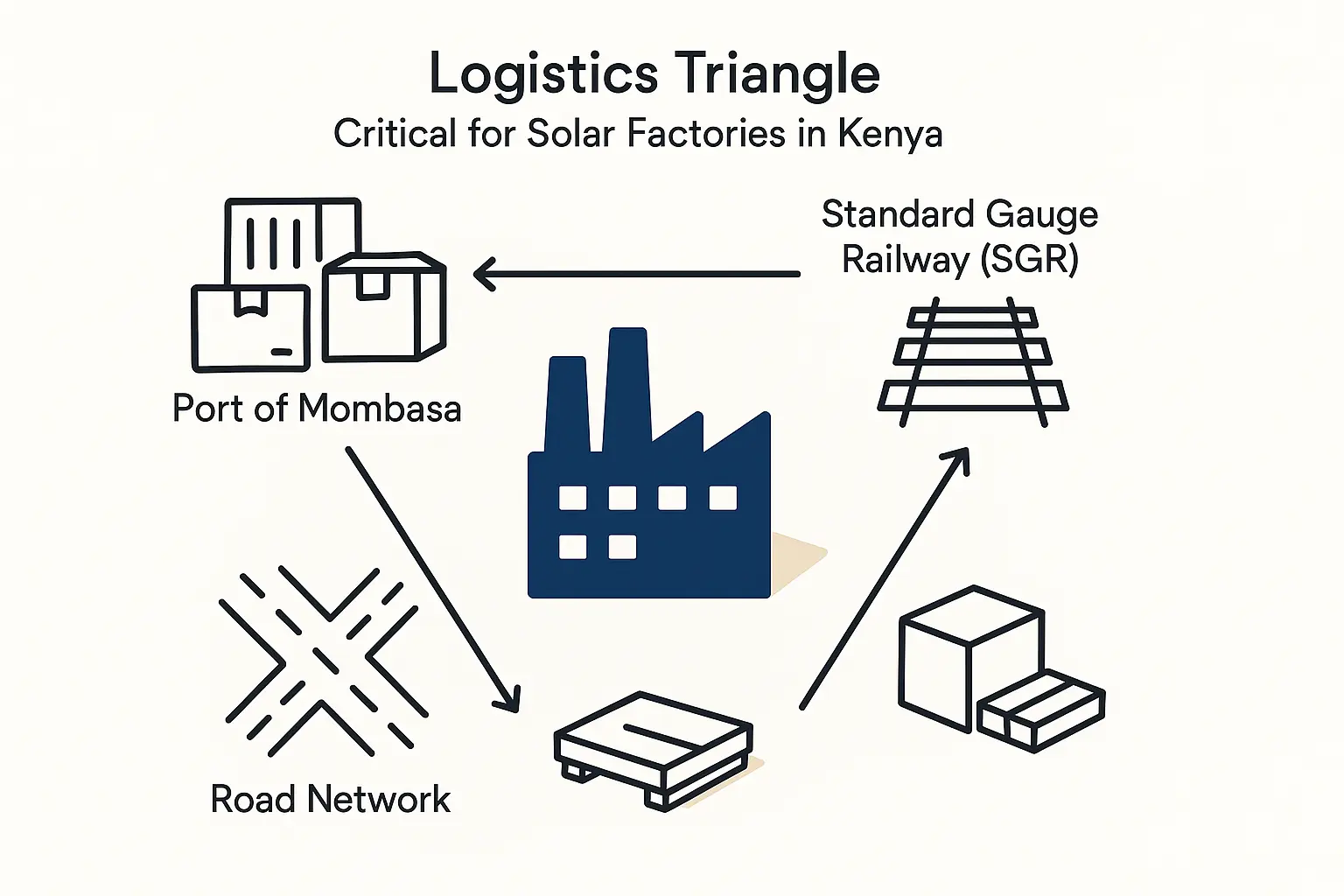

From Port to Plant: Navigating Kenya’s Logistics Network

A solar factory’s operation depends on a constant flow of inbound raw materials and outbound finished goods, making efficient transportation its lifeblood. Since key materials like solar glass, EVA foil, and photovoltaic cells are typically imported, port access becomes a critical starting point.

The Port of Mombasa: Gateway to East Africa

The Port of Mombasa is the primary maritime gateway for Kenya and much of East Africa. It is one of the most active ports on the continent, handling over 1.4 million TEUs (twenty-foot equivalent units) annually. Recent infrastructure upgrades have improved vessel turnaround times and container handling efficiency.

However, a successful logistics chain doesn’t end at the port. The journey from Mombasa to an inland factory requires a careful evaluation of road and rail infrastructure.

Inland Transportation: Road and Rail

- Standard Gauge Railway (SGR): The SGR provides an efficient freight link between Mombasa and the capital, Nairobi, with extensions planned towards western Kenya. For factories located near its main hubs, the SGR can significantly reduce transit time and cost for bulk materials.

- Road Network: While major arteries are in good condition, Kenya’s overall road network has limitations, with only about 20% of it being paved. Consequently, “last-mile” transport from a rail depot or main highway to the factory site can become a bottleneck. The condition of these access roads can delay delivery schedules and increase the risk of damage to sensitive goods.

A thorough logistics analysis—accounting for shipping costs, customs clearance times, inland freight options, and potential delays—is an essential part of any solar panel manufacturing business plan.

Strategic Site Selection: Leveraging Special Economic Zones (SEZs)

Choosing the right factory location is a strategic decision that must balance both power and transport challenges. To attract foreign investment, the Kenyan government has actively promoted Special Economic Zones (SEZs) and Export Processing Zones (EPZs)—designated areas that offer a compelling package of benefits to overcome these infrastructural hurdles.

Advantages of Locating in a Kenyan SEZ

For a new solar manufacturing enterprise, establishing a facility within an SEZ offers distinct advantages:

- Enhanced Infrastructure: SEZs typically provide more reliable power and water supplies, high-quality road access, and pre-installed utility connections, reducing setup time and costs.

- Fiscal Incentives: These zones often come with significant tax benefits, including corporate tax holidays, exemptions from VAT, and reduced import/export duties on raw materials and equipment.

- Streamlined Bureaucracy: SEZs usually operate under a simplified regulatory framework with dedicated administrative bodies (“one-stop shops”) to assist with permits, licenses, and customs clearance. This can be invaluable for navigating an unfamiliar business environment.

Notable zones include the Naivasha Special Economic Zone, with its access to abundant geothermal power, and Konza Technopolis, positioned as a hub for technology and light manufacturing. Leveraging the structured environment of an SEZ can significantly de-risk and simplify the process of establishing a solar factory.

Frequently Asked Questions (FAQ)

-

Why is stable power from the grid not sufficient for a solar factory in Kenya?

While the grid’s high share of renewables is a plus, its lack of reliability is the primary concern. The frequency of outages and voltage fluctuations, even brief ones, can halt production, spoil materials during sensitive processes like lamination, and potentially damage multi-million dollar machinery. A dedicated backup power system is essential to ensure continuous production and protect the investment. -

Can all raw materials for solar panels be sourced within Kenya?

Currently, most of the core, high-technology components—such as photovoltaic cells, specialized solar glass, and encapsulant foils (EVA/POE)—must be imported, primarily from Asia. This makes efficient port and customs operations, as well as reliable inland transport, critical for maintaining the supply chain. -

Are SEZs significantly more expensive to operate in?

While land lease or purchase costs within an SEZ might be higher than in a rural location, this is often offset by substantial savings. The financial benefits from tax incentives, coupled with the operational savings from reliable infrastructure and reduced bureaucratic delays, typically result in a lower total cost of ownership and a faster path to profitability. -

What is the most important first step when evaluating a potential site in Kenya?

The first step is a thorough due diligence process that goes beyond a desktop study. It should involve a site visit to assess the actual condition of access roads, confirm the proximity and capacity of electrical substations, and engage with the administrators of any potential SEZs. This groundwork is crucial for validating the assumptions made in the initial business plan.

Conclusion: Building on a Solid Foundation

Kenya offers fertile ground for solar panel manufacturing, driven by strong market fundamentals and a supportive government. However, success ultimately depends on a clear-eyed understanding of the country’s infrastructural landscape.

By proactively planning for grid instability, carefully mapping a resilient logistics chain, and strategically leveraging Special Economic Zones, investors can mitigate risks and build a robust, competitive operation. Understanding these foundational elements is the first critical step toward turning Kenya’s solar potential into a tangible business success.

For investors seeking a broader perspective on the country’s business climate and market dynamics, our complete guide on Kenya as a location for solar manufacturing offers deeper context.