Demand Dynamics: Market Size & Export Potential for Kenyan Solar Modules

For any entrepreneur exploring a new industrial sector, a deep understanding of the market is fundamental. When it comes to solar manufacturing in Kenya, the central question is: Is there enough demand to justify building a local production facility? While the country enjoys abundant sunshine, the business case ultimately rests on real-world market forces, both within Kenya’s borders and beyond.

This analysis offers a high-level overview of the demand drivers and export opportunities for locally made solar modules. It explores current market size, growth projections, and the strategic advantages of producing in Kenya for the wider East African region—all crucial factors in the overall investment case.

The Untapped Domestic Demand in Kenya

The demand for reliable energy in Kenya is strong and varied. The national grid, while expanding, faces challenges with reliability and reach, creating distinct opportunities for solar power solutions.

Key drivers of domestic demand include:

-

Rural Electrification: A significant portion of the population, particularly in rural areas, still lacks access to consistent electricity. Off-grid and mini-grid solar systems represent the most viable and cost-effective solution for electrifying these communities.

-

Commercial & Industrial (C&I) Sector: For businesses, grid instability leads to operational disruptions and financial losses, while high electricity tariffs eat into profits. As a result, many enterprises are turning to solar power to ensure a stable energy supply and reduce long-term operational costs.

-

Government Support: The Kenyan government actively promotes solar energy through its Vision 2030 and National Electrification Strategy. Favorable policies, including exemptions from Value Added Tax (VAT) and import duties on renewable energy equipment, create a supportive environment for market growth.

Together, these factors fuel a significant and growing market. According to industry analysis, the Kenyan solar energy market was valued at approximately USD 65.2 million in 2022 and is projected to reach USD 171.6 million by 2030, growing at a compound annual growth rate (CAGR) of 13.5%.

This steady growth trajectory signals a sustainable domestic market for any investor looking to establish a local manufacturing presence.

Kenya’s Geographic Advantage: A Foundation for Manufacturing

Kenya benefits from high levels of solar irradiation, receiving 4–6 kilowatt-hours per square meter (kWh/m²) per day. This natural resource is the primary fuel for any solar panel, making the country an inherently suitable location for solar energy generation and, by extension, module manufacturing.

This abundance of sunshine is not merely an environmental benefit; it is a core economic asset. It ensures that panels installed in the region will perform optimally, delivering strong returns for end-users and reinforcing the value of solar technology in the local market. For a manufacturer, this geographic advantage forms the very foundation of the business model.

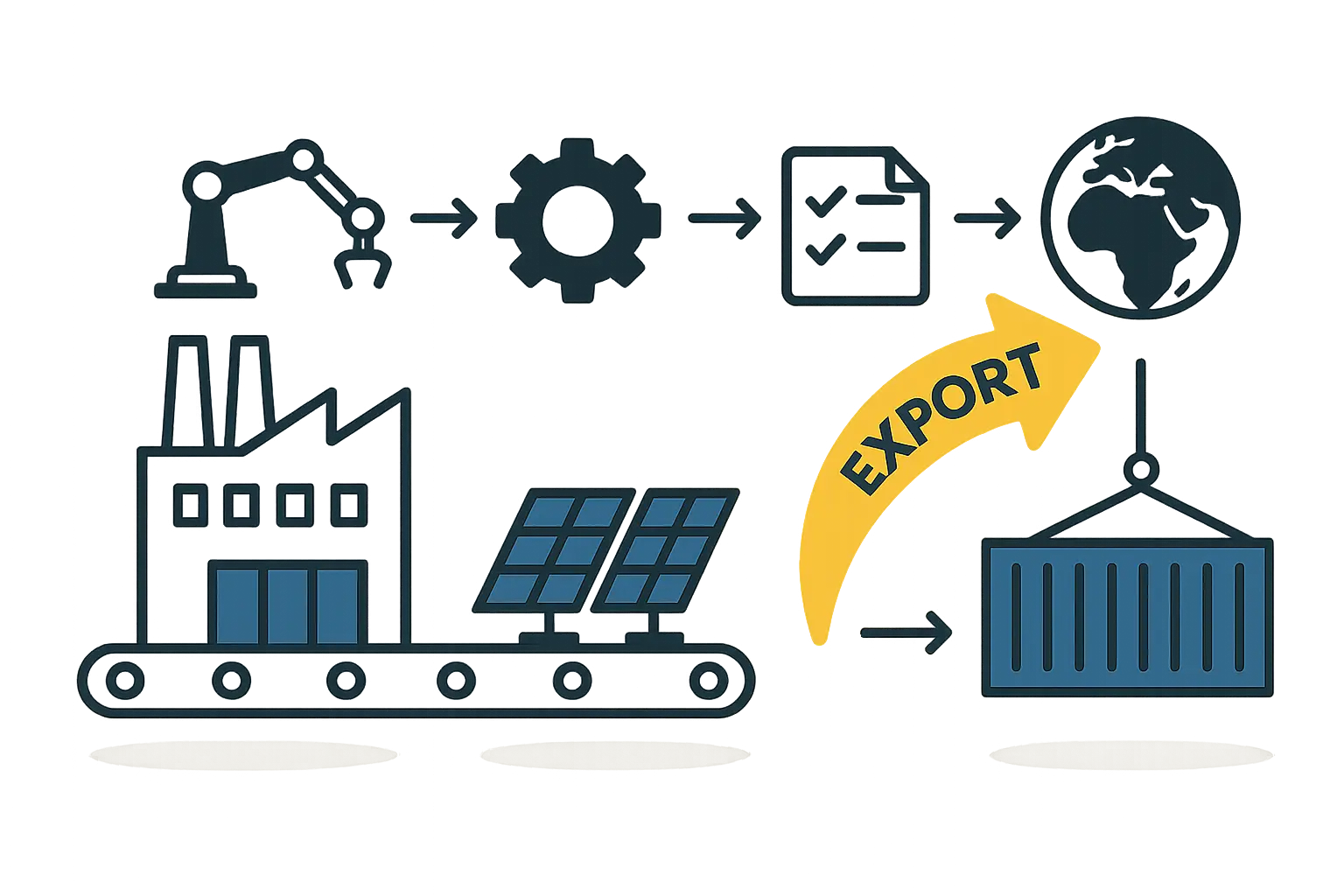

Beyond Borders: Export Potential within the East African Community (EAC)

While the domestic market in Kenya is compelling, the opportunity expands significantly across the region. Kenya is a key member of the East African Community (EAC), a common market that includes Tanzania, Uganda, Rwanda, Burundi, South Sudan, and the Democratic Republic of Congo.

Many of these neighboring countries share a similar energy profile, defined by growing populations and economies, limited grid infrastructure, and high levels of solar irradiation.

A manufacturing facility based in Kenya is strategically positioned to serve as an export hub for the entire EAC region. Producing modules locally can offer significant advantages over relying on international imports, including reduced shipping times, lower logistical costs, and the ability to provide regionally-focused customer support. This approach transforms a national business case into a powerful regional one.

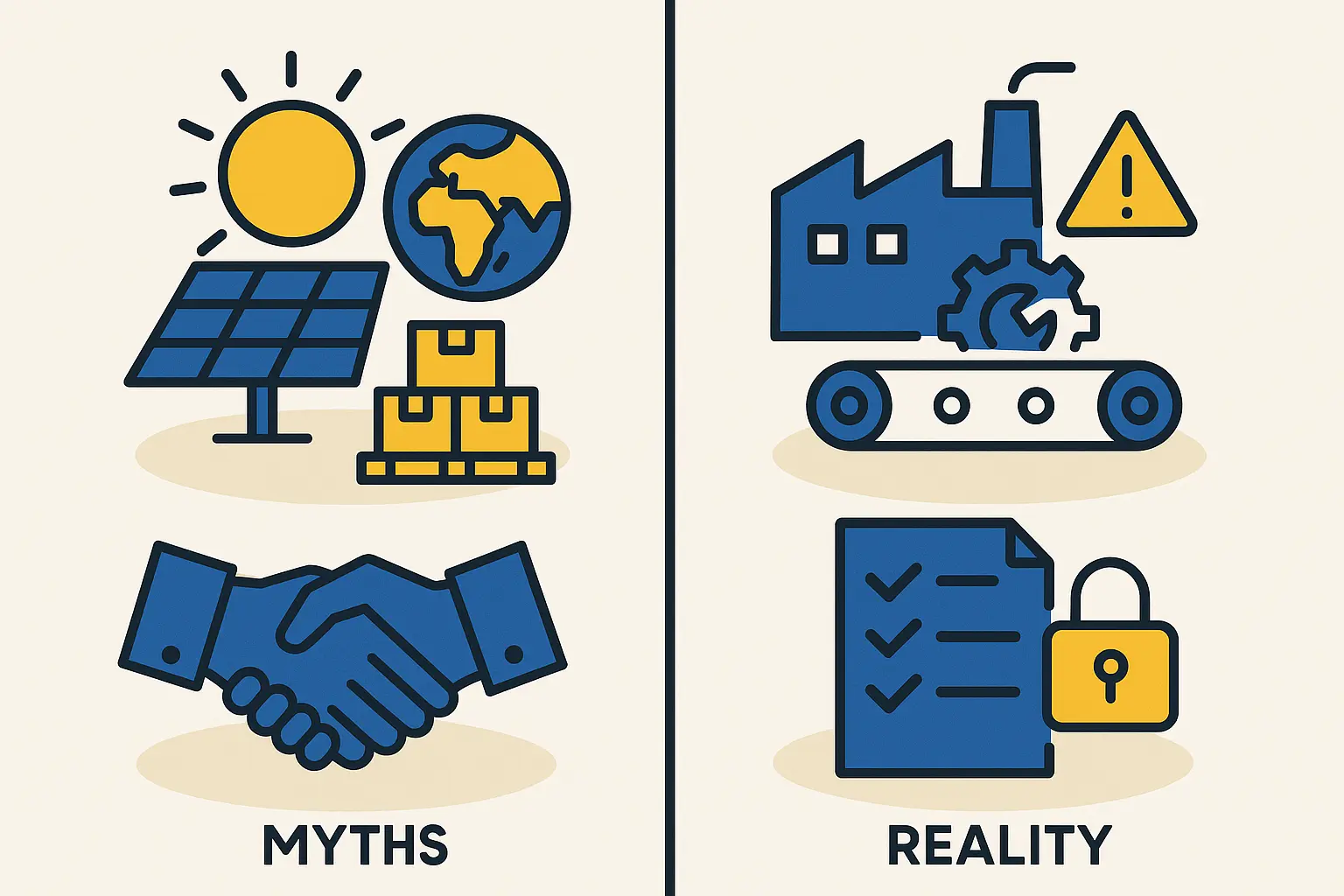

The Case for Local Production: Bridging the Quality Gap

Currently, the Kenyan solar market is predominantly supplied by imported modules from Asia and Europe. While this has met initial demand, it also presents a distinct challenge and an opportunity: inconsistent quality. The market is often flooded with panels of varying standards, making it difficult for consumers and businesses to secure reliable, long-lasting products.

A local factory can address this quality gap head-on. By implementing internationally recognized quality control standards, a local manufacturer can build a reputation for reliability and trust. Properly understanding solar panel certifications is not just a technical detail; it becomes a powerful market differentiator.

A local facility also allows for greater control over the production process, from sourcing raw materials to final assembly. This ensures the final product is tailored to withstand local environmental conditions, such as high temperatures and dust, which can impact panel performance and longevity. Achieving these quality benchmarks begins with the factory setup itself—requiring both careful selection of the key machinery for a solar panel production line and a clear understanding of setting up a solar module factory.

Frequently Asked Questions (FAQ)

What is the primary driver of solar demand in Kenya?

Demand is driven by two main segments: the need for rural electrification for households without grid access, and the Commercial & Industrial (C&I) sector’s search for reliable power to avoid grid disruptions and lower high electricity costs.

Is it difficult to compete with cheaper imported panels?

While low-cost imports pose a challenge, they also create an opportunity. Many consumers and businesses have experienced issues with low-quality, unreliable panels. A local manufacturer focused on producing certified, high-quality modules can compete effectively by offering a more durable, trustworthy product backed by better local support and warranty fulfillment.

What government incentives support solar manufacturing?

The Kenyan government offers significant incentives, including exemptions from Value Added Tax (VAT) and import duties for renewable energy equipment and components. This policy lowers the capital expenditure required to set up a factory and reduces the final cost of the manufactured modules, making them more competitive.

Understanding these demand dynamics is a critical first step in assessing the viability of a solar manufacturing venture. A strong domestic market, combined with significant regional export potential and the opportunity to supply high-quality products, creates a compelling business case.

This analysis is part of a larger framework for entering the solar industry. For a complete overview covering investment, technology, and operational planning, our comprehensive report on Solar Manufacturing Opportunities in Kenya offers a deeper level of detail.