Many entrepreneurs envision a state-of-the-art solar factory, complete with automated machinery and pristine production floors. The long-term success of such an enterprise, however, depends less on the machines themselves and more on what happens outside the factory walls—sourcing materials and developing a skilled workforce.

In a market as dynamic as Kenya’s, understanding these two pillars is fundamental to building a resilient and profitable solar manufacturing business. This article explores the practical realities of establishing a supply chain in Kenya, from the availability of labor and the critical need for training to the logistics of sourcing raw materials and distributing finished panels across the region.

The Workforce Advantage: Tapping into Kenya’s Human Capital

A factory’s greatest asset is its people. For an investor entering the Kenyan market, the human resource landscape presents both a significant opportunity and a challenge that requires strategic planning.

Analyzing the Labor Pool: A Young and Eager Workforce

Kenya has a significant demographic advantage. With roughly 75% of its population under 35, the country has a vast and energetic labor pool. This youthful demographic is generally literate, adaptable, and increasingly digitally savvy—a strong foundation for modern factory operations.

For a semi-automated solar module assembly line, the initial staffing requirements are relatively modest. A typical 20–50 MW facility can often start operations with a team of 25 to 35 employees, including operators, technicians, and administrative staff. The challenge isn’t just finding willing candidates; it’s transforming their potential into specialized, industry-specific expertise.

Bridging the Skills Gap: The Need for Specialized Training

While Kenya has an abundant workforce, direct experience in photovoltaic manufacturing is scarce—a common scenario in emerging solar markets. Instead of searching for nonexistent experience, the key is to implement a structured training program.

Although the country’s network of Technical and Vocational Education and Training (TVET) institutions offers a solid baseline of technical aptitude, the specific skills needed to operate machines like solar cell stringers, laminators, and testers must be taught through targeted programs.

Based on experience from J.v.G. turnkey projects, a successful approach involves:

-

Hiring for Attitude and Aptitude: Focus on candidates who demonstrate technical curiosity, attention to detail, and a capacity for learning.

-

On-Site Expert Training: Bringing in an experienced engineer for the initial setup and commissioning phase is crucial for providing hands-on training to the first cohort of operators and supervisors.

-

Structured E-Learning: Supplementing practical training with structured educational materials ensures the team understands the ‘why’ behind the ‘how.’ The pvknowhow.com platform provides foundational courses designed for professionals and their teams who are new to the industry.

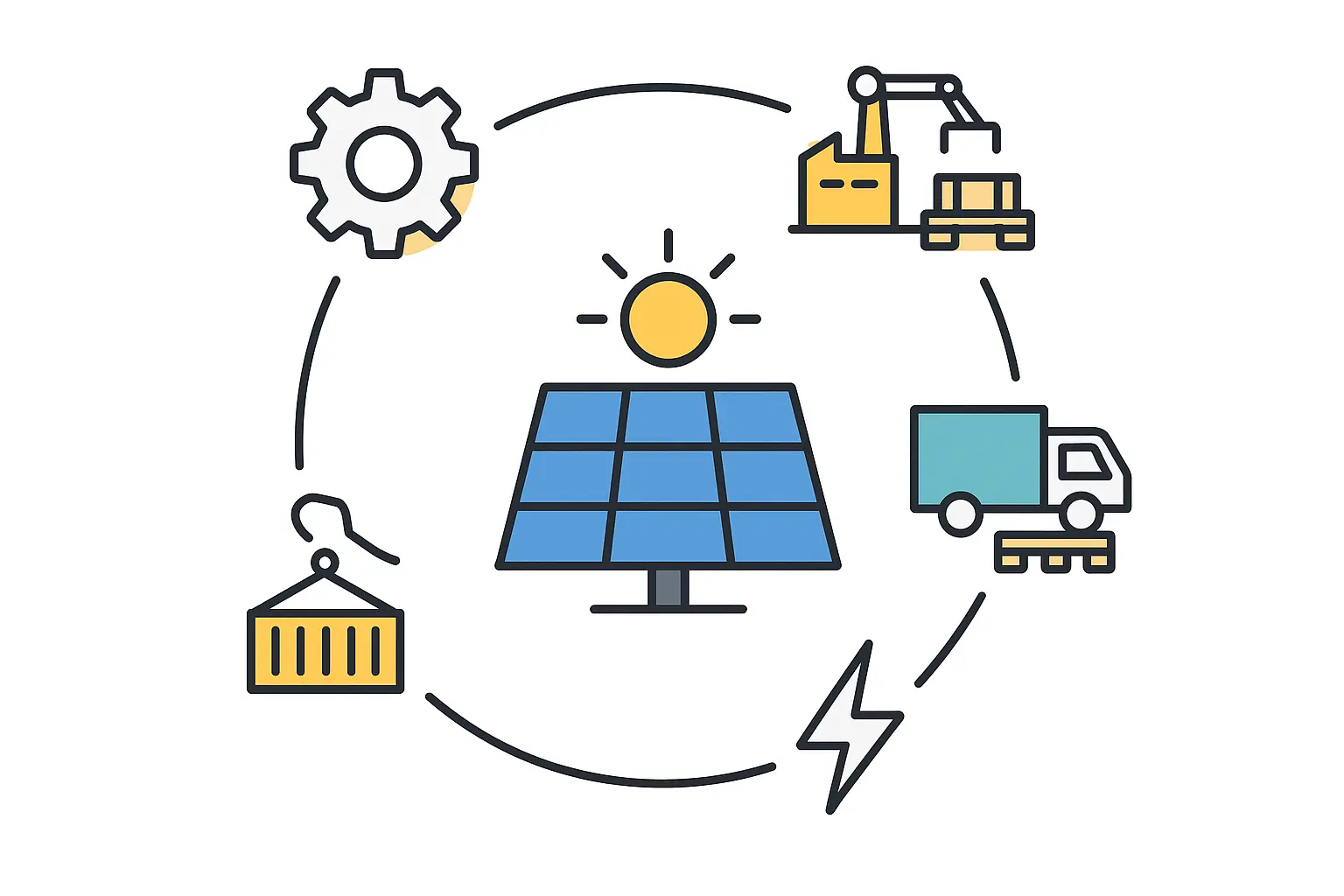

Navigating the Logistical Landscape

A smooth, predictable supply chain is the lifeblood of any manufacturing operation. In Kenya, this means effectively managing both inbound logistics for raw materials and outbound logistics for finished products. The government’s Vision 2030 initiative has led to significant investments in infrastructure, creating a more favorable environment for such ventures.

Inbound Logistics: Sourcing Raw Materials

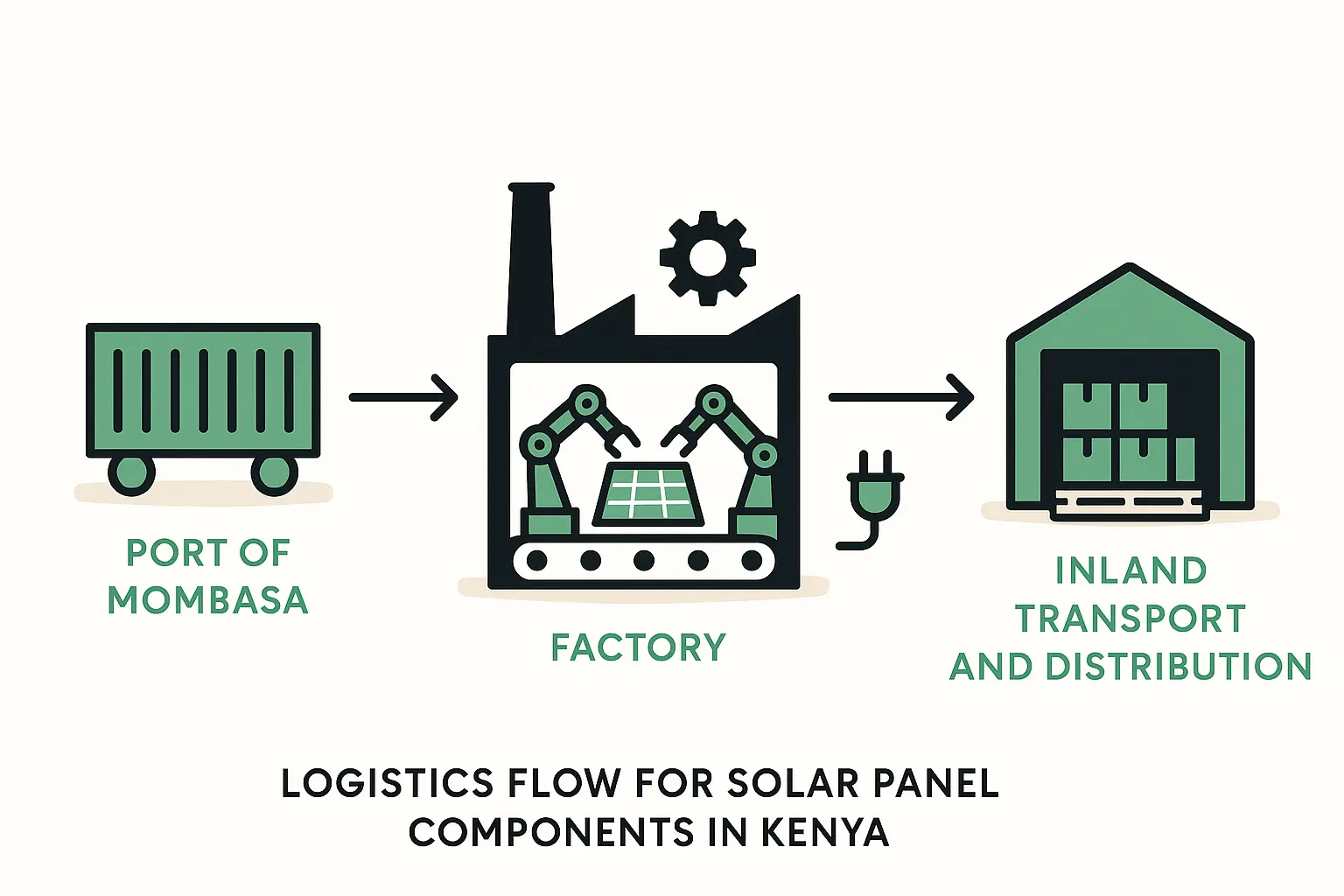

Most raw materials for solar panel assembly—like solar cells, EVA film, backsheets, and junction boxes—will need to be imported. The Port of Mombasa serves as the primary gateway not just for Kenya, but for much of East Africa.

Key considerations for inbound logistics include:

-

Port Efficiency: The Port of Mombasa has undergone significant expansion, improving its capacity. However, navigating customs procedures still requires expertise.

-

Customs and Clearing: Engaging a reliable customs clearing agent is not just a recommendation—it’s a business necessity. A good agent can prevent costly delays, demurrage charges, and administrative hurdles.

-

Inland Transportation: Once cleared, materials must be transported from the port to the factory. The cost, time, and security of this inland transit are critical parts of financial planning. Understanding the full solar panel manufacturing process helps in planning the phased arrival of these essential materials.

Outbound Logistics: Distributing Finished Modules

With a growing domestic and regional demand for clean energy, driven by initiatives like the Kenya National Electrification Strategy (KNES), the market for locally produced panels is strong.

Effective outbound logistics involves:

-

Road Network: Major corridors are generally well-maintained, but reaching rural or remote areas—where demand for off-grid solutions is highest—can present challenges.

-

Regional Export: Kenya’s strategic location and membership in the East African Community (EAC) provide preferential access to markets in Uganda, Tanzania, Rwanda, and beyond.

-

Packaging and Handling: Ensuring panels are securely packaged for transit is vital to prevent damage and maintain product quality upon arrival.

These logistical considerations directly impact the overall investment in a factory. A comprehensive business plan must account for shipping costs, import duties, and distribution networks.

Key Considerations for a Resilient Supply Chain

A successful operation goes beyond simply moving goods; it requires building a robust system that can withstand unforeseen challenges.

The Role of Local Partnerships

Building relationships with local logistics providers, transporters, and business associations can provide invaluable market intelligence and operational support. These partners understand the local context and can help navigate challenges that may not be apparent to an outside investor.

Quality Control Across the Chain

Quality control doesn’t begin on the production line. It starts with inspecting incoming raw materials and ends with the safe delivery of the final product. Implementing clear quality checkpoints at each stage of the supply chain is essential for protecting a brand’s reputation.

Frequently Asked Questions (FAQ)

Q: Do I need to find employees with prior solar manufacturing experience in Kenya?

A: No, it’s highly unlikely you’ll find a large pool of candidates with this specific experience. The standard and most effective approach is to hire for general technical aptitude and provide specialized, on-site training during the factory commissioning phase.

Q: How long does it typically take for raw materials to clear customs in Mombasa?

A: This can vary significantly depending on your documentation and the efficiency of your clearing agent. A well-managed process can take a few days, while complications can lead to weeks of delays. It’s wise to build a buffer into your production schedule.

Q: Is it better to locate a factory near the port or closer to end markets?

A: This is a key strategic decision. Locating near Mombasa simplifies inbound logistics for raw materials, while a location near Nairobi or another major hub may simplify outbound distribution. The choice depends on a detailed analysis of transport costs and target markets.

Q: Can local universities or TVETs provide the necessary training?

A: TVETs can provide a strong foundation in electrical or mechanical principles, but they do not offer curricula specific to PV module assembly. They are a source of talent to be trained, not a source of ready-made experts.

Conclusion: Turning Challenges into a Competitive Edge

Establishing a solar manufacturing operation in Kenya requires a clear understanding of the on-the-ground realities of its workforce and logistics. The country’s young population and strategic infrastructure investments present a compelling opportunity.

Success doesn’t hinge on finding a perfect, ready-made system. Instead, it comes from systematically building one by investing in structured training for a motivated local workforce and developing robust logistical processes with reliable local partners.

By addressing these operational factors from the outset, an entrepreneur can build a truly sustainable and competitive manufacturing enterprise. For those considering this venture, the next step is to integrate these insights into a comprehensive business plan that clarifies the approach to setting up a solar factory in Kenya.