A solar panel is more than an assembly of advanced components; it’s the culmination of a complex logistical puzzle. For an entrepreneur planning to establish a solar module factory in Kuwait, solving this puzzle is a critical first step. The nation’s Vision 2035, which targets 15% of its energy from renewable sources by 2030, promises a substantial domestic market. Success, however, depends not just on production technology but also on a robust strategy for sourcing raw materials.

This article breaks down the two pillars of the supply chain for a new solar factory in Kuwait: importing critical international components and cultivating a resilient local supply network. Understanding these logistics is foundational to learning how to start a solar panel manufacturing business.

The Global vs. Local Dilemma: A Strategic Overview

Every prospective manufacturer faces a fundamental choice: should the factory import all necessary materials, or should it seek to develop local sources?

Import-Heavy Model

This approach provides access to a global market of specialized, high-quality component suppliers. It’s often faster to initiate, as it leverages existing international supply chains. However, this model exposes the business to currency fluctuations, shipping delays, and geopolitical risks.

Local Sourcing Model

Developing local suppliers reduces transportation costs, shortens lead times, and builds resilience against global disruptions, all while aligning with national economic development goals. The primary challenge is ensuring local sources can meet the stringent quality and volume requirements of solar module manufacturing.

A successful strategy for Kuwait will likely be a hybrid, relying on imports for highly specialized materials while strategically developing local capacity for others.

Importing Key Components: The Lifeline of a New Factory

Initially, at least, certain high-technology components are best sourced from established international leaders in Asia, Europe, and North America.

What to Import: The Core Bill of Materials

The core of a solar panel consists of materials that require immense capital investment and specialized technical expertise to produce. For a new facility in Kuwait, these will almost certainly be imports.

Key imported materials include:

- Solar Cells: The most critical components, converting sunlight into electricity. They are manufactured in highly controlled environments.

- Silicon Wafers: For manufacturers who plan to produce their own cells (a more advanced setup), these ultra-thin silicon slices are the base material.

- EVA (Ethylene Vinyl Acetate) Film: This encapsulant material laminates the components together, protecting the cells from moisture and impact.

- Backsheets: The rearmost layer of the panel, providing mechanical protection and electrical insulation.

Kuwait’s Maritime Gateways: Shuwaikh vs. Shuaiba Port

Since the majority of these materials will arrive by sea, the choice of port is a key logistical decision.

- Shuwaikh Port: Located close to Kuwait City, it is the country’s primary commercial port. Its proximity to the capital can mean faster access to customs brokers and administrative offices, though it can face congestion and has limitations on vessel size.

- Shuaiba Port: Situated south of Kuwait City, this is Kuwait’s main industrial port. It is better equipped to handle large volumes of industrial cargo and is located near designated industrial zones, which could reduce inland transportation costs if the factory is located nearby.

Key factors in selecting a port include shipping line availability, handling charges, storage facilities, and the efficiency of customs clearance procedures.

The Supply Chain in Action: From Port to Production Line

The journey of raw materials doesn’t end at the port. A well-defined inland logistics process is essential for uninterrupted production.

The process breaks down into several stages:

- Customs Clearance: Accurate documentation compliant with Kuwaiti regulations is critical for avoiding costly delays. Working with an experienced local customs broker is a wise move.

- Warehousing: Once cleared, materials must be transported to a secure, climate-controlled warehouse. Components like EVA film are particularly sensitive to temperature and humidity.

- Inventory Management: A robust system is needed to track stock levels and ensure the production line is consistently supplied with materials.

These logistical steps are a significant part of the overall solar panel manufacturing plant cost and must be factored into any serious business plan.

Building a Resilient Local Supply Chain: The Long-Term Opportunity

While high-tech cells must be imported, Kuwait’s industrial base offers significant potential for localizing other parts of the supply chain. This is not just a cost-saving measure but a strategic advantage.

Low-Hanging Fruit: What Can Be Sourced Locally?

Several key components could be manufactured or sourced within Kuwait by leveraging existing industries.

- Aluminum Frames: Kuwait has a well-established aluminum extrusion industry. Sourcing frames locally can drastically reduce shipping costs and allows for designs tailored to regional conditions.

- Glass: While specialized low-iron, tempered solar glass is required, Kuwait’s existing glass manufacturers could potentially adapt their production to meet these specifications. This offers a major opportunity to reduce reliance on fragile and heavy imports.

- Junction Boxes and Cables: These electrical components are less complex to manufacture. Local assembly or production is a feasible goal that taps into the local electrical supply industry.

The Strategic Advantage of Local Sourcing

Developing these local capabilities provides numerous benefits. It reduces lead times, strengthens the local economy in line with Vision 2035, and gives manufacturers greater control over the final product.

Most importantly, it allows for the creation of solar modules specifically designed for Kuwait’s challenging climate. High temperatures, which regularly exceed 50°C, and frequent sandstorms place unique stresses on solar panels. A local supply chain enables the production of modules with robust frames, specialized glass coatings, and heat-resistant components, creating a product superior to generic imported panels.

A Note on Specialized Equipment

The initial setup of the factory itself involves a significant logistical operation: importing production machinery. The list of machines required for solar panel manufacturing, from cell stringers to laminators and testers, is a major one-time import project. Experience from J.v.G. turnkey projects shows that coordinating the shipment and installation of this equipment requires meticulous planning months in advance.

Frequently Asked Questions (FAQ)

How long does it typically take to clear solar components through Kuwaiti customs?

While times can vary, it’s wise to budget for two to four weeks for customs clearance. A smooth process depends on ensuring all shipping documents, certificates of origin, and technical specifications are accurate and submitted correctly through a reliable local agent.

Are there specific import duties on solar raw materials in Kuwait?

As a member of the Gulf Cooperation Council (GCC), Kuwait applies the GCC Common Customs Law. Many goods are subject to a standard 5% duty, but governments in the region often provide exemptions for materials used in strategic sectors like renewable energy. Consulting with a local customs authority or broker is essential for the most current regulations.

Is it more cost-effective to import finished panels or manufacture locally in Kuwait?

Importing finished panels offers a lower initial investment and simpler logistics. However, local manufacturing provides significant long-term advantages, including the ability to customize panels for the local climate, reduced shipping costs, and avoidance of import tariffs on finished goods. It also contributes to local job creation, which aligns with national strategic goals.

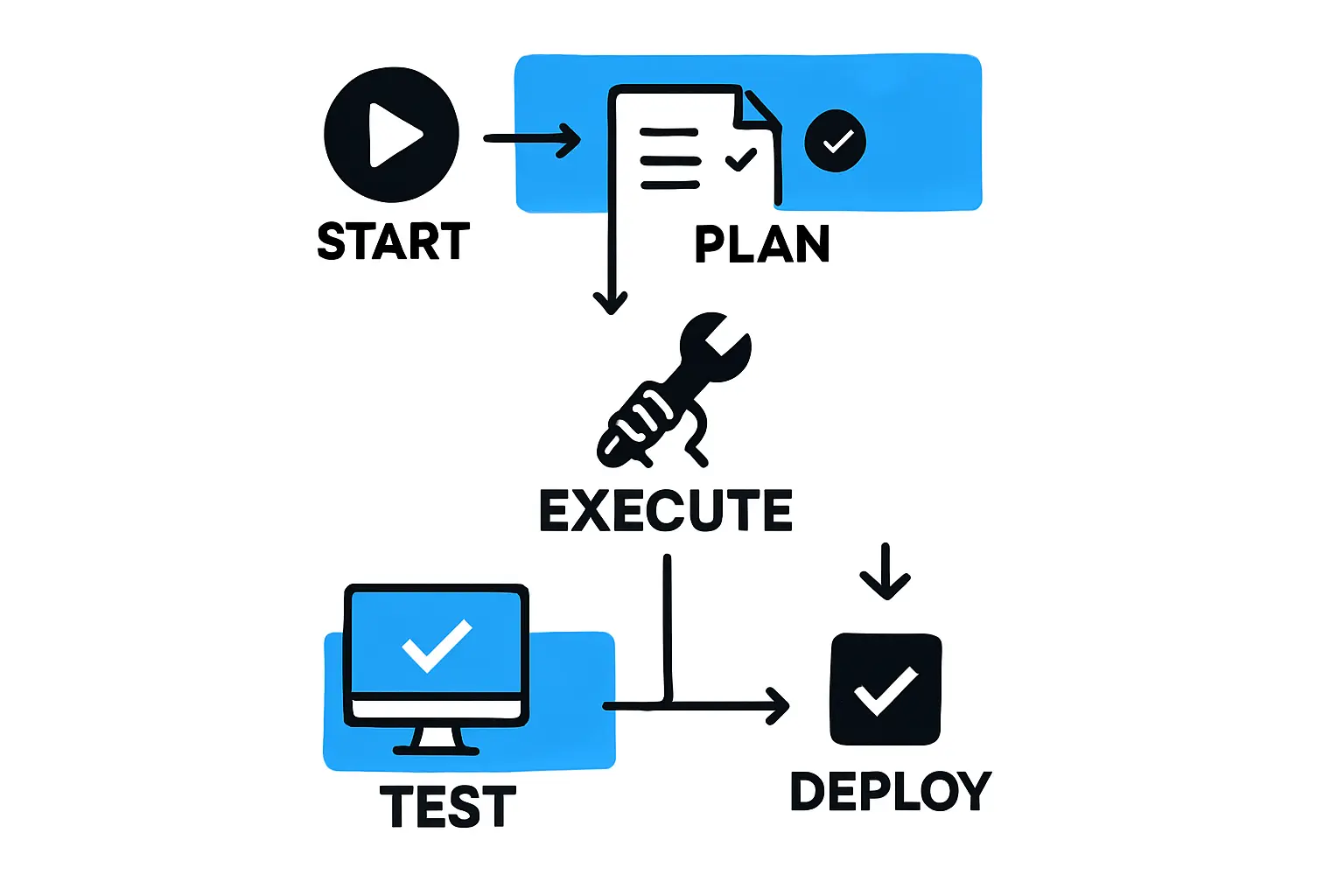

What is the first step in establishing a reliable supply chain for a new factory?

The first step is a dual-track process of supplier qualification and logistics planning. This involves thoroughly vetting potential international suppliers for quality and reliability while simultaneously engaging with Kuwait-based freight forwarders and customs agents to map out the entire logistical chain, from the foreign port to the factory floor.

Conclusion: Your Strategic Next Steps

A successful solar manufacturing venture in Kuwait depends on a thoughtful, hybrid supply chain strategy. This approach means leveraging the global market for high-tech components like solar cells while actively cultivating local suppliers for materials such as aluminum frames and glass.

This strategy lets a new enterprise not only manage costs but also build a resilient operation that produces modules optimized for the demanding regional climate. Understanding these logistical complexities is the starting point. The next is to translate this knowledge into a comprehensive business plan, a detailed factory layout, and a sound financial model that accounts for every link in the supply chain.