Imagine the final quality control check on your first pallet of newly manufactured solar modules. The machines are running smoothly, your team is performing well, and the facility is poised for success. Suddenly, the lights flicker and die. The entire production line grinds to a halt.

A power outage like this isn’t just an inconvenience for a solar module factory—it’s a critical operational and financial risk. In a location like Lesotho, understanding and mitigating this risk is fundamental to building a resilient business.

While Lesotho boasts some of the highest solar irradiation levels in the world, its national power grid tells a different story. For an entrepreneur planning to establish a solar factory here, a clear-eyed assessment of the electrical infrastructure is not just a technical detail—it is the cornerstone of a viable business strategy.

The Reality of Lesotho’s National Grid

Effective planning begins with understanding the context. Lesotho’s energy situation is defined by a heavy dependence on external sources, directly impacting the stability and reliability of its power supply.

A Story of Dependency

Lesotho’s grid is almost entirely powered by electricity imported from South Africa’s state-owned utility, Eskom. This reliance creates a direct link between Lesotho’s power availability and South Africa’s well-publicized energy challenges, including frequent load-shedding (planned, rolling blackouts). When Eskom implements load-shedding to protect its own grid, Lesotho experiences the direct consequences.

This creates a structural vulnerability for any industrial operation. While the country has immense potential for renewable energy, its current domestic generation—primarily from the Lesotho Highlands Water Project (LHWP)—is largely exported and does not serve the local grid. This leaves local industries exposed to the instabilities of an imported power supply.

Why Consistent Power is Non-Negotiable in Solar Manufacturing

A brief power interruption can trigger a cascade of problems on a solar module production line. Certain stages of the manufacturing process are highly sensitive to shutdowns and cannot simply be paused and restarted without serious consequences.

-

Lamination and Curing: The lamination process involves heating and pressing materials together under a vacuum to encapsulate the solar cells. If power is lost mid-cycle, the entire batch of modules inside the laminator can be ruined, leading to significant material waste and financial loss.

-

Machine Calibration: Automated equipment, such as cell stringers and testers, requires precise calibration. A sudden shutdown can cause these machines to lose their settings, requiring downtime for recalibration by skilled technicians.

-

Production Targets: Unplanned downtime directly impacts output, leading to missed production targets, delayed shipments, and potential contractual penalties.

The financial impact of a single hour of lost production can often exceed the daily cost of maintaining a reliable backup power system.

Evaluating On-Site Power Solutions

Given the realities of Lesotho’s grid, an on-site backup power source is not an optional extra; it is an essential piece of infrastructure. The two primary options for an investor are diesel generators and a captive solar power system with battery storage. The choice between them involves a trade-off between initial investment and long-term operational costs.

Option 1: Diesel Generators

Diesel generators are a conventional and well-understood solution for backup power. They offer a reliable and immediate source of electricity during a grid outage.

Advantages: Lower initial capital expenditure (CAPEX) compared to a solar-plus-storage system. The technology is mature, and local maintenance expertise is generally available.

Disadvantages: High and volatile operational expenditure (OPEX) due to fluctuating diesel fuel costs. Regular maintenance is required. Generators also produce noise and emissions, undermining the clean-energy brand of a solar manufacturer.

Option 2: Captive Solar Power System with Battery Storage

A captive solar system involves installing a private solar power plant on-site, often on the factory roof or adjacent land, coupled with a battery energy storage system (BESS). This system can power the facility during the day, store excess energy, and provide seamless backup during a grid failure.

Advantages: Drastically lower and more predictable long-term operational costs, as the ‘fuel’ (sunlight) is free. It provides energy independence and insulates the business from grid instability and rising electricity tariffs. It also powerfully reinforces the company’s commitment to renewable energy.

Disadvantages: Significantly higher initial capital investment. Requires physical space for the solar array and battery system.

A Framework for Decision-Making

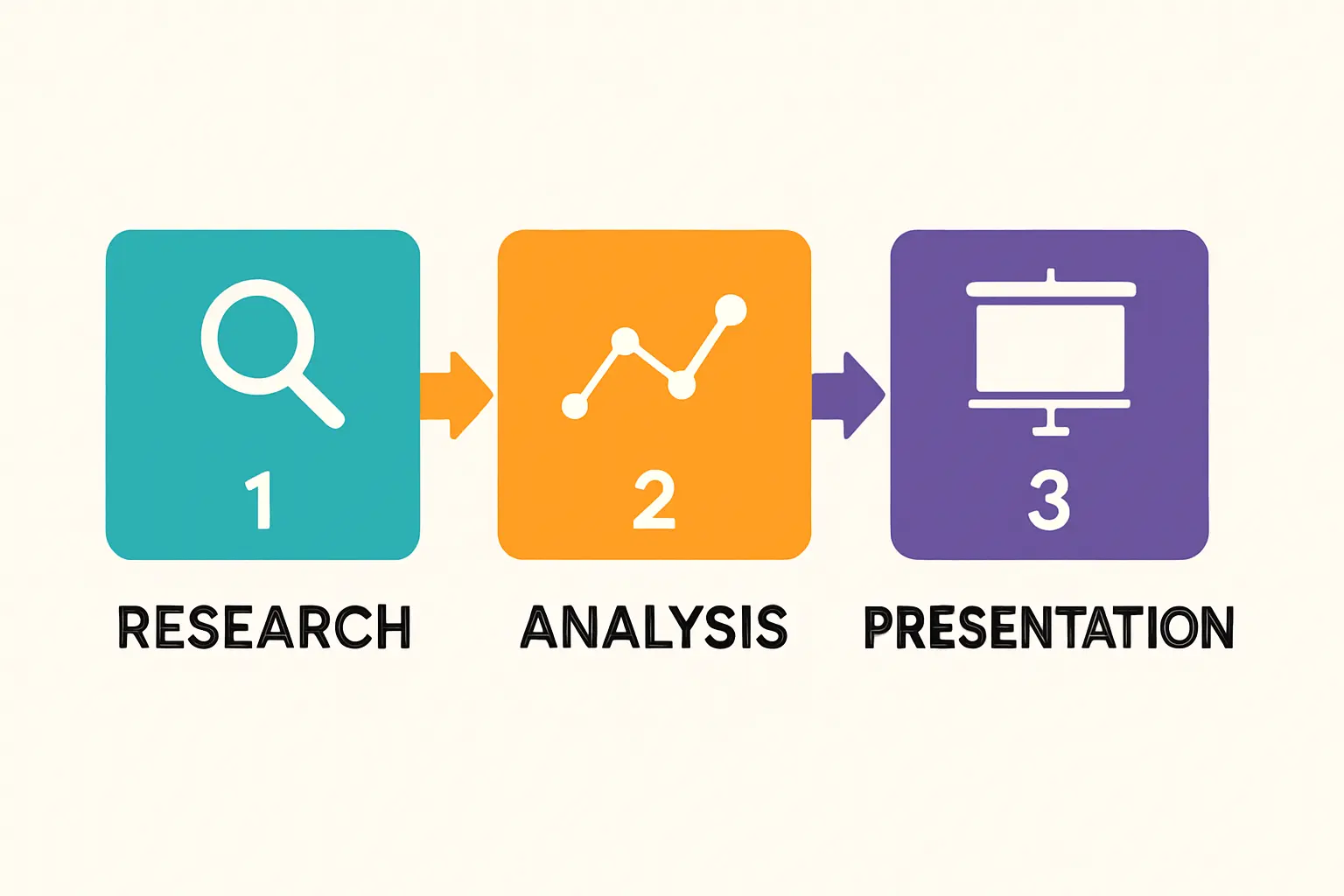

Choosing the right power solution requires a structured analysis rooted in the specific needs of the factory. A comprehensive solar panel manufacturing business plan must include a detailed section on energy security.

-

Calculate Your Total Power Demand: Determine the peak power consumption of your entire solar module production line. This figure, measured in kilowatts (kW) or megawatts (MW), is the foundation for sizing any backup system.

-

Quantify the Risk of Downtime: Analyze historical data on load-shedding and power outages in your specific location within Lesotho. Estimate the potential number of downtime hours per year. This analysis helps you calculate the potential revenue loss and material waste, providing a clear financial justification for investing in a backup solution.

-

Model the Total Cost of Ownership (TCO): A simple comparison of initial purchase prices is insufficient. A TCO analysis over a 10- or 20-year period paints a more accurate picture. For generators, include initial purchase, installation, fuel consumption, regular maintenance, and potential engine overhauls. For captive solar, include panels, inverters, batteries, installation, and minimal maintenance costs. Factor in the savings from not purchasing grid electricity.

This detailed financial modeling is a critical part of determining the overall cost to start a solar panel manufacturing company. Based on J.v.G. Technology GmbH’s experience with turnkey projects in emerging markets, clients who perform this TCO analysis often find that a captive solar plant, despite its higher upfront cost, offers a superior long-term return on investment.

Frequently Asked Questions (FAQ)

Q: Can a solar factory operate completely off-grid in Lesotho?

A: While technically possible with a sufficiently large solar array and battery system, it is often more practical and cost-effective to remain grid-connected. The grid can serve as a backup to the captive solar plant, and any excess solar generation could potentially be sold back to the grid, depending on local regulations. The primary goal is uninterrupted operation, not complete grid independence.

Q: How much space is needed for a captive solar power system?

A: The space requirement depends on the factory’s energy consumption. A common approach is to use the factory’s rooftop, which is often extensive and ideal for solar panel installation. For a typical 20-50 MW per year module factory, the rooftop area is often sufficient to house a solar plant that can significantly offset its power consumption.

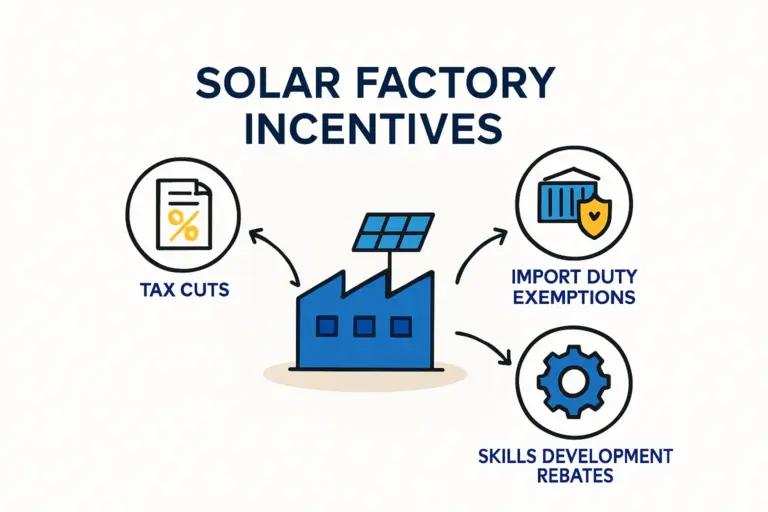

Q: Are there government incentives in Lesotho for installing a captive solar plant?

A: The Government of Lesotho has expressed a strong commitment to attracting investment in the renewable energy sector. Investors should conduct thorough due diligence and engage with local investment promotion agencies to explore potential incentives, tax benefits, or streamlined permitting processes for projects that contribute to the country’s energy security and green-tech ambitions.

Conclusion: Turning a Challenge into a Strategic Advantage

The unstable power grid in Lesotho presents a significant operational challenge for any prospective solar module manufacturer. However, by acknowledging this reality and planning for it proactively, an entrepreneur can turn a potential weakness into a source of strength.

Investing in a robust on-site power solution—whether diesel or, more strategically, a captive solar-plus-storage system—is not just an operational expense. It is a fundamental investment in production continuity, financial stability, and long-term business resilience. By ensuring your factory can run uninterrupted, you not only protect your investment but also build a more competitive and sustainable enterprise in one of the world’s most promising solar markets.