An entrepreneur envisions a state-of-the-art manufacturing facility in the heart of Europe, selecting Liechtenstein for its economic stability, central location, and favorable business environment. The plan is solid, the investment secured, and the technology chosen. Yet a critical question is often underestimated: how do you efficiently supply a factory with raw materials from Asia, the Americas, or even neighboring countries when it’s located in a country with no seaport?

This scenario highlights a common challenge for investors considering landlocked locations. The logistical framework for such an operation is no mere detail—it’s a foundational pillar of the business plan. A well-designed supply chain can become a significant competitive advantage; a poorly planned one can lead to costly delays and operational inefficiencies. This article explores the logistical challenges and strategic solutions for sourcing raw materials to a plant in Liechtenstein, offering a model for any landlocked industrial project.

Understanding Liechtenstein’s Unique Logistical Position

To grasp the supply chain dynamics, one must first understand Liechtenstein’s unique geographic and economic situation. Nestled between Switzerland and Austria, it is one of only two doubly landlocked countries in the world. Its deep economic integration with its neighbors, however, creates a distinct set of rules for commerce.

Key factors include:

-

The Swiss Customs Union: Since 1924, Liechtenstein has been part of a customs union with Switzerland. This means goods move between the two countries with minimal friction, and they share a common external tariff policy. For practical purposes, a shipment to Liechtenstein is treated as a shipment to Switzerland.

-

European Economic Area (EEA) Membership: As an EEA member, Liechtenstein enjoys access to the EU’s single market, which facilitates the movement of goods from member states. Because it is not in the EU Customs Union, however, customs formalities still apply, albeit in a simplified form.

-

Proximity to Major Transport Arteries: While landlocked, the country is situated near major European transport corridors. The Rhine Valley provides a crucial north-south route, and Alpine road and rail tunnels like the Gotthard Base Tunnel connect the region to major seaports. Research indicates that over 60% of containerized freight from Asia destined for this region arrives via the northern ports of Rotterdam and Hamburg.

This combination of factors means that while goods cannot arrive by sea, they can be transported efficiently overland from the world’s largest ports. The challenge lies in managing the transition from sea to land and navigating the specific customs frameworks.

Key Challenges in Sourcing Raw Materials

For a solar module factory, raw materials like solar glass, aluminum frames, and EVA encapsulant are often sourced globally. Any business plan must therefore account for several inbound logistical hurdles.

Multi-Modal Transportation Complexity

A typical shipment from a supplier in Asia will arrive at a European seaport like Rotterdam. From there, it must be transferred to a train or truck for its journey to Liechtenstein. This “modal shift” introduces potential points of failure:

-

Delays at Port: Congestion, labor strikes, or administrative backlogs can hold up the transfer of containers.

-

Coordination: Seamless communication between the ocean freight carrier, the port terminal operator, and the inland transport provider is critical.

-

Cost Management: Each leg of the journey—ocean, port handling, and inland transport—has its own costs that must be carefully calculated and optimized. For a standard 40-foot container, inland transport from Rotterdam to the Swiss/Liechtenstein border can account for 25-35% of the total shipping cost.

Customs and Border Formalities

Here, Liechtenstein’s unique status becomes most apparent. The clearance process differs significantly depending on the origin of the goods:

-

Goods from the EU: While shipments from the EU benefit from the EEA agreement, they still must be declared for customs. The process is streamlined but requires correct documentation (e.g., a T2 document) to prove EU origin and avoid tariffs.

-

Goods from Outside the EU/EFTA (e.g., Asia): These are subject to Swiss external tariffs and import VAT upon entry into the Swiss-Liechtenstein customs territory. This clearance can happen at the Swiss border (e.g., Basel) or at an inland customs office. Inaccurate paperwork is a primary cause of delays, capable of holding up critical materials for days.

A well-structured plan requires a deep understanding of these distinct processes. Investors can find more information by reading about Navigating Import Duties and Certifications for Solar Manufacturing.

Last-Mile Delivery

The final leg of the journey, from a main transport hub to the factory floor, presents its own challenges. Navigating local Alpine roads with oversized trucks carrying sensitive materials like large sheets of solar glass requires specialized carriers and careful route planning.

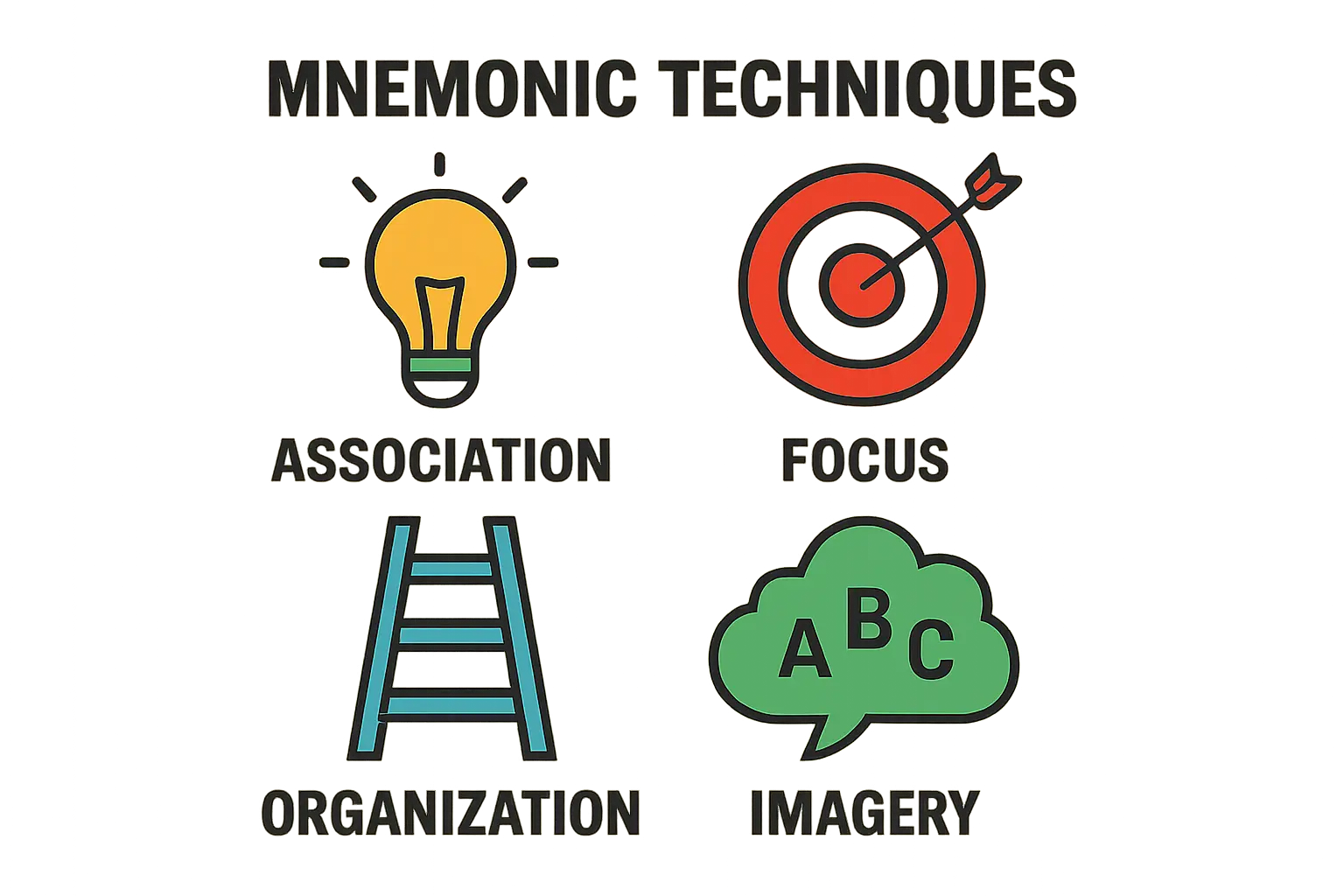

Strategic Solutions for an Efficient Supply Chain

With proactive planning, these challenges are entirely manageable. The goal is to build a supply chain that is resilient, predictable, and cost-effective.

1. Route and Port Optimization

Choosing the right seaport is a critical strategic decision. While Northern European ports like Rotterdam and Hamburg are the most common, southern ports like Genoa or La Spezia in Italy can offer advantages for shipments from Asia, potentially shortening sea transit times.

A thorough analysis should compare:

-

Total Transit Time: Sea voyage plus inland rail or road time.

-

Total Cost: Including ocean freight, port fees, customs brokerage, and inland transport.

-

Reliability: The frequency of rail connections and the historical performance of the transport corridors.

For example, the rail freight connection through the Gotthard Base Tunnel can be up to 48 hours faster and more reliable than road transport, especially during adverse winter weather.

2. Strategic Supplier Selection

The complexity of intercontinental logistics creates a strong incentive to source materials from closer suppliers where feasible. Sourcing aluminum frames from Germany or specialty chemicals from Austria, for instance, dramatically simplifies the logistical equation by reducing transit times, lowering transportation costs, and minimizing customs-related risks. A detailed understanding of the necessary components is a prerequisite, as outlined in A Comprehensive Guide to Solar Panel Raw Materials.

3. Partnership with Specialized Logistics Providers

Managing this complex network in-house without prior experience is a significant risk. Partnering with a freight forwarder or third-party logistics (3PL) provider specializing in the Swiss/Liechtenstein economic area is essential. These partners have established relationships with carriers, customs brokers, and port authorities. They can manage all documentation, troubleshoot delays, and provide end-to-end visibility of a shipment. This single point of contact is invaluable for a new manufacturing venture.

A Case Study in Planning: The J.v.G. Approach

Experience from J.v.G. turnkey projects shows that logistical planning must be integrated from the earliest stages of a project’s feasibility study. For one client, an entrepreneur from the Middle East establishing a 50 MW plant in the region, the initial plan was to source all materials from Asia via the nearest southern port to minimize sea travel.

The J.v.G. analysis, however, revealed a more optimal path. By sourcing the bulky solar glass from a supplier in Germany, the project immediately eliminated significant transport costs and all intercontinental customs complexities for its heaviest raw material. For the remaining components from Asia, routing them through Rotterdam and using a dedicated rail service to a Swiss hub proved 15% more cost-effective and three days faster on average than the southern sea route, thanks to highly efficient rail infrastructure and a streamlined customs process managed by a long-standing logistics partner.

This example illustrates that the most obvious route is not always the most efficient. A successful setup requires a holistic view, as detailed in the guide, How to Start a Solar Module Factory: A Step-by-Step Plan.

Frequently Asked Questions (FAQ)

Why would an entrepreneur choose a landlocked location like Liechtenstein for manufacturing?

Liechtenstein offers compelling non-logistical advantages, including a stable political and economic environment, a highly skilled workforce, liberal economic policies, and a central location for distributing finished products throughout Europe. With proper planning, these benefits can far outweigh the logistical complexities.

Does the customs union with Switzerland simplify or complicate logistics?

For a well-prepared business, it simplifies logistics. The union creates a larger, more integrated economic area and provides access to Switzerland’s world-class infrastructure and expertise. The key is understanding the specific documentation required, as it differs from standard EU procedures.

What are the primary raw materials a solar module factory needs to source?

The main materials include solar cells, solar glass, aluminum frames, EVA (ethylene vinyl acetate) encapsulant, and backsheets. Each has different sourcing origins, handling needs, and logistical profiles.

How long does customs clearance typically take for goods arriving from Asia?

With a professional customs broker and all documentation prepared correctly in advance, clearance at the Swiss border can often be completed within 24-48 hours of the shipment’s arrival. Errors in paperwork, however, can lead to delays of a week or more.

From Logistical Hurdles to Strategic Advantage

A landlocked location like Liechtenstein presents a unique set of logistical challenges, but they are far from insurmountable. By thoroughly analyzing transport routes, strategically selecting suppliers, and engaging expert logistics partners, an entrepreneur can design a supply chain that is not just functional but truly resilient and efficient.

Ultimately, the success of a manufacturing plant in any location hinges on meticulous planning. The complexities of a landlocked supply chain simply underscore the importance of seeking expert guidance early, transforming potential obstacles into a well-managed and reliable operational foundation.