Rebuilding a city like Benghazi is about more than bricks and mortar; it’s about restoring the essential services that allow a community to thrive. Yet this progress faces a fundamental obstacle: an unreliable and overburdened power grid.

With daily power cuts lasting 10 to 14 hours, critical facilities like hospitals, water treatment plants, and administrative buildings are forced to rely on expensive, high-maintenance diesel generators. The result is a cycle of dependency and operational instability that hinders long-term recovery.

A strategic alternative exists that could transform this energy deficit into a catalyst for industrial growth and energy independence. This proposal outlines a clear, actionable plan to establish a medium-scale solar module factory in Benghazi. More than just supplying a product, such a facility would provide the foundational tool for building a resilient, self-sufficient future for the city’s core infrastructure.

The Strategic Imperative: Energy Sovereignty for Benghazi’s Reconstruction

For a city undergoing large-scale rebuilding, the source of its energy is as important as the materials used in construction. While importing solar panels is a viable short-term solution, establishing local manufacturing offers profound, long-term strategic advantages:

-

Supply Chain Control: A local factory eliminates dependency on complex international logistics and fluctuating import costs, ensuring a steady supply of modules for critical projects.

-

Economic Development: The facility would create skilled jobs for engineers, technicians, and operators, contributing directly to the local economy and fostering a new industrial sector.

-

Technology Transfer: Operating a modern manufacturing plant brings valuable technical knowledge and skills into the region, creating a foundation for future technological growth.

-

Customized Solutions: A local facility can produce modules specifically engineered for Benghazi’s challenging climate, ensuring greater durability and performance than generic imported alternatives.

This initiative directly addresses the energy vulnerability exposed by damage to key infrastructure like the Benghazi North power plant. By producing the means of power generation locally, the city can systematically decentralize its energy supply, making critical services resilient to grid failures.

Project Blueprint: A 50 MW Turnkey Solar Factory

The proposed project is a 50 MW-per-annum solar module assembly plant. This capacity is large enough to make a significant impact on public infrastructure needs yet manageable for a new market entrant in terms of investment and operational complexity.

Key Project Specifications

-

Annual Capacity: 50 Megawatts (MW). This output is sufficient to equip numerous hospitals, schools, and water purification facilities with independent power systems each year.

-

Facility Footprint: The production line requires approximately 3,000–4,000 square meters of industrial space, which can be accommodated in a new or retrofitted building.

-

Required Workforce: The factory would employ a team of 40–50 personnel, including managers, engineers, skilled technicians, and line operators.

-

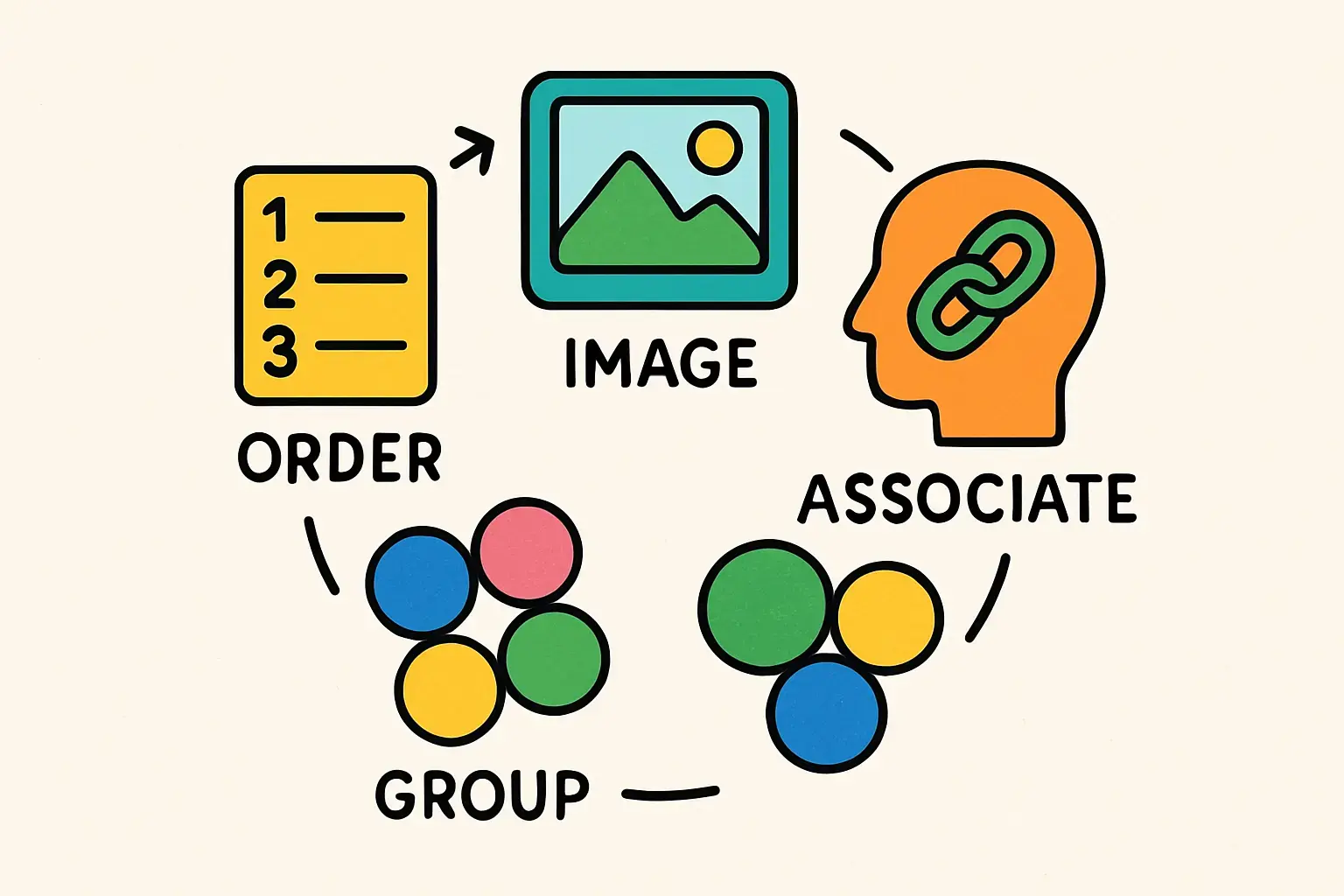

Core Technology: The plant would be configured to assemble high-efficiency monocrystalline PERC (Passivated Emitter and Rear Cell) modules, a globally recognized standard for performance and reliability. A detailed overview of the Solar Module Manufacturing Process illustrates how these components come together to create a finished product.

Investment Outline

Establishing a solar factory is a significant undertaking, but a structured approach makes the financial requirements predictable. The total investment for setting up a solar panel factory of this scale falls within a defined range, covering essential capital expenditures. Key cost centers include:

-

Production Machinery: The core of the investment, including the laminator, stringer machine, and testing equipment.

-

Facility Preparation: Costs associated with preparing the building, including cleanroom areas, electrical systems, and compressed air supply.

-

Initial Raw Materials: A starting inventory of solar cells, glass, EVA encapsulant, backsheets, and aluminum frames.

-

Training & Commissioning: Fees for expert engineers to install the equipment and train the local team.

Drawing on experience from J.v.G. turnkey projects, a detailed business plan can be developed to outline these costs and project long-term profitability based on production output and market demand.

A Phased Deployment Plan: From Concept to Production in 10 Months

For a project of this strategic importance, speed and efficiency are critical. A turnkey solar manufacturing line approach minimizes delays and risks by consolidating project management, machine procurement, and installation under a single experienced partner. This integrated method ensures a predictable and accelerated timeline, from the initial decision to the first certified module coming off the line.

This structured 10-month deployment ensures that every phase, from site preparation to staff training, follows proven industry standards, significantly de-risking the venture for investors and stakeholders.

Engineering for the Environment: The DESERT+ Module Advantage

Benghazi’s climate presents challenges that standard solar modules are not designed to handle. The combination of high temperatures, intense solar irradiation, and abrasive sand and dust requires a specially engineered solution.

The proposed factory would be equipped to produce DESERT+ modules, a technology developed by J.v.G. Technology GmbH specifically for such environments. These modules incorporate several key features:

-

High-Temperature Performance: Specialized cell and material combinations maintain high efficiency even during the hottest parts of the day.

-

Durable, Anti-Soiling Glass: A unique coating reduces the adhesion of dust and sand, simplifying cleaning, maintaining performance, and protecting the glass from abrasion.

-

Robust Frame Design: The reinforced frame is built to withstand high wind loads and the mechanical stress associated with sandstorms.

By producing these specialized modules locally, Benghazi can ensure its solar installations deliver maximum output and have a service life of 25+ years, securing the long-term energy supply for its most critical infrastructure.

Frequently Asked Questions (FAQ)

What level of technical expertise is required from the project owner?

The project owner’s role is primarily that of a business leader and entrepreneur. The turnkey model is designed for investors without a background in photovoltaics. A technical partner like J.v.G. provides the necessary engineering, process knowledge, and operational training to ensure the factory runs successfully.

How are staff trained to operate the machinery?

A comprehensive training program is a core component of the turnkey package. The program involves on-site instruction by experienced engineers during the installation and commissioning phase. Local staff are trained on machine operation, quality control protocols, and routine maintenance until they are fully competent to manage the production line independently.

Where would the raw materials for the modules be sourced from?

Raw materials like solar cells, glass, and aluminum frames are sourced from established international suppliers. Establishing these supply chains is a key part of the turnkey service, ensuring access to high-quality, cost-effective materials from day one.

Is a 50 MW factory scalable for future growth?

Yes. The initial facility layout can be planned with future expansion in mind. As local or regional demand grows, a second production line can be added to the existing building, doubling capacity with significantly lower incremental investment in infrastructure.

For entrepreneurs and institutions considering this strategic investment, the path forward involves a detailed feasibility study and financial modeling. A well-structured project, grounded in proven technology and experienced partnership, represents a powerful opportunity to not only rebuild Benghazi’s infrastructure but also to establish the city as a regional leader in renewable energy manufacturing.