A solar panel factory on a remote Maldivian atoll presents a powerful image: clean energy technology produced in a paradise threatened by climate change. But this idyllic picture conceals a critical business challenge.

What happens to the inevitable manufacturing waste—the broken cells, trimmed materials, and off-cuts—in a place with no landfill space? And what is the long-term plan for the solar modules themselves once they reach the end of their 25-year service life?

For any entrepreneur entering the solar manufacturing industry, particularly in an environmentally sensitive location, these questions are not peripheral. They are central to a project’s viability, its profitability, and its social license to operate. Addressing waste management from the outset is the hallmark of a well-planned, sustainable, and ultimately more successful enterprise.

The Hidden Challenge of Solar: Production Waste and End-of-Life Modules

While solar energy is celebrated for its clean power generation, the manufacturing process creates waste streams that require careful management. These fall broadly into two categories:

-

Manufacturing Scrap: During production, even in the most efficient facilities, up to 5% of materials can become scrap. This includes cracked silicon wafers, trimmed encapsulant (EVA) and backsheet materials, off-cuts from aluminum frames, and rejected modules that fail quality control.

-

End-of-Life (EoL) Modules: A standard solar module has a lifespan of 25 to 30 years. This means every panel produced today becomes a future waste management obligation. For a new manufacturer, establishing a plan for this eventuality demonstrates foresight and responsibility.

Ignoring these factors can lead to significant operational costs, regulatory penalties, and reputational damage, especially in regions where the environment is a core economic asset.

Case Study: The Maldives – High Stakes for Sustainability

The Republic of Maldives, a nation of over 1,000 coral islands, is a compelling example of why sustainable manufacturing practices are essential. The country’s economy relies heavily on tourism, which depends on its pristine natural environment. As a low-lying archipelago, it is also acutely vulnerable to the effects of climate change, making the transition to renewable energy a national priority.

The Maldivian government has set an ambitious goal to achieve net-zero emissions by 2030 and implemented stringent environmental regulations to protect its delicate marine ecosystems. For a solar manufacturer operating here, a conventional ‘take, make, dispose’ model is simply unfeasible. Landfill is not an option, and the logistical costs of shipping waste abroad are prohibitive.

This context forces a smarter, more circular approach—one that transforms waste from a liability into a potential asset. While acute in the Maldives, this challenge offers a valuable blueprint for projects in other sensitive regions, from protected coastal zones in the Middle East to agricultural heartlands in Africa.

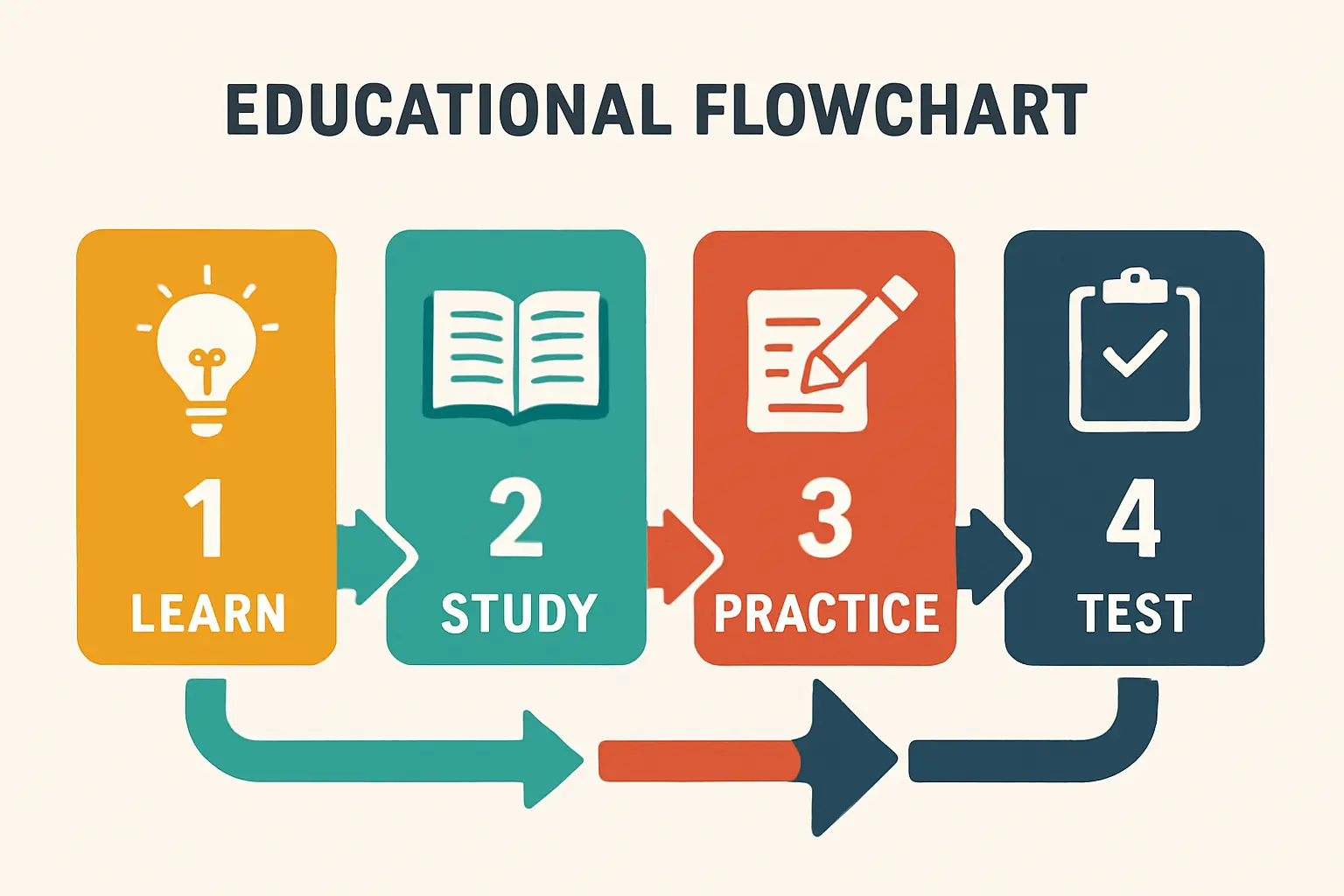

A Framework for a Circular Economy in Solar Manufacturing

A circular economy moves away from a linear model of production and disposal, focusing instead on designing out waste, keeping materials in use, and regenerating natural systems. For a solar factory, this framework can be applied to both manufacturing scrap and EoL modules.

Managing Manufacturing Scrap

The most effective way to manage waste is to minimize its creation in the first place.

Reduction through Process Excellence: Investing in a high-quality, well-configured turnkey solar manufacturing line is the first step. Precision automation, robust handling systems, and integrated inspection points reduce cell breakage and material misuse. A superior solar panel quality control protocol ensures defects are caught early, preventing the waste of valuable downstream materials. Experience from J.v.G. turnkey projects, for instance, shows that meticulous line calibration can significantly lower scrap rates and directly improve the bottom line.

Segregation and Recycling: For the scrap that is inevitably produced, a disciplined segregation process is key.

-

Metals: Aluminum from frame off-cuts and copper from tabbing ribbon are highly recyclable. Aluminum frames can be 100% recycled with relatively low energy input, representing a clear value stream.

-

Silicon: Broken solar cells, while not suitable for high-efficiency modules, may be sold to manufacturers of lower-power products or recycled to recover the high-purity silicon.

-

Polymers: Waste from EVA and backsheets is more challenging to recycle. However, options like thermal or chemical processing are emerging, and segregated polymer waste may find a secondary market.

Planning for End-of-Life (EoL) Modules

A credible long-term business plan must include a strategy for modules once they reach the end of their service life. A typical solar panel is composed of glass (~75%), polymers (10%), aluminum (8%), silicon (5%), and small amounts of other metals like silver and copper (2%). The primary challenge is separating these materials efficiently.

The process typically involves:

-

Frame Removal: The aluminum frame is detached for straightforward recycling.

-

Delamination: The bond between the glass, encapsulant, and backsheet is broken. This is the most complex step and can be done using thermal, mechanical, or chemical methods.

-

Material Separation: The separated components—glass, silicon cells, and metallic conductors—are sorted.

Recovered materials like high-purity silicon and silver have significant economic value, which helps to offset recycling costs. Establishing partnerships with regional or international recycling specialists early on can provide a clear and cost-effective pathway for EoL management.

Building a Social License to Operate

In many emerging markets, a company’s commitment to environmental stewardship is a critical factor in securing permits, financing, and community support. By designing a factory with a robust waste management and circular economy plan, a business shows it is a responsible partner committed to the long-term well-being of the region. This builds invaluable trust with government agencies, local communities, and international investors, de-risking the entire venture.

Frequently Asked Questions (FAQ)

Is it expensive to manage solar manufacturing waste?

While setting up segregation systems and recycling services requires an initial investment, these costs should be weighed against the high long-term expenses of unmanaged waste, such as disposal fees, regulatory fines, and the potential loss of operational permits. A well-designed waste management system is an investment in operational resilience and risk mitigation.

Can a small-scale factory handle recycling on-site?

Full-scale EoL module recycling requires specialized industrial facilities and is typically not feasible for a single manufacturing plant to operate. The practical approach is to focus on efficient on-site segregation of manufacturing scrap and to establish formal agreements with certified third-party recycling companies for both production waste and future EoL modules.

What are the first steps to creating a waste management plan?

The process begins with a detailed material audit to understand the types and volumes of waste your specific production line will generate. Next, thoroughly research and comply with all local, national, and international environmental regulations. Finally, design internal processes for waste segregation and identify external partners for recycling and disposal.

How does the choice of raw materials for solar panel production affect recyclability?

The selection of raw materials for solar panel production can have a significant impact. For example, some modern backsheets and encapsulants are being designed for easier separation and recycling. Sourcing materials from suppliers who consider the end-of-life phase can simplify future waste management challenges and align the business with circular economy principles.

Conclusion: From Linear Production to a Circular Legacy

In the past, manufacturing success was a straight line: raw materials in, finished products out. Today, especially in the clean energy sector and ecologically sensitive regions, success is circular.

Thinking about waste management and end-of-life planning from day one is not just an environmental obligation—it is a sophisticated business strategy. It reduces operational risk, can create new value streams, and builds the corporate reputation necessary to thrive in the global market. For the entrepreneur looking to build a lasting legacy in the solar industry, designing a factory that is as clean in its operations as the energy its products will generate is the ultimate measure of success.