Mongolia boasts one of the highest solar irradiation levels globally, presenting a significant opportunity for renewable energy generation. As entrepreneurs and investors look to diversify the nation’s mining-heavy economy, solar module manufacturing has emerged as a logical venture. A critical question, however, is whether the local labor market has the necessary skills to support a high-tech manufacturing facility.

While hiring for a new industry can seem daunting, a closer look reveals a landscape of both distinct challenges and considerable potential. Success lies not in finding a perfectly pre-trained workforce, but in understanding the existing talent pool and implementing a strategic approach to skill development.

Understanding the Workforce in a Modern Solar Factory

A semi-automated solar module production line requires a well-coordinated team with a diverse range of technical skills. A typical starter facility with an annual capacity of around 50 MW typically requires an operational team of 40 to 50 employees working across shifts. These roles are not uniform, falling into several distinct categories with their own specific requirements.

Based on experience from J.v.G. turnkey projects, the primary challenge for new investors is often not the quantity of available labor, but the quality and specificity of technical training. Understanding these distinct roles is the first step in evaluating the local market.

The Mongolian Labor Landscape: A Paradox of Potential

The Mongolian labor market presents a unique paradox for industrial investors. While demographic and educational data are highly promising, specific industrial skills are scarce due to the long-standing dominance of the mining sector.

A Young and Educated Population

According to UNICEF data, young people aged 15-34 make up a third of Mongolia’s population, creating a large, dynamic pool of potential employees. The International Labour Organization (ILO) also reports high educational attainment, including a 99% literacy rate and strong enrollment in tertiary education. This educational foundation suggests a workforce capable of learning complex processes.

The Challenge of Skills Mismatch

Despite these high education levels, both UNICEF and the ILO highlight a significant ‘skills mismatch.’ The educational system and vocational training have historically been tailored to the mining and pastoral industries, leading to a high rate of youth unemployment (15.5%) and underemployment. Nearly 29% of young people are classified as NEET (Not in Education, Employment, or Training).

Many university graduates and technicians have strong theoretical knowledge but lack the practical, hands-on experience required in a sophisticated manufacturing environment. This is a common challenge for entrepreneurs learning how to start a solar factory in emerging markets.

Identifying Key Roles and Potential Skill Gaps

To build an effective team, an investor must break down the factory’s needs and map them against available talent. The roles in a solar module factory can be structured into a clear hierarchy.

Line Operators

Operators perform manual and semi-automated tasks like loading materials and transferring components between stations.

Availability in Mongolia: High. The large youth demographic creates an ample pool of candidates who can be trained for these roles relatively quickly.

Quality Control (QC) Inspectors

QC inspectors are responsible for visual and machine-assisted inspections at various stages of production to ensure compliance with quality standards.

Availability in Mongolia: Moderate. While the role requires strong attention to detail, the core skills are trainable. Candidates with any prior experience in quality assurance can adapt quickly.

Maintenance Technicians (Mechanical & Electrical)

This is the most critical and often hardest-to-fill category. These technicians handle the setup, preventative maintenance, and troubleshooting of sophisticated production machinery, including systems with Programmable Logic Controllers (PLC).

Availability in Mongolia: Low. A decades-long focus on heavy mining equipment has created a shortage of technicians experienced with the precise automation and robotics used in modern manufacturing. This is the primary skill gap an investor must address.

Process and Production Engineers

Engineers oversee the entire production process, optimizing efficiency, managing output, and solving complex technical problems.

Availability in Mongolia: Moderate. The country produces many engineering graduates, but they often lack specific experience in photovoltaic manufacturing or lean production methodologies. While they have strong theoretical foundations, they require practical, on-the-job training.

A Strategic Approach to Building a Skilled Local Workforce

Recognizing the skills gap is not a barrier but the starting point for a targeted workforce development strategy. A proactive approach, often integrated into the setup of a turnkey solar module production line, can bridge this gap effectively.

1. Structured, On-Site Training Programs

The most effective method is a comprehensive training program delivered by equipment suppliers during installation and commissioning. This approach ensures the local team learns on the exact machinery they will operate, a crucial step in transforming a new crew into a proficient production team.

2. The ‘Train the Trainer’ Model

A practical, cost-effective strategy is to send a small core team of key engineers and lead technicians abroad for intensive training at the machine manufacturer’s facility. Upon their return, these highly skilled individuals become internal trainers, mentoring the rest of the local workforce and building sustainable, in-house training capacity.

3. Leveraging Adjacent Industry Skills

While direct experience may be lacking, technicians from the mining or food processing industries often have transferable skills in mechanical and electrical systems. A focused training program can help them adapt this knowledge to the specific requirements of solar manufacturing automation, reducing the learning curve.

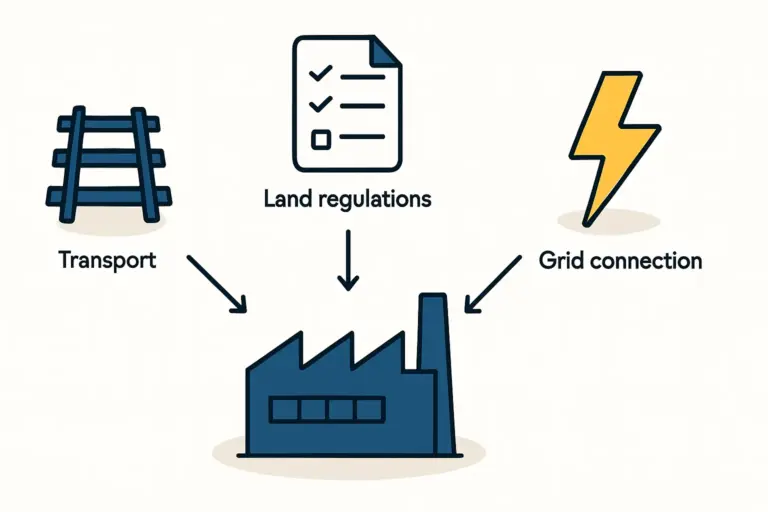

4. Aligning with National Diversification Goals

The Mongolian government and international partners, through initiatives like the USAID Business Plus Initiative, are actively supporting economic diversification. A new solar manufacturing venture aligns perfectly with these goals, creating potential opportunities for collaboration on vocational training programs and workforce development grants.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale solar factory?

A 20–50 MW semi-automated production line typically requires 30 to 50 employees, including operators, technicians, engineers, and administrative staff, often spread across two shifts. This number is a key factor in calculating the overall investment for a solar panel factory.

What is the most difficult role to fill from the local Mongolian market?

Based on analysis, the Maintenance Technician role, specifically for those with experience in PLC systems and fine automation, presents the greatest hiring challenge. A dedicated training plan for this role is essential.

Is a university degree required for all positions?

No. Line operator and many junior technician roles are well-suited for graduates of vocational schools or individuals with strong mechanical aptitude who receive structured on-the-job training. Engineering and senior management roles, however, typically require a university degree in a relevant field.

How long does it take to fully train a new team?

Initial operational training during the commissioning of the production line typically lasts four to six weeks. However, achieving peak efficiency and developing a deeply skilled maintenance team is an ongoing process that takes 6 to 12 months of continuous operation and development.

From Potential to Production: A Realistic Outlook

The Mongolian labor market, while not immediately plug-and-play for high-tech manufacturing, holds immense potential. Its young, educated, and motivated population is a significant asset. The primary hurdle—a skills mismatch in specialized technical areas—is a solvable problem.

Success depends not on finding a perfect workforce, but on having a clear, realistic plan to build one. With a strategy centered on targeted recruitment, intensive training, and knowledge transfer, an investor can develop a highly capable local team and turn Mongolia’s solar potential into a productive reality.