An established energy company with decades of experience in large-scale project management and capital deployment stands at a strategic crossroads. With the global energy landscape undergoing a fundamental shift, long-term value lies in diversifying assets beyond traditional fossil fuels. For such an organization, the question is not if it should enter the renewables sector, but how to do so in a way that leverages existing strengths and secures a competitive advantage.

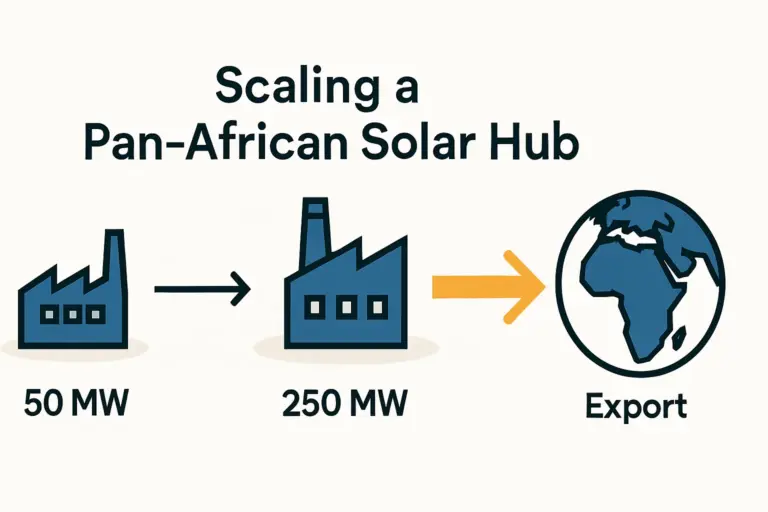

This blueprint outlines a strategic pathway for an energy major to channel capital into a high-value, future-proof venture: establishing a 250 MW Heterojunction (HJT) solar module manufacturing facility. Using the Jorf Lasfar Industrial Park in Morocco as a prime example, this plan is not merely about entering a new market; it is about applying decades of industrial expertise to a high-growth technology vertical.

The Strategic Imperative: Why Solar Manufacturing?

For a company accustomed to managing complex supply chains and large-scale infrastructure, direct manufacturing offers a more strategic entry point than simply investing in solar farms. It provides greater control over technology, quality, and supply, positioning the company as a key enabler of the energy transition in its region.

Its core competencies are highly transferable:

- Project Management: The discipline required to build a refinery or a power plant is directly applicable to constructing a state-of-the-art manufacturing facility.

- Capital Allocation: Decades of experience managing multi-million-dollar budgets ensures financial discipline and a focus on long-term ROI.

- Supply Chain & Logistics: Existing networks can be adapted to source raw materials and distribute finished products efficiently.

The primary challenge lies not in operational capability but in technical unfamiliarity. This is where choosing the right technology and partners becomes critical.

Choosing the Right Technology: The Case for Heterojunction (HJT)

When entering a new market, a “me-too” strategy is insufficient. Leadership requires adopting a technology that offers a distinct and sustainable advantage. Heterojunction (HJT) solar cells represent such a technological leap.

In simple terms, an HJT cell is a “sandwich” of different silicon layers. At its core is a high-purity N-type monocrystalline silicon wafer, coated with ultra-thin layers of amorphous silicon. This unique structure dramatically reduces energy losses at the cell surface, leading to superior performance.

The business case for HJT is compelling and supported by extensive industry data:

- Superior Efficiency: HJT modules consistently achieve higher conversion efficiencies than conventional technologies like PERC. The International Technology Roadmap for Photovoltaics (ITRPV) places HJT technology on a clear trajectory to exceed 26% cell efficiency in mass production, which directly translates to more power per square meter.

- Excellent High-Temperature Performance: HJT cells have a superior temperature coefficient, meaning they lose less power in hot climates. This is a crucial advantage for projects in the Middle East, Africa, and other sun-rich regions.

- Higher Bifaciality: HJT cells are naturally bifacial, capable of capturing reflected light from their rear side. This can increase energy yield by 10-25% in utility-scale installations, significantly lowering the Levelized Cost of Energy (LCOE).

- Growing Market Share: While PERC is the current market leader, ITRPV projections point to a rapid rise for N-type technologies like HJT, which are expected to capture over 50% of the market within the next decade. Investing in HJT is an investment in the future standard.

By choosing HJT, an energy major can avoid competing in the crowded, commoditized market of conventional modules and instead position itself as a premium technology provider.

The Jorf Lasfar Advantage: A Case Study in Site Selection

Choosing a location is as critical as selecting the right technology. An industrial hub like Jorf Lasfar in Morocco offers a powerful combination of advantages for a solar manufacturing facility.

- Infrastructure: Access to a deep-water port, reliable utilities, and established transport links streamlines logistics for importing raw materials and exporting finished modules.

- Government Support: Designated industrial zones often provide investment incentives, simplified administrative processes, and a favorable tax environment.

- Market Access: Proximity to growing energy markets in Africa and Europe reduces shipping costs and lead times, creating a significant competitive edge.

The decision of where to build requires a detailed analysis of the investment requirements for a solar factory, factoring in land, construction, utilities, and logistics.

The Blueprint for a 250 MW HJT Facility

An annual capacity of 250 MW is a strategic starting point. This scale is large enough to achieve economies of scale and supply utility-scale projects, yet remains manageable from an execution standpoint. Based on experience from J.v.G. Technology turnkey projects, such a facility would typically require a building of 10,000–15,000 square meters and a workforce of approximately 150–200 employees, including operators, technicians, and administrative staff.

Implementation can be broken down into clear phases.

Phase 1: Detailed Feasibility and Planning

This initial phase involves comprehensive financial modeling, developing a raw material sourcing strategy, and defining the precise bill of materials (BOM) for the HJT modules. This phase culminates in a solidified, detailed business plan.

Phase 2: Technology and Equipment Selection

For a high-tech HJT line, partnering with experienced European equipment suppliers is crucial. A highly automated production line minimizes human error, ensures consistent quality, and maximizes throughput. Key equipment includes systems for cell texturing and cleaning, plasma-enhanced chemical vapor deposition (PECVD) for the amorphous silicon layers, and advanced lamination and testing.

Phase 3: Facility Construction and Human Capital

While the specialized equipment is being manufactured, the factory building can be constructed or retrofitted. Concurrently, a core team of engineers and managers should be recruited and trained at the equipment supplier’s facilities, ensuring they are prepared to oversee installation and commissioning. This process is detailed in guides on how to start a solar module production line.

Phase 4: Execution, Commissioning, and Ramp-Up

This phase involves installing the equipment, connecting utilities, and running initial test batches. The ramp-up to full 250 MW capacity is a gradual process over several months, focusing on process optimization and quality control to achieve target yields and efficiency ratings.

Mitigating Risk: From Technology to Market

Any major capital investment carries risk, but a structured approach can effectively mitigate the key challenges.

- Technology Risk: While HJT is an advanced technology, it is not experimental. It has been in mass production for years, and its manufacturing processes are well-established. Partnering with a proven turnkey provider who guarantees the line’s performance is the most effective way to de-risk technology adoption.

- Market Risk: The primary off-takers for high-efficiency modules will be utility-scale solar projects—a segment already familiar to energy majors. By producing a premium, high-performance product, the facility can target large projects where a lower LCOE is the primary decision factor. The module itself becomes a key selling point.

- Operational Risk: Automation is key to minimizing operational risk. It reduces dependency on manual labor, improves product consistency, and lowers defect rates. Comprehensive training and clear standard operating procedures (SOPs) will ensure the facility runs at peak efficiency.

The end goal is a product that embodies quality and performance, building a strong brand reputation in the renewable energy sector.

Frequently Asked Questions (FAQ)

What exactly is Heterojunction (HJT) technology?

HJT is an advanced solar cell architecture that combines two different technologies: a crystalline silicon wafer and ultra-thin layers of amorphous “thin-film” silicon. This hybrid structure is highly effective at minimizing energy loss, resulting in higher efficiency and better performance than conventional cells.

Why is a 250 MW capacity recommended for a new entrant?

A 250 MW facility strikes a balance between manageable investment and commercial viability. It is large enough to secure favorable pricing on raw materials and to be a credible supplier for large, multi-megawatt solar power plants.

What is the typical investment range for such a facility?

The capital expenditure for a 250 MW HJT line depends heavily on the level of automation and the choice of equipment suppliers. A complete turnkey setup, including all processing and testing equipment, typically falls in the range of $25 million to $40 million USD.

How long does it take for a factory like this to become operational?

With a well-defined plan and an experienced partner, the timeline from project kick-off to the first module being produced is typically 12 to 18 months. This includes factory design, equipment manufacturing and shipping, installation, and commissioning.

Does our company need deep in-house solar expertise to start?

Not necessarily. The key is to leverage existing expertise in project management and finance. Technical solar knowledge can be acquired by partnering with an experienced engineering and consultancy firm that provides turnkey solutions. To bridge this knowledge gap for business professionals, pvknowhow.com provides structured e-courses and resources.

The Path Forward

For an established energy major, expanding into solar module manufacturing is a logical and strategic evolution. It leverages core strengths while positioning the company at the forefront of the energy transition. By selecting a future-proof technology like HJT, choosing a strategic location, and partnering with experienced technology providers, an energy leader can build a new, profitable, and sustainable business division.

The next step is to develop a deeper understanding of the end-to-end process. Exploring the specifics of what is a solar module turnkey production line provides a comprehensive overview of how a concept is transformed into a fully operational manufacturing facility.