Setting up a solar module factory is a formidable undertaking anywhere in the world. When the location is a remote island nation like Nauru, the logistical complexities multiply, demanding planning that goes far beyond standard supply chain management.

The ambition to harness abundant sunlight for local energy production is commendable, but its success hinges on navigating a unique set of importation hurdles. An entrepreneur might secure the finest equipment and the necessary capital, only to find the entire project stalled by a single overlooked detail: the physical constraints of getting the machinery to the island.

This article details the logistical realities of shipping heavy industrial equipment to Nauru. It outlines the key challenges, from maritime transport limitations to on-island infrastructure, offering a clear-eyed perspective for business professionals and project planners considering such a venture.

The Unique Geographical Context of Nauru

Understanding the logistics of shipping to Nauru begins with appreciating its geography. Nauru is one of the world’s smallest and most isolated independent states, a single island of just 21 square kilometers in the Central Pacific. It lies approximately 4,000 kilometers northeast of Australia, its nearest major economic partner. This isolation is not merely a fact on a map; it is the defining factor for its entire supply chain.

Unlike continental locations or islands on major shipping superhighways, Nauru is not a routine stop for international freight lines. All goods, from consumer products to industrial machinery, must travel a long and often indirect sea route, typically transshipping through larger regional hubs like Brisbane, Australia, or Suva, Fiji. This adds time, cost, and complexity before the cargo even approaches Nauruan waters.

Navigating Nauru’s Maritime Gateway: The Aiwo Harbour Bottleneck

The most critical element in Nauru’s importation logistics is the Aiwo Harbour. The island’s steep offshore coral reefs have prevented the construction of a deep-water port capable of berthing large container ships. Instead, vessels must moor offshore, several hundred meters from the island itself.

This arrangement requires a specialized cargo transfer process known as lighterage.

The Cantilever Crane and Lighterage System

At the port, two large cantilever cranes extend out over the water. These cranes are the backbone of the unloading process. They lift containers and heavy items directly from the moored vessel and place them onto smaller, flat-topped barges called lighters. These lighters are then towed into the small boat harbor for unloading.

This system poses several distinct challenges for importing heavy machinery:

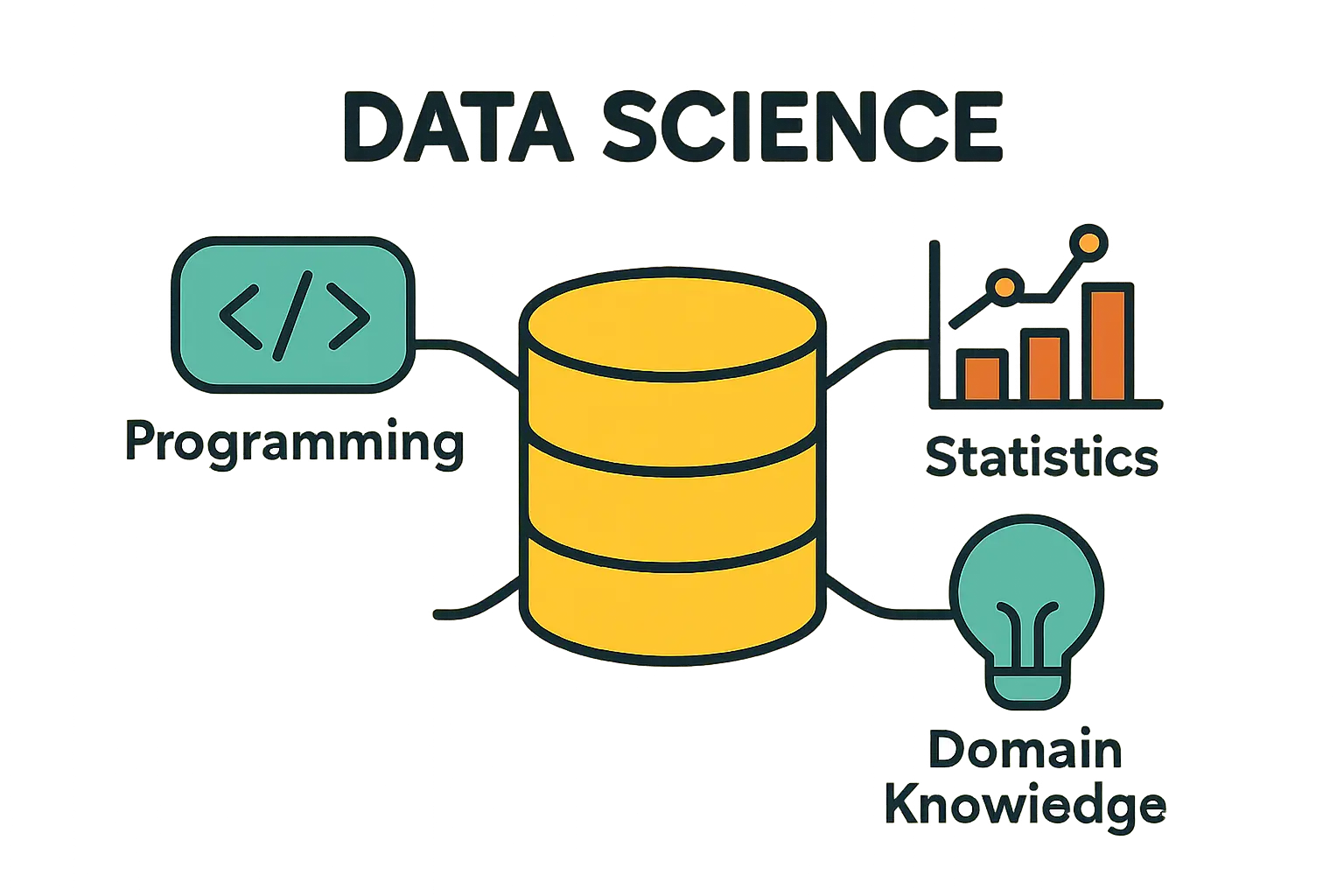

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

-

Weight Limitation: The cantilever cranes have a maximum safe working load, typically in the range of 30 to 40 tonnes. Any single piece of equipment or crated item exceeding this limit cannot be offloaded. This is a crucial constraint for heavy machinery like solar module laminators or glass washing units.

-

Weather Dependency: The entire lighterage operation is highly susceptible to sea conditions. Swells and rough seas make it unsafe for the ship to moor and for the cranes to transfer cargo to the bobbing barges. It is not uncommon for operations to be suspended for days, or even weeks, waiting for a calm weather window. This introduces significant and unpredictable delays.

-

Operational Bottleneck: The process of transferring cargo piece by piece via barge is inherently slow compared to a standard container terminal, creating a bottleneck that limits the volume of goods that can be processed in a given day.

Based on J.v.G. turnkey projects in other locations with logistical challenges, verifying the exact weight and dimensions of every crate long before shipping is essential. A miscalculation can result in cargo being returned to its port of origin at a substantial cost.

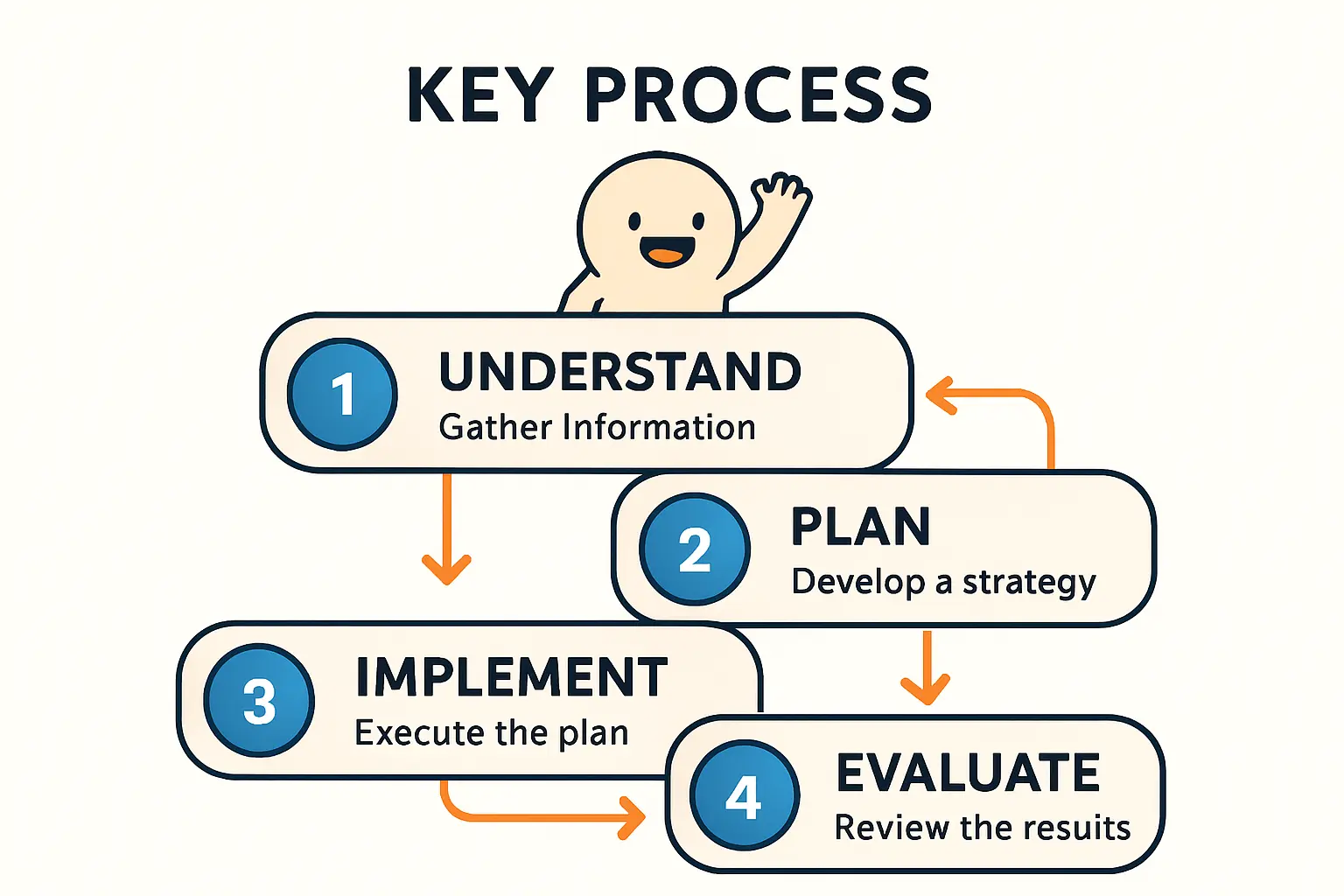

The Critical Path: From Manufacturer to Factory Floor

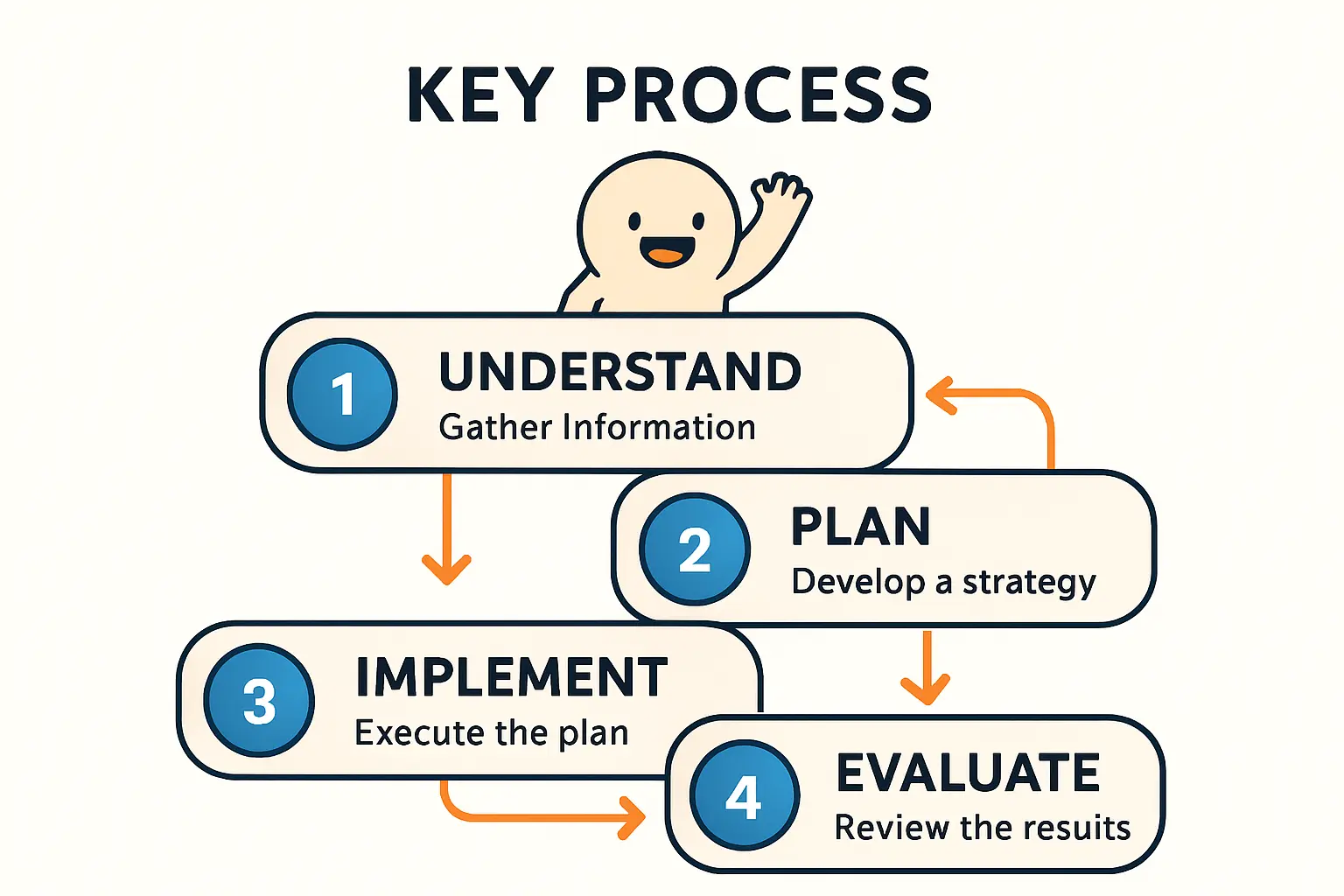

The journey of solar production equipment to a Nauruan factory site is a multi-stage process requiring meticulous coordination. Each stage introduces potential delays and requires precise documentation.

Step-by-Step Logistical Flow

-

Ex-Works & Crating: The process begins at the machinery manufacturer’s facility. All components of the solar panel production equipment must be professionally crated for a sea voyage, with special attention to weight distribution and moisture protection. Each crate’s final weight and dimensions must be confirmed to comply with Nauru’s crane limitations.

-

Ocean Freight to Transshipment Hub: The cargo is shipped via a standard container vessel to a major regional port, such as Brisbane. Here, it is offloaded and awaits the less frequent feeder vessel service to Nauru.

-

Feeder Vessel to Nauru: The cargo is loaded onto a smaller ship equipped to handle the offshore mooring and lighterage system at Aiwo. The schedule for these vessels can be infrequent, sometimes only once or twice a month.

-

Offshore Unloading (Lighterage): Upon arrival, the vessel moors offshore, and the crane-and-barge transfer begins, subject to weather conditions.

-

Customs & Quarantine Clearance: Once ashore, the cargo must clear Nauruan customs and biosecurity inspections. As with any import process, accurate and complete documentation (bill of lading, commercial invoice, packing list) is paramount to avoid delays.

-

Inland Transport: The final leg of the journey is moving the equipment from the port to the designated factory site. The island’s road network is limited, and the availability of heavy-duty cranes and flatbed trucks for transport must be pre-arranged. To ensure a smooth transition from port to foundation, the logistics for a full turnkey solar manufacturing line must be planned in concert with the factory building requirements.

Planning for Reality: Timelines and Cost Factors

Standard shipping time calculators are simply not applicable to Nauru. A project planner must build in significant buffers.

-

Timeline Estimation: While a sea journey from Asia to Australia might take 3-4 weeks, the total journey to Nauru can easily stretch to 8-12 weeks or more. This accounts for waiting times at the transshipment port and potential weather delays at Aiwo Harbour.

-

Cost Implications: Freight costs are substantially higher due to the multiple handling stages and specialized shipping services. Businesses must also budget for:

-

Higher Insurance Premiums: Insurers recognize the increased risk associated with the offshore transfer process.

-

Potential Demurrage Fees: If the ship is forced to wait an extended period for calm seas, the shipping line may charge demurrage fees for the delay.

-

Contingency Funds: A budget for unforeseen logistical costs is not just advisable; it is a necessity.

Frequently Asked Questions (FAQ)

What is the single biggest logistical challenge for Nauru?

The reliance on the offshore lighterage system is the greatest challenge. It imposes strict weight limits, is entirely dependent on calm weather, and creates a significant bottleneck that affects timelines and costs for all imports.

Can standard 40-foot containers be imported into Nauru?

Yes, standard 20-foot and 40-foot containers can be imported. However, their total weight (container plus cargo) must not exceed the maximum lift capacity of the cantilever cranes at Aiwo Harbour.

How can one mitigate the risk of weather-related delays?

The best mitigation strategy is proactive planning. This involves building several weeks of buffer time into the project schedule. Maintaining constant communication with an experienced freight forwarder who understands the region is also critical for timely updates on port conditions.

Is it necessary to have a local logistics partner in Nauru?

While on-island logistics providers are limited, working with an international freight forwarder who has established relationships and operational experience with Nauru is essential. They can coordinate with the Nauru Port Authority and local handlers to manage the complex clearance and inland transport processes.

What happens if a piece of equipment is too heavy for the cranes?

If a single crate exceeds the crane’s weight limit, it cannot be offloaded. The item would either have to remain on the vessel and be returned to the port of origin, or alternative, highly complex, and expensive offloading methods would need to be arranged, if at all possible. This underscores the importance of verifying weights before shipment.

Establishing a solar module production facility in Nauru is a venture with great potential, but one that is fundamentally a logistics project first and a manufacturing project second. Success requires a deep understanding of the island’s unique constraints and a planning process that is both conservative and meticulous. Engaging with logistics experts and engineering partners who have experience in remote locations is a critical step toward turning this ambitious goal into a successful reality.