An investor evaluating Nauru for a new enterprise might first see its strategic location and growing demand for renewable energy. The initial capital expenditure (CAPEX) for machinery and construction may seem manageable.

However, in a unique market like Nauru, a project’s long-term viability hinges not on the initial setup cost, but on its recurring, day-to-day operational expenditures (OPEX). A business plan that overlooks the nuances of OPEX in an island nation can quickly falter, turning a promising investment into a costly lesson.

This guide breaks down the key operational costs of running a solar module manufacturing plant in Nauru. The goal is to equip entrepreneurs and investors with the financial foresight needed to build a realistic and resilient business model, turning logistical challenges into a competitive advantage.

Understanding OPEX vs. CAPEX in Solar Manufacturing

Before delving into the details, it’s important to distinguish between two fundamental types of business expenses:

Capital Expenditures (CAPEX): These are major, one-time investments in physical assets. For a solar factory, this includes the land, the building, and the full suite of solar panel manufacturing equipment, such as stringers, laminators, and testers.

Operational Expenditures (OPEX): These are the ongoing costs required for the day-to-day running of the factory. OPEX includes everything from raw materials and employee salaries to electricity bills and shipping fees.

For a project in Nauru, this distinction is critical. While CAPEX can be estimated with relative certainty, OPEX is highly sensitive to local conditions. Underestimating factors like freight costs or utility expenses can severely impact profitability and cash flow.

Core OPEX Categories for a Nauruan Solar Plant

A successful financial model must account for several key operational costs, each with unique considerations in Nauru’s context.

1. Raw Material Procurement and Logistics

The single largest component of OPEX for any solar module manufacturer is the cost of raw materials. For a factory in Nauru, virtually all these materials must be imported, which introduces significant logistical complexity and cost.

Key materials include:

- Photovoltaic (PV) cells

- Tempered glass

- EVA (ethylene vinyl acetate) encapsulant

- Polymer backsheets

- Aluminum frames

- Junction boxes

Nauru-Specific Considerations:

- Freight Costs: Sea freight to Nauru from major manufacturing hubs in Asia is a substantial and recurring expense. This includes shipping, insurance, and local port handling fees.

- Inventory Management: Due to longer shipping times and less frequent vessel calls, a larger inventory of raw materials—a buffer stock—must be maintained. This ties up more working capital but is essential to ensure continuous production.

- Supplier Relations: Establishing reliable supply chains with vendors who have experience shipping to remote Pacific island nations is paramount.

2. Utilities: The Energy Cost Challenge

Solar module manufacturing is an energy-intensive process, with machines like laminators and cell testers consuming significant amounts of electricity. In Nauru, which has historically relied on imported diesel for power generation, electricity costs are among the highest in the world, making utility management a critical OPEX factor.

A factory’s financial plan must account for:

- High Cost per Kilowatt-Hour: The tariff for industrial electricity will be a major line item.

- Power Stability: Assessing the reliability of the local grid is crucial. Production stoppages due to power outages can be extremely costly.

- Strategic Mitigation: Many investors in such environments choose to build a captive solar power plant with battery storage for their factory. While this increases initial CAPEX, it drastically reduces and stabilizes long-term electricity OPEX, effectively hedging against volatile fuel prices.

3. Labor and Workforce Development

While automation plays a large role, a skilled workforce is still essential. The OPEX model must include salaries, benefits, and training costs.

Nauru-Specific Considerations:

- Local Workforce: The plan should prioritize hiring and training local Nauruan staff for operator and administrative roles. This involves investing in comprehensive training for technical staff to build the necessary skill sets.

- Expatriate Specialists: For highly specialized roles, such as senior process engineers or maintenance supervisors, hiring expatriates may be necessary. This introduces additional costs for salaries, housing, and travel.

- Efficiency and Productivity: For a semi-automated line of 20-50 MW capacity, a well-trained team of 25-30 employees is a typical benchmark.

4. Facility and Maintenance

The physical plant requires ongoing investment to remain operational and efficient.

- Building Upkeep: This includes routine maintenance, insurance, and security for the factory. Considering Nauru’s marine environment, materials and designs that resist corrosion are a wise long-term investment.

- Machinery Maintenance: Production equipment requires regular servicing and spare parts. Given the remote location, maintaining a substantial on-site inventory of critical spare parts is crucial. The cost of emergency air-freighting a single component from Europe or Asia can disrupt budgets and halt production for weeks.

Building a Preliminary OPEX Model for Nauru

To illustrate, consider a hypothetical 25 MW semi-automated production line in Nauru. The percentage breakdown of its annual OPEX might look something like this:

- Raw Materials: 65-70%

- Logistics & Freight (Inbound/Outbound): 10-15%

- Labor (Local & Expat): 5-8%

- Utilities (Electricity, Water, etc.): 5-7%

- Maintenance & Spares: 2-4%

- Other (Insurance, Admin, etc.): 1-3%

Note: These figures are illustrative and serve as a starting point. A detailed financial model is required for an actual investment decision.

This breakdown highlights that for a Nauruan plant, logistics costs command a much larger share of OPEX compared to a factory located near major industrial ports. A successful business plan must reflect this reality. Crafting a comprehensive business plan is therefore not just a formality, but a critical strategic exercise.

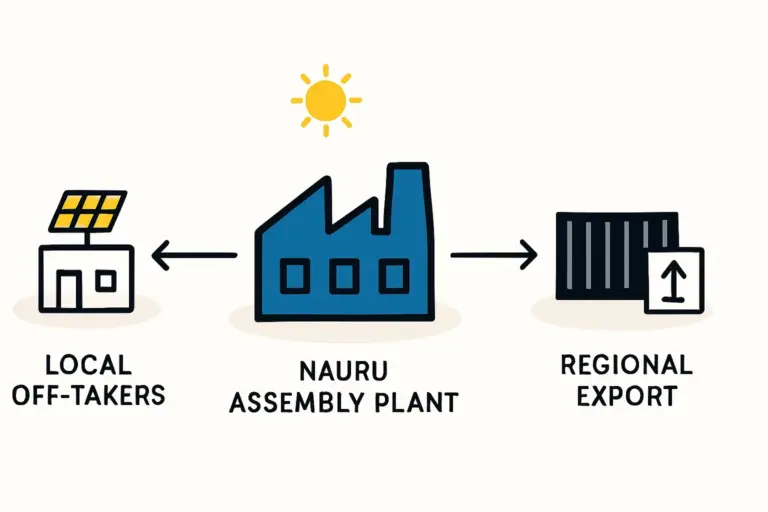

The Strategic Advantage of Local Manufacturing in an Island Nation

While the operational challenges are significant, so are the opportunities. A local manufacturing plant in Nauru can benefit from:

- Import Substitution: Reducing reliance on finished, imported solar modules, which carry their own significant shipping costs and tariffs.

- Energy Security: Contributing directly to Nauru’s goals for renewable energy independence.

- Regional Export Hub: Serving as a supplier for neighboring Pacific island nations, creating a new export industry for Nauru.

- Job Creation: Developing valuable technical skills within the local community.

Experience from J.v.G. turnkey projects in other locations with logistical challenges shows that meticulous early-stage planning is the single most important factor for long-term operational success.

Frequently Asked Questions (FAQ)

Q1: How much working capital is needed to cover initial OPEX?

For a standard project, 3-6 months of projected OPEX is a common benchmark for working capital. However, given Nauru’s extended supply chains, it’s prudent to budget for 6-9 months to cover raw material inventory and other costs before revenue stabilizes.

Q2: Can automation reduce the high labor costs?

Yes, a higher degree of automation can reduce the number of line operators. However, it increases the initial CAPEX and shifts the labor requirement toward a smaller number of more highly skilled (and potentially more expensive) maintenance technicians and engineers.

Q3: What is the biggest unforeseen operational cost for a factory in a location like Nauru?

The most common and disruptive unforeseen costs are typically related to logistics. This includes emergency air freight for a critical spare part when a machine breaks down or price spikes in container shipping. Building redundancy into the maintenance plan and supply chain is the best mitigation.

Q4: How do the factory building requirements differ for a tropical marine climate?

The factory’s building and layout requirements must account for high humidity and salt spray. This means specifying corrosion-resistant building materials and implementing strict climate control (HVAC systems) within the production and storage areas to protect sensitive materials like PV cells and laminating foils.

Conclusion: From Cost Estimation to a Viable Business Plan

Estimating operational expenditures for a solar module factory in Nauru is a complex but essential exercise. The unique challenges posed by logistics, utility costs, and workforce development require a financial model that is both detailed and conservative.

By anticipating these costs and building strategies to manage them—such as creating a robust spare parts inventory or investing in a captive power source—an investor can build a resilient and profitable enterprise. Creating this detailed financial model is a foundational step in the investment process.

For those seeking a structured approach, educational resources like the pvknowhow.com e-course can provide a comprehensive framework for navigating these planning stages with confidence.