Investors evaluating locations for a new manufacturing facility often prioritize factors like labor costs, logistics, and market access. In many promising regions, however, the most critical—and often underestimated—factor is the reliability and cost of electrical power. For a precision operation like a solar module factory, an unstable or expensive power supply can undermine the entire business case.

This is particularly true in St. Vincent and the Grenadines (SVG). While the nation offers strategic advantages, its energy infrastructure presents a unique set of challenges and opportunities that warrant careful analysis. Understanding the nuances of the local grid versus the potential of a self-contained power system is key to building a resilient and profitable manufacturing enterprise.

The Energy Landscape in St. Vincent and the Grenadines

As an island nation, SVG’s energy grid depends heavily on imported fossil fuels, primarily diesel, for electricity generation. This reliance has two significant consequences for any industrial consumer:

-

High Electricity Costs: The state-owned utility, VINLEC, is the sole electricity provider. Industrial tariffs are directly influenced by global fuel price volatility and typically range from US$0.30 to US$0.40 per kilowatt-hour (kWh). For a manufacturing plant with substantial energy needs, this is a major and unpredictable operational expense.

-

Grid Vulnerability: The energy infrastructure is susceptible to disruptions. Power outages can occur due to strain on generating capacity or, more frequently, from severe weather events like hurricanes and tropical storms common to the Caribbean.

For a prospective factory owner, these two points are not minor details; they are core business risks that must be addressed in the initial planning stages.

The Hidden Cost of Grid Instability in Manufacturing

In standard commercial operations, a power outage is an inconvenience. In precision manufacturing, it can be a financial catastrophe. A modern solar module production line relies on several time-sensitive and energy-intensive processes, such as cell stringing and lamination.

An abrupt loss of power during these critical stages can result in:

Material Waste: An entire batch of solar modules can be ruined, leading to a complete loss of expensive raw materials like solar cells, EVA film, and glass.

Production Delays: Downtime halts production schedules, delaying customer orders and impacting revenue.

Equipment Damage: Sudden power surges or cuts can damage sensitive and costly manufacturing equipment.

The cost of a single major outage—easily reaching tens of thousands of dollars in lost materials and productivity—is an unacceptably high risk for a new enterprise.

An Alternative Path: The Captive Solar-Plus-Storage System

To mitigate the risks of grid dependency, many industrial planners are turning to captive power systems. A captive power system is essentially a private, on-site power plant designed to serve a single facility. For a location like SVG with high solar irradiance, a solar-plus-storage system is the most sensible configuration.

This system consists of two primary components:

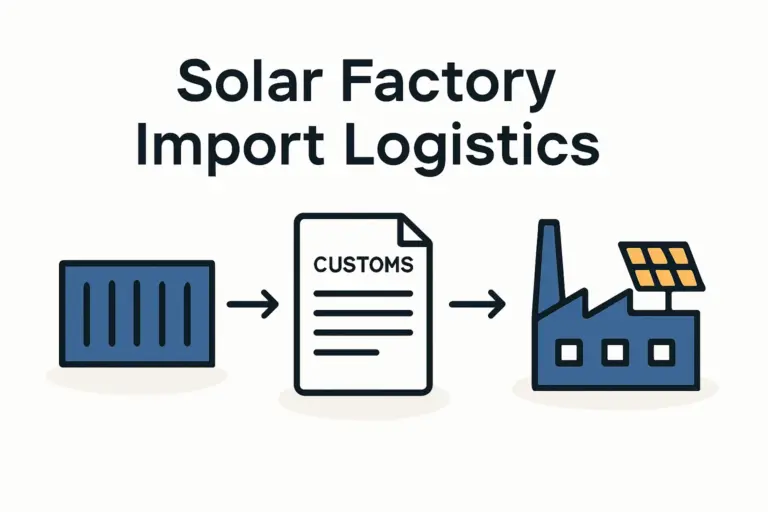

Solar Photovoltaic (PV) Array: Typically installed on the factory roof or adjacent land, the solar panels generate electricity during daylight hours.

Battery Energy Storage System (BESS): This system stores excess energy generated by the solar panels. It provides power during the night, on cloudy days, and most importantly, serves as an uninterruptible power supply (UPS) during a grid outage.

This setup transforms the factory from a passive electricity consumer into a highly energy-independent operation.

A Business-Focused Comparison: Grid Power vs. Captive Solar

When evaluating the two options, an investor must look beyond the initial investment to consider the long-term financial and operational implications.

Option 1: Relying on the VINLEC Grid

-

Financial Profile: Low initial capital expenditure (CapEx) for connection, but a high and unpredictable operational expenditure (OpEx) due to the US$0.30–$0.40/kWh tariff.

-

Risk Profile: High operational risk. The business is fully exposed to grid outages, production losses, and volatile global fuel markets that drive electricity prices.

Option 2: Investing in a Captive Solar + Storage System

-

Financial Profile: Significant initial CapEx for the system, but very low and predictable OpEx. The cost of generated electricity over the system’s 25-year lifespan is drastically lower than the grid tariff.

-

Risk Profile: Low operational risk. The factory is insulated from grid failures, ensuring production continuity. Energy costs are stabilized for decades, making financial forecasting more reliable.

A comprehensive financial analysis is a cornerstone of determining the overall investment requirements for a solar factory. This decision directly impacts long-term profitability and operational resilience.

Calculating the True Return on Investment (ROI)

A common mistake is calculating the ROI of a captive solar system based solely on electricity bill savings. While significant, this approach misses the most important financial benefit: the value of avoided downtime.

A proper analysis quantifies the cost of a full day of lost production. When that figure is multiplied by the potential number of outage days per year, the economic value of energy independence becomes clear. The investment in a solar-plus-storage system is not just an energy-saving measure; it is a form of production insurance.

Developing a detailed financial model that incorporates these variables is an essential, though complex, part of the strategic planning process for anyone learning how to start a solar module manufacturing business.

Frequently Asked Questions (FAQ)

What is a ‘captive power’ system?

A captive power system is a private power generation facility used exclusively by its owner for their own consumption. It provides independence from the public electricity grid, enhancing reliability and often lowering energy costs.

Is SVG’s climate suitable for solar power?

Yes, extremely so. As a Caribbean nation, St. Vincent and the Grenadines experiences high levels of solar irradiance year-round, making it an ideal location for high-yield solar energy generation.

How much space does a solar system for a factory require?

This depends on the factory’s energy consumption. A key advantage is that the expansive, flat roofs of most manufacturing plants provide ample, pre-existing space for solar panel installation, minimizing the need for additional land.

What about maintenance for a solar-plus-storage system?

Modern solar PV and battery systems require minimal maintenance. This typically involves periodic panel cleaning and routine inspections of electrical components, resulting in very low ongoing operational costs.

Can a factory sell excess power back to the grid in SVG?

This depends on the current policies of the utility, VINLEC. Some jurisdictions have net metering or feed-in tariff programs. An investor should always conduct due diligence on the latest local regulations to see if selling excess power is a viable option and potential revenue stream.

Next Steps in Your Infrastructure Planning

For any investor considering a manufacturing plant in St. Vincent and the Grenadines, or any market with a similar energy profile, the power strategy must be a primary consideration, not an afterthought. The choice between grid reliance and energy independence is a foundational decision that will impact everything from operational stability to long-term profitability.

A detailed feasibility study that models the costs, risks, and ROI of a captive power system is the indispensable next step. This analysis requires specialized knowledge of both solar technology and manufacturing operations. Resources like the structured e-courses at pvknowhow.com can provide a clear framework for evaluating these critical infrastructure decisions and building a robust, bankable business plan.