Entering a new market with a new industry raises a unique set of questions for any business leader. For entrepreneurs considering solar module manufacturing in Saint Vincent and the Grenadines, one of the most critical questions concerns the workforce: Is a local labor pool with the right skills available, and if not, how can one be developed?

Many assume that a high-tech manufacturing facility requires an existing base of specialized technicians. However, experience from turnkey projects in emerging markets tells a different story. The most successful ventures are often those that invest in building local talent from the ground up. This article explores the labor landscape in Saint Vincent and outlines a practical model for training a skilled, local team for a solar module production line.

Understanding the Local Labor Landscape in Saint Vincent

A sound human resources strategy starts with a thorough analysis of the local labor market. For Saint Vincent and the Grenadines (SVG), this means looking beyond raw statistics to understand the potential and the specific context of an island economy.

Labor Availability and General Skill Base

The economy of SVG has traditionally relied on agriculture and tourism. While these sectors may not seem directly related to photovoltaic manufacturing, they have cultivated a workforce with valuable transferable skills:

-

Manual Dexterity: Experience in agriculture and artisan crafts often translates to the fine motor skills required for handling solar cells and assembling components.

-

Service-Oriented Mindset: The tourism industry fosters an understanding of quality standards and client expectations, a valuable asset in a quality-controlled manufacturing environment.

-

Adaptability: A workforce accustomed to the seasonal and dynamic nature of tourism and agriculture is often highly adaptable to new processes and technologies.

Recent data on the national unemployment rate suggests a ready supply of people seeking stable, long-term employment. This creates an opportunity for a new manufacturer to become a preferred employer by offering structured training and career development.

Wage Expectations and Economic Context

A viable business plan must include realistic projections for labor costs. In Saint Vincent, hourly wages for semi-skilled labor are competitive compared to more developed nations. Typical wages for a production worker in a new manufacturing facility are in the range of XCD 10–15 per hour, with supervisors and team leaders earning a premium.

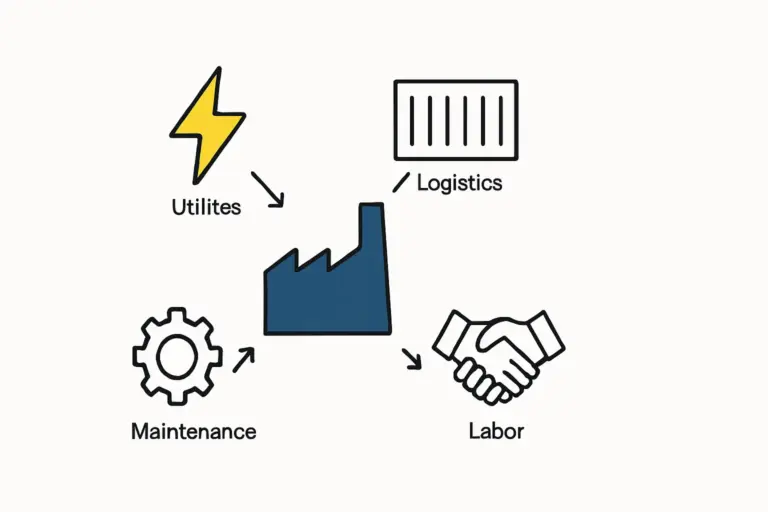

These figures are significantly lower than in North America or Europe, providing a distinct operational advantage. However, the goal should not be simply to minimize costs but to build a sustainable and motivated workforce. Offering wages slightly above the local average for similar roles, combined with a positive work environment and training, can dramatically reduce employee turnover and boost productivity. This analysis is a key factor in determining the overall labor and staffing requirements for a solar module factory.

Bridging the Skills Gap: A Practical Training Model

The key to success is not finding pre-trained solar experts in Saint Vincent but creating them. A modern, semi-automated solar production line is designed for operational simplicity. The most complex tasks are handled by machinery, while the human role focuses on process oversight, quality control, and material handling.

A proven method for building a competent local team is a structured, three-phase training program, often led by an experienced engineer from the equipment supplier.

Phase 1: Foundational Classroom Training (1-2 Weeks)

Before any employee touches a machine, they must understand the ‘why’ behind their work. This initial phase covers essential theoretical knowledge:

-

Introduction to Photovoltaics: A basic understanding of how a solar cell works and how modules generate electricity.

-

Manufacturing Process Overview: A step-by-step walk-through of the entire production line, from cell inspection to final testing.

-

Quality Standards and Principles: Introducing the concept of zero defects and the importance of each step in ensuring the final product’s longevity and performance.

-

Workplace Safety: Comprehensive training on safety protocols for handling glass, operating machinery, and electrical safety.

Phase 2: On-the-Job Machine Training (2-4 Weeks)

This is where theory becomes practice. Under the direct supervision of an experienced commissioning engineer, new operators learn their specific roles on the production equipment. For a turnkey production line, this training is an integral part of the installation process. Training focuses on:

-

Machine Operation: Learning the specific functions, start-up/shutdown procedures, and user interface of their assigned station (e.g., stringer, laminator).

-

Material Handling: Correct procedures for loading and unloading delicate materials like solar cells and glass.

-

In-Process Quality Checks: Training operators to become the first line of defense in quality control by identifying common defects.

Phase 3: Consolidation and Local Leadership Development (4-8 Weeks)

Once the team demonstrates basic operational competence, the focus shifts to consistency, speed, and sustainability. The external trainer gradually transitions from instructor to mentor. During this phase:

-

Production ramps up to target levels.

-

High-potential individuals are identified and trained as team leaders or supervisors.

-

These new local leaders are coached on how to train new hires, ensuring the facility can manage its own training needs in the future.

Experience from J.v.G. turnkey projects shows that with this structured approach, a completely new team can operate a 20-50 MW production line efficiently within three months of commissioning.

Key Production Roles and Their Specific Training Pathways

A typical small-scale solar factory requires fewer than 30 employees on the production floor. The critical roles are highly trainable.

The Stringer Machine Operator

The stringer solders solar cells together to form ‘strings.’ While the machine is automated, the operator’s role is crucial.

-

Core Skill: Attention to detail. The operator feeds cells into the machine and visually inspects the soldered ribbons for defects.

-

Training Focus: Understanding cell alignment, recognizing soldering defects, and performing basic machine troubleshooting. A deep technical understanding of the role of the stringer machine isn’t necessary for the operator but is essential for the supervising engineer.

The Lamination Operator

The laminator is the heart of the module assembly, bonding all the layers together under heat and vacuum.

-

Core Skill: Process discipline. The operator must follow a precise recipe and monitor the machine’s cycle.

-

Training Focus: Learning the correct lay-up procedure, understanding lamination cycle parameters (temperature, pressure, time), and identifying potential issues like air bubbles or delamination.

The Quality Control Inspector

A quality control inspector ensures that no defective product leaves the factory.

-

Core Skill: Meticulousness and objectivity. The inspector uses visual checks and testing equipment (like a sun simulator) to verify that every module meets standards.

-

Training Focus: Training focuses on visual inspection criteria for defects (scratches, cracks, misalignments) and operation of testing equipment. Their work is fundamental to achieving the high standards required for solar module quality control and certification.

Frequently Asked Questions (FAQ)

-

How many employees are needed to run a 20–50 MW solar factory?

A typical semi-automated line of this capacity can be run effectively with a team of 25–30 people per shift, including production operators, quality inspectors, material handlers, and one or two supervisors. -

Is it necessary to hire experienced engineers from overseas for the long term?

An experienced external engineer typically leads the initial commissioning and training phase. However, the goal of a structured training program is to develop a local management and technical team that can run the factory independently within 6 to 12 months. -

What is a realistic timeframe for a new team to achieve target production quality and output?

With a dedicated on-site trainer and a motivated team, a new workforce can typically reach target quality and 80% of target output within three months of the factory’s commissioning. -

Are there local vocational institutions in Saint Vincent that can assist with training?

Collaboration with local institutions like the SVG Community College can be beneficial for pre-screening candidates and providing foundational technical skills (e.g., basic electronics, workplace safety), creating a pipeline of trainable talent for the factory.

Conclusion: Building a Sustainable Asset

The feasibility of starting a solar module factory in Saint Vincent does not depend on finding a pre-existing pool of specialized labor. Instead, it depends on the investor’s commitment to building one. The local workforce has the adaptability and diligence needed for success in a modern manufacturing environment.

By implementing a systematic, hands-on training program, a company can transform available local talent into a skilled and efficient production team. This approach not only ensures operational excellence but also builds a strong, sustainable local enterprise that contributes directly to the economic development of the nation.

For business leaders exploring this venture, the next logical step is a deeper analysis of the entire setup process. Understanding the interplay between labor, machinery, and facility requirements is crucial for developing a comprehensive business plan. Our comprehensive guide to starting a solar factory provides further context on this journey.