An investor has a comprehensive business plan, secured initial funding, and identified a growing market for solar energy. The next step seems straightforward: build the factory. But the decision of where to build is one of the most critical in the entire venture. A strategic location can amplify success, while a poor choice can create persistent operational friction for years.

This article examines the essential criteria for selecting a solar module factory site, using Sierra Leone’s Freetown Special Economic Zone (SEZ) as a practical case study. It offers a framework for evaluating potential locations by balancing opportunities like government incentives against operational realities like infrastructure and labor.

The Strategic Importance of Site Selection

A manufacturing facility’s physical location influences nearly every aspect of its business performance. It dictates logistics costs, labor availability, and utility reliability, and determines the ease of access to both raw materials and end markets. For a solar module factory, where components are often imported and finished products distributed across a region, these factors are magnified.

A methodical site selection process isn’t just an administrative task; it is fundamental to managing risk and securing long-term profitability.

Evaluating Key Site Selection Criteria

When assessing potential locations, whether in West Africa or another emerging market, a structured evaluation should focus on several core areas. Each presents potential advantages and risks that must be carefully weighed.

Land and Infrastructure: The Foundation of Production

The physical site and its supporting infrastructure are the bedrock of any manufacturing operation. An ideal plot of land is useless without reliable access to essential services.

-

Land Acquisition and Zoning: Special Economic Zones (SEZs) often offer pre-zoned industrial land with streamlined acquisition or long-term lease processes. This can significantly reduce bureaucratic delays compared to acquiring private land, which may involve complex ownership verification and zoning approvals.

-

Utility Connections: A solar module assembly line requires a substantial and, most importantly, stable supply of electricity. In many regions, the public grid is unreliable. A critical assessment must include the cost and feasibility of on-site power generation (e.g., diesel generators or a dedicated solar-plus-storage system) as a primary or backup source. Access to clean water for module washing and other processes is another non-negotiable requirement.

Logistics and Market Access: The Supply Chain Lifeline

A factory’s success is directly tied to its ability to move goods in and out efficiently.

-

Proximity to Ports: Solar module manufacturing relies on imported raw materials like solar cells, glass, and aluminum frames. A location near a deep-sea port dramatically reduces inland transportation costs and lead times. This is a significant advantage for coastal locations like Freetown.

-

Inland Transport Network: The quality of roads and rail connections is crucial for bringing materials from the port to the factory and for distributing products to key domestic markets. Poor road conditions can lead to delays, damage to sensitive materials, and increased transportation costs. A thorough logistics analysis should map these routes and identify potential bottlenecks.

-

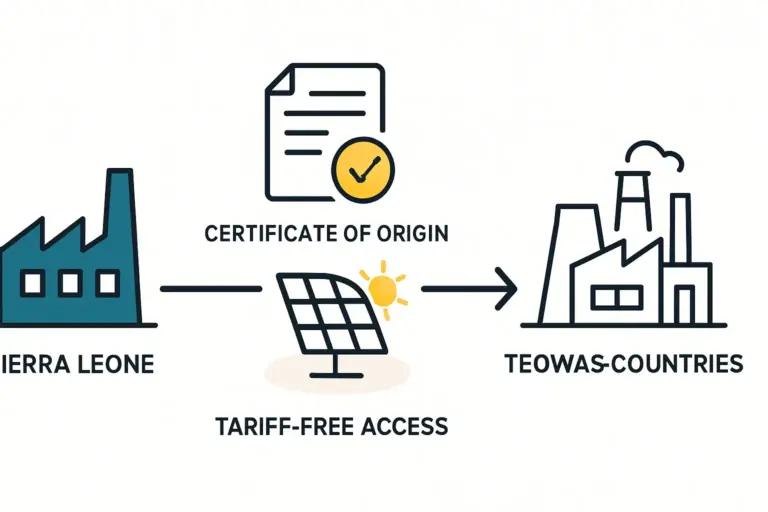

Access to Regional Markets: For export-oriented factories, membership in regional trade blocs like the Economic Community of West African States (ECOWAS) can provide preferential access to neighboring countries, expanding the potential customer base.

Labor and Skills: The Human Capital Equation

While module assembly is highly automated, it still requires a dedicated workforce. The availability and skill level of local labor is a key consideration.

-

Labor Pool Availability: A location with a large, youthful population can offer a sustainable source of labor. The focus, however, should be on trainability and work ethic rather than prior experience in solar manufacturing, which is often scarce in new markets.

-

Skills and Training: Assessing the local education landscape and the availability of technical skills is essential. Most successful new factories invest heavily in their own training programs, often with the support of their equipment suppliers. A key part of the initial plan involves budgeting for the process of hiring your first employees for a solar panel factory and developing their skills from the ground up.

Regulatory and Financial Environment: Navigating the Framework

The business climate and government policies can be a powerful tailwind or a significant headwind.

-

SEZ Incentives: Governments use SEZs to attract foreign investment by offering compelling benefits. These typically include tax holidays (e.g., zero corporate tax for several years), duty-free importation of machinery and raw materials, and simplified customs procedures. These incentives can significantly improve the financial viability of a new venture.

-

Political and Economic Stability: Investors require a predictable, stable environment. A track record of political stability, a clear legal framework for investment protection, and a government that actively promotes renewable energy are all strong positive indicators.

Case Study: Freetown’s Special Economic Zone (SEZ) as a Potential Site

Applying this framework to the Freetown SEZ in Sierra Leone reveals a compelling, if nuanced, picture for a potential solar module factory investor.

Advantages of the Freetown Location

The Freetown SEZ presents several strategic advantages rooted in its geography and government policy:

-

Prime Port Access: Situated near one of the largest natural deep-water harbors in the world, the Freetown SEZ offers excellent maritime logistics for importing components and exporting finished modules.

-

Strong Government Support: The government of Sierra Leone has actively promoted the SEZ to attract manufacturing investment, signaling a supportive policy environment.

-

Attractive SEZ Package: The zone provides a standard package of incentives, including tax holidays and duty-free imports, which directly lowers both initial capital expenditure and ongoing operational costs.

-

Regional Market Gateway: As a member of the Mano River Union and ECOWAS, a factory in Sierra Leone gains potential access to a wider West African market.

Potential Challenges and Mitigation Strategies

A realistic assessment must also account for the operational hurdles in the region.

-

Electricity Infrastructure: The national grid’s reliability is a significant concern, so any serious investment plan must include a robust on-site power solution. The cost of this independent power system must be factored into the total investment for a solar panel factory.

-

Inland Logistics: While port access is excellent, the road network connecting the port to the SEZ and other parts of the country can be challenging. A detailed logistics plan is necessary to ensure the efficient and safe movement of goods.

-

Skilled Labor Development: As with many emerging markets, finding experienced solar technicians locally is unlikely. The business model must therefore include a comprehensive training program to build the required skills within the local workforce. Based on experience from J.v.G. turnkey projects, a well-structured training plan can bring a new team to full productivity within a few months.

A Comparative Look: Regional Alternatives

No site selection decision should be made in a vacuum. It’s prudent to compare the primary candidate location against regional alternatives, such as industrial zones in Nigeria or Ghana.

-

Nigeria: Offers a vast domestic market and a more developed industrial base but also presents higher levels of competition, complex port logistics, and its own set of infrastructure challenges.

-

Ghana: Boasts a reputation for political stability, a relatively stable power sector, and efficient ports. Its investment incentives and cost structures may differ, requiring a direct comparison against the Freetown SEZ package.

This comparative analysis helps ensure the chosen location offers the optimal balance of benefits for the project’s specific goals.

A Structured Approach to Your Decision

The complexity of site selection demands a methodical process, not an intuitive one. A recommended approach is to create a decision matrix or scorecard. List the key criteria—logistics, labor, utilities, costs, incentives—and assign a weight to each based on its importance to your business model. Then, score each potential location against every criterion.

This disciplined approach removes emotion from the decision and provides a clear, data-driven justification for the final choice. This process is a foundational element in the comprehensive guide on how to start a solar panel factory.

Frequently Asked Questions (FAQ)

What exactly is a Special Economic Zone (SEZ)?

An SEZ is a geographically designated area where business and trade laws differ from the rest of the country. They are created to attract foreign direct investment, boost manufacturing, and create jobs by offering incentives like tax breaks, duty-free imports, and streamlined regulations.

How critical is a stable electricity supply for a module factory?

It’s absolutely critical. Automated production lines, such as stringers and laminators, are highly sensitive to power fluctuations, which can cause equipment damage, material waste, and costly production downtime. A reliable power source is non-negotiable.

Can a local workforce with no prior solar experience be trained effectively?

Yes. Modern solar module assembly is a process-driven operation. With a structured training program, typically led by machine suppliers and an experienced production manager, a motivated local workforce can be trained to operate machinery efficiently and safely in a matter of weeks to months.

How long does a typical site selection process take?

A thorough site selection process, from initial research to final decision and land acquisition, can take anywhere from 6 to 12 months. This includes desk research, multiple site visits, negotiations with authorities, and detailed due diligence on infrastructure and legal matters. Rushing this stage is a common but avoidable mistake.