For many entrepreneurs, the solar industry appears dominated by massive, multi-gigawatt factories. Yet one of the most significant and underserved markets requires a completely different approach.

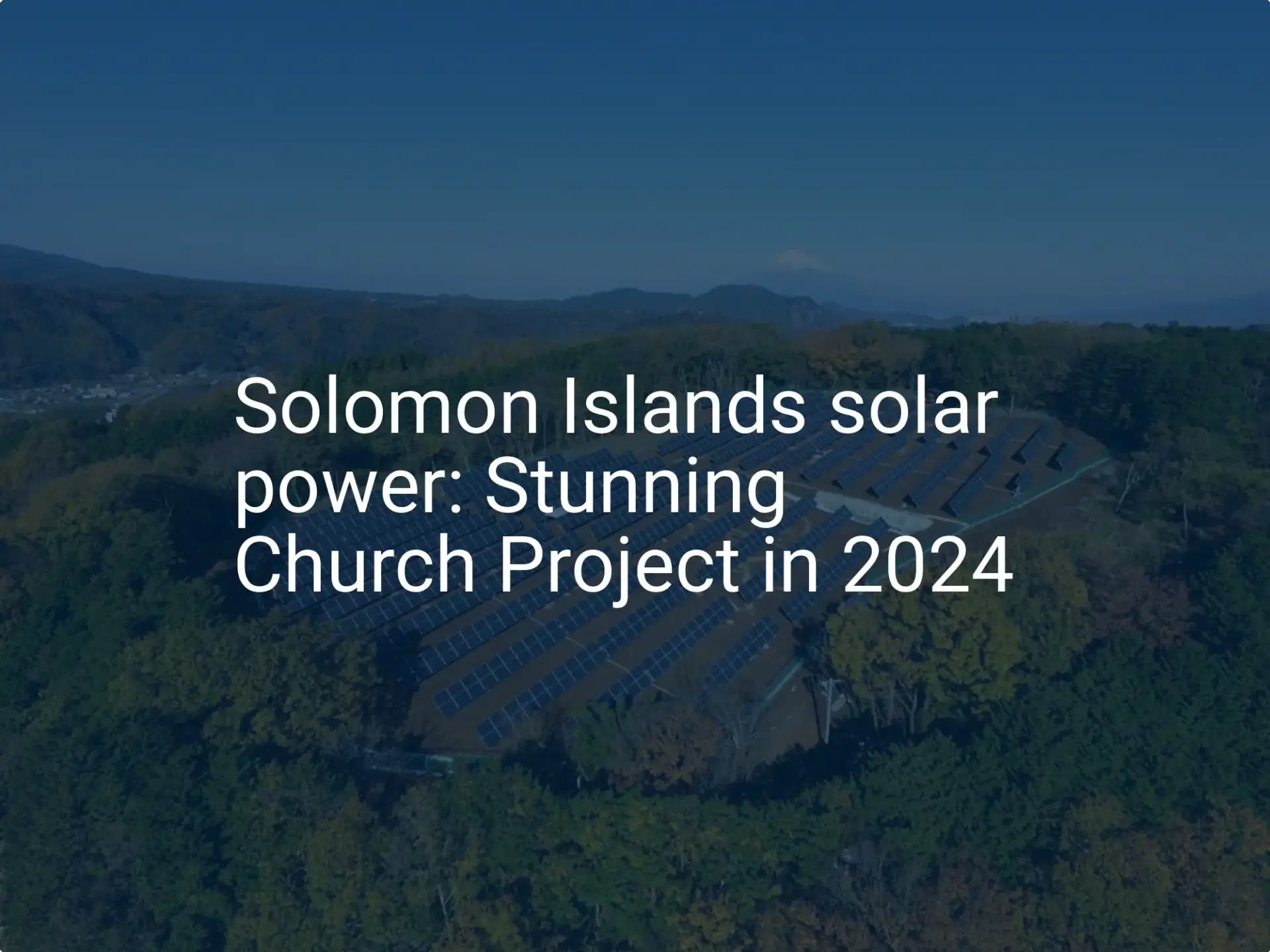

Consider a nation composed of nearly 1,000 islands, like the Solomon Islands, where only 12% of the population has access to the national electricity grid. For the remaining 88%, reliable power is not a matter of convenience but a foundation for education, healthcare, and economic survival.

This scenario—common across Oceania, Africa, and parts of Asia—presents a powerful business case not for importing solar modules, but for manufacturing them locally. This article examines the strategic advantages of establishing a domestic solar panel production facility to serve remote atolls and off-grid communities: a market defined by unique challenges and immense potential.

The Energy Paradox in Island Nations

Archipelagos and regions with dispersed rural populations face a fundamental energy paradox. They often have abundant solar resources but suffer from extreme energy poverty due to geography. The conventional model of importing finished solar modules from major manufacturing hubs breaks down under these conditions.

Using the Solomon Islands as a case study, the challenges become clear:

-

Geographic Fragmentation: With a population of around 680,000 spread across 992 islands, a centralized grid is economically and technically unfeasible for most of the country.

-

Logistical Hurdles: Importing panels involves international shipping, followed by complex and costly inter-island logistics, often on small boats.

-

High Costs: Import duties, such as the 15% tariff on solar panels in the Solomon Islands, combined with multi-stage transportation costs, significantly inflate the final price for the end user.

These factors create a market where imported products are often too expensive, prone to damage in transit, and difficult to source consistently. This is precisely the environment where a local manufacturing operation can thrive.

Why Importing Fails and Local Production Succeeds

For any entrepreneur evaluating this market, understanding the limitations of the import model is the key to recognizing the opportunity. A local production facility transforms systemic weaknesses into strategic strengths.

Overcoming Logistical and Financial Barriers

A domestic factory fundamentally changes the supply chain. Instead of importing fragile, finished modules, a manufacturer imports raw materials in bulk containers—a process that is far more efficient and less prone to damage.

The key advantages include:

-

Reduced Import Tariffs: Raw materials often carry lower import duties than finished goods, providing an immediate cost advantage.

-

Supply Chain Control: A local facility can maintain inventory and produce modules based on demand, avoiding the long lead times and uncertainties of international shipping.

-

Lower Transportation Costs: Shipping materials to one central factory is far more economical than distributing finished panels to hundreds of remote locations from an overseas port.

-

Local Job Creation: Establishing a manufacturing plant creates skilled local employment, a factor that often attracts government support and aligns with national development goals.

Starting a solar panel manufacturing business in this context is less about competing on global price-per-watt and more about building a resilient, cost-effective local supply chain.

Product Specifications for Rural Electrification

Off-grid communities do not need the large, high-wattage panels designed for utility-scale solar farms. Their requirements are specific, and a local factory can be configured to produce exactly what the market needs.

Module Size and Power Output

The core demand is for smaller modules, typically in the 80W to 150W range. These are perfectly suited for:

-

Individual Households: Powering lights, charging mobile phones, and running small appliances.

-

Community Buildings: Energizing schools for evening study or powering lights and refrigerators in a health clinic.

-

Small Businesses: Enabling services like mobile phone charging stations, village cinemas, or refrigeration for shops.

A local producer can dedicate its solar panel manufacturing machine setup to these specific sizes, optimizing production and meeting the precise needs of its customers.

Durability and Environmental Resistance

Modules destined for remote islands must be exceptionally robust. A key consideration in coastal and marine environments is resistance to salt mist corrosion, which can degrade inferior-quality panels rapidly. A local manufacturer can specify and build modules with materials suited to these harsh conditions, such as stronger frames and salt-resistant junction boxes. This approach yields a more durable product than a generic imported alternative.

Reaching the End User: Key Distribution Channels

A successful local manufacturing strategy hinges on a clear understanding of its sales channels. In off-grid markets, these channels are often different from conventional retail. A comprehensive solar panel manufacturing business plan must account for a multi-channel approach.

Government and Institutional Tenders

Governments and development banks are major buyers of off-grid solar systems. National energy policies, like the Solomon Islands’ goal for 100% renewable energy by 2030, often result in large-scale tenders for rural electrification projects. A local manufacturer is perfectly positioned to bid on and win these contracts.

Partnerships with NGOs and Aid Organizations

Non-governmental organizations (NGOs) and international aid agencies are deeply involved in deploying solar solutions for healthcare, education, and disaster relief. They prioritize reliable local partners who can provide durable products and long-term support.

Collaboration with Local Cooperatives and Churches

In many rural communities, cooperatives and church networks are the most trusted institutions. Partnering with them provides a direct and credible channel to reach thousands of households and community leaders.

Frequently Asked Questions about Local Solar Manufacturing for Off-Grid Markets

What is the typical investment for a small-scale factory?

While costs vary, a semi-automated production line with a capacity of 20–50 MW per year requires a structured investment. This scale is often well-suited for serving a national or regional off-grid market. The investment primarily covers machinery, facility preparation, and initial raw material inventory.

How complex is the manufacturing process?

Modern solar manufacturing has become highly modular. With a turnkey solar panel production line, the entire process—from sourcing machinery to training local staff—is systematic. This approach allows an entrepreneur without a deep technical background to enter the industry with expert guidance and proven processes.

Can a local factory compete with large international manufacturers?

Competition is not based on the raw cost-per-watt. A local factory competes on ‘landed cost’ and value. By eliminating international shipping costs, import duties on finished goods, and the risk of damage, the final price to the customer can be highly competitive. Furthermore, the ability to provide customized, durable products and local support creates a value proposition that large exporters cannot match.

From Concept to a Viable Business

The business case for local solar module manufacturing in off-grid markets is not based on sentiment, but on sound economic and logistical principles. It is a model that turns the inherent challenges of remote geographies into a protective moat for the business.

By aligning production with specific market needs and leveraging diverse distribution channels, an entrepreneur can build a profitable enterprise that delivers transformative social and economic impact.

Evaluating this opportunity requires careful planning and a deep understanding of the technical and financial demands. For those ready to explore this compelling market segment, building a detailed financial model and operational plan is the logical next step.