One of the most compelling ironies in the solar industry is the need for a stable, high-quality power supply to manufacture solar modules—the very devices designed to generate power.

For an entrepreneur planning a factory in a region with an unreliable public grid, this poses a fundamental challenge. A momentary power surge or outage during a critical production step can halt operations, damage expensive equipment, and waste valuable materials.

This article explores how a solar module factory in a location like Somalia can achieve complete energy independence. We detail a practical infrastructure solution that transforms a significant operational risk into a strategic advantage, ensuring consistent production regardless of external grid conditions. This approach is not a theoretical model; it is based on real-world engineering solutions implemented in J.v.G. turnkey projects.

The Critical Importance of Uninterrupted Power in Solar Module Manufacturing

A solar module production line is a sequence of highly synchronized, energy-sensitive machines. The laminator, for instance, requires a continuous, stable power supply to maintain precise temperatures and pressures for over 20 minutes per cycle. A sudden loss of power during this process can render an entire batch of modules worthless. Similarly, the automated stringers that solder solar cells together rely on consistent energy to maintain their robotic precision.

The challenge is magnified in many promising markets. According to the World Bank, grid reliability in Sub-Saharan Africa is a significant constraint on economic growth, with frequent and prolonged outages being the norm. For a manufacturing business, this unreliability translates directly into financial losses and operational uncertainty. Relying on such an infrastructure is not a viable strategy for a high-tech manufacturing facility.

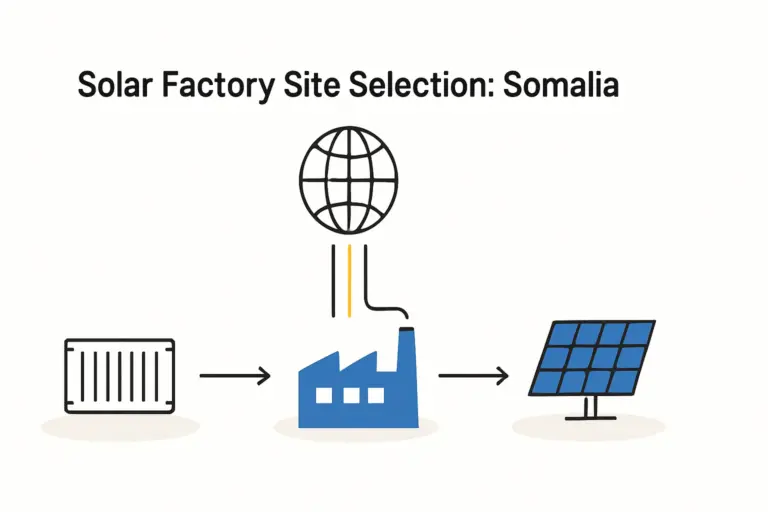

A Case Study: Powering a Solar Factory in Somalia

Consider the scenario of establishing a new solar module factory in Somalia. The region offers exceptional solar irradiation—a key resource for the products being manufactured. However, the local electrical grid lacks the stability required for continuous industrial operations.

The goal was to design a power system that would completely isolate the factory from the unpredictable public grid, guaranteeing round-the-clock operations. This required creating a self-contained, private power plant, often referred to as a ‘captive’ power system.

Designing a Resilient Power Infrastructure Solution

The solution is an integrated system built on three pillars, designed for maximum reliability and efficiency. This approach turns the factory itself into a self-sufficient energy hub.

The Three-Pillar Approach to Energy Independence

Pillar 1: The Captive Solar Power Plant

The factory’s primary power source is a solar PV system installed directly on its roof. This system is sized not only to meet the factory’s daytime operational demand but also to generate surplus energy. Given Somalia’s high Global Horizontal Irradiance (GHI), a well-designed rooftop solar array can produce a substantial amount of electricity, forming the economic and logistical core of the factory’s energy strategy.

Pillar 2: Battery Energy Storage System (BESS)

The excess energy generated during peak sunlight hours is stored in a large-scale Battery Energy Storage System (BESS). This stored energy is then used to power the factory during the night or on overcast days, ensuring a seamless, uninterrupted power supply. The BESS acts as an energy reservoir, decoupling the factory’s operations from the intermittency of solar generation.

Pillar 3: Diesel Generator as a Final Backup

As a final safeguard, a diesel generator serves as the third layer of protection. It is designed to engage only in rare emergencies, such as during extended periods of unusually poor weather or when the main system requires maintenance. This component is not for daily use but is a crucial part of a comprehensive risk mitigation strategy, ensuring the factory can operate under almost any condition.

The Business Logic Behind the Investment

An independent power system requires a significant upfront investment. However, a detailed analysis reveals a compelling business case. When this infrastructure is integrated into the initial solar panel manufacturing business plan, it becomes clear that the cost is justified by the immense value it protects.

The return on this investment is realized through:

-

Elimination of Downtime: The cost of lost production hours, wasted raw materials, and potential equipment damage from grid failures is completely avoided.

-

Predictable Energy Costs: The factory is insulated from volatile electricity tariffs and fluctuating fuel prices, leading to stable, predictable operational costs.

-

Enhanced Bankability: A facility with guaranteed energy independence is a much lower-risk proposition for investors and financial institutions. It demonstrates robust planning and a clear path to consistent revenue generation.

This strategic approach transforms a potential liability into a core strength, providing the operational stability necessary to compete effectively.

Frequently Asked Questions (FAQ)

Why not just rely on the public grid and a large generator?

Relying on a diesel generator as a primary backup to an unstable grid is often financially and operationally inefficient. The high and unpredictable cost of diesel fuel, coupled with the maintenance demands and noise of a constantly running generator, makes it a less sustainable solution than a primary solar-plus-storage system.

How large does the solar and battery system need to be?

The required capacity is directly linked to the factory’s production volume and the specific energy consumption of its equipment. A thorough energy audit of all solar panel manufacturing machines is necessary to engineer a correctly sized system. For a typical 20–50 MW production line, the captive power system would likely be in the range of several hundred kilowatts to over a megawatt.

Is this solution only for regions with no grid at all?

No. This model is highly effective for any region where the grid is either unreliable or expensive. By generating its own power, a factory gains a competitive edge through lower, more stable energy costs and the guaranteed production quality that comes from uninterrupted operations.

Conclusion: From Infrastructure Challenge to Competitive Advantage

Establishing a manufacturing facility in an emerging market presents unique challenges, but as this case demonstrates, they can be overcome with careful planning and sound engineering. An unstable power grid, which may seem like an insurmountable obstacle, is a problem that can be solved with a self-sufficient power infrastructure.

By understanding each step of the solar panel manufacturing process and its energy requirements, an entrepreneur can build a factory that is not just viable but resilient. This turns a local disadvantage into a global competitive advantage, characterized by operational stability, cost predictability, and complete control over the production environment. With the right guidance, even the most complex infrastructure challenges become manageable parts of a successful business plan.