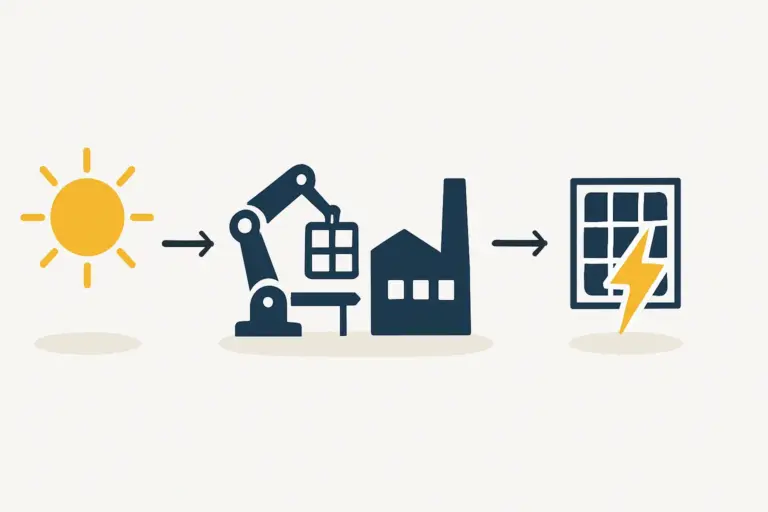

Imagine the scene: your new solar module factory is operational. The multi-million dollar investment is humming to life as the production line begins its precise, automated dance. Suddenly, the lights flicker and die. The hum of machinery gives way to an unsettling silence. In South Africa, this scenario is more than a hypothetical risk—it’s a daily operational reality known as loadshedding.

For an entrepreneur entering the capital-intensive field of solar manufacturing, planning for an unstable power grid isn’t a secondary concern—it’s fundamental to the business model. An unreliable power supply poses a direct threat to production uptime, equipment integrity, and ultimately, the financial viability of the entire investment.

This guide outlines the specific challenges loadshedding presents to a solar module factory and maps out a strategic approach to engineering energy resilience from day one.

The True Cost of Unreliable Power in Manufacturing

The impact of loadshedding extends far beyond the inconvenience of a temporary shutdown. For a manufacturing business, the costs are direct, cumulative, and can severely undermine profitability.

Based on 2023 data from the Council for Scientific and Industrial Research (CSIR), South Africa experienced loadshedding on an estimated 332 days of the year. The economic consequences are staggering; a Stats SA survey revealed that 85% of businesses report production downtime and increased operational costs.

For a solar module manufacturer, these costs manifest in several critical ways:

-

Material Waste: The solar module production process involves stages that are highly sensitive to interruption. A typical lamination cycle, for instance, heats and cures materials like EVA film over a 15-20 minute period, drawing 60-120 kW of stable power. A sudden power loss mid-cycle can render all materials in the machine—glass, cells, EVA, and backsheet—unusable. The result is direct material loss and hours of non-productive time spent cleaning and resetting the equipment.

-

Equipment Damage: Sensitive electronics and precision instruments are vulnerable to the power surges and dips that often accompany grid outages. A stringer machine, which uses 10-15 kW to perform thousands of delicate soldering connections, can suffer damage to its soldering heads from such fluctuations, leading to costly repairs and extended downtime.

-

Reduced Throughput and Efficiency: Unplanned stops and starts disrupt the flow of production. Each interruption requires a time-consuming reset and recalibration of the line, eroding the factory’s overall output and efficiency.

Why a Standard Diesel Generator is Not Enough

The most common response to power instability is to install a diesel generator. While a necessary component of a comprehensive strategy, relying on a generator as the sole backup solution is a flawed and expensive approach for a modern manufacturing facility.

The primary limitations include:

-

High Operational Cost: Running a diesel generator can be four to five times more expensive than using grid electricity, equating to R5-R7 per kWh compared to an average grid tariff of R1.5-R2 per kWh. This dramatically increases the factory’s operational expenditure (OPEX).

-

Delayed Switchover Time: A generator requires time—from seconds to over a minute—to start up and stabilize before it can take the load. For sensitive machinery like a laminator or stringer, this brief interruption is more than enough to ruin a production cycle and cause the problems outlined above.

A generator alone cannot provide the seamless, instantaneous power required to protect equipment and prevent material loss.

Engineering a Resilient Hybrid Energy Strategy

A robust and cost-effective solution involves designing an integrated, hybrid power system tailored to the factory’s specific energy needs. This approach treats energy as a core part of the production infrastructure, not an afterthought.

The Role of Solar PV for Self-Consumption

A solar module factory has a significant advantage: its large, flat roof is perfect for a solar PV installation. This system can generate a substantial portion of the factory’s electricity demand during daylight hours, directly reducing reliance on the unstable and costly grid. Not only does this provide cleaner energy, but it also hedges against rising utility tariffs.

Integrating Battery Energy Storage Systems (BESS)

The cornerstone of a truly resilient system is a Battery Energy Storage System (BESS). A BESS acts as an industrial-grade Uninterruptible Power Supply (UPS), providing two key functions:

-

Instantaneous Backup: When the grid fails, the BESS takes over the load instantly (within milliseconds). This seamless transition ensures that all production machinery continues to operate without interruption, completely eliminating the risk of a ruined lamination cycle or damage to sensitive electronics.

-

Energy Shifting: The BESS can store excess solar energy generated during the day. This stored energy can then power the factory during evening loadshedding periods or peak tariff times, further reducing energy costs.

The Strategic Use of a Diesel Generator

In this hybrid model, the diesel generator is repositioned as a tertiary backup, used only for prolonged outages that exceed the BESS capacity, such as multi-day grid failures or extended periods of low solar generation. This dramatically reduces its run-time, fuel consumption, and maintenance costs, making it a cost-effective safety net rather than a primary, expensive solution.

This integrated approach is a core consideration in projects undertaken by J.v.G. Technology, where designing for grid instability in emerging markets is a standard part of planning a turnkey solar manufacturing line.

Factoring Energy Resilience into Your Business Plan

An integrated energy system is a strategic asset that must be included in the project’s financial modeling from the outset. While it adds to the initial investment, the return is realized through:

-

Guaranteed Production Uptime: The factory can operate continuously through loadshedding, meeting production targets and contractual obligations.

-

Reduced Operational Costs: Lower electricity bills from solar self-consumption and minimized use of expensive diesel fuel.

-

Elimination of Waste: Prevention of material and product losses caused by power interruptions.

-

Enhanced Investor Confidence: A business plan that proactively solves the grid stability challenge is inherently de-risked and more attractive to funders.

Production schedules can also be optimized around energy availability—for example, by planning the most energy-intensive processes for periods of peak solar production to maximize the use of self-generated power.

FAQ: Addressing Common Questions on Power Stability

How is this hybrid system different from just using a large generator?

A generator alone cannot protect your machinery from the initial power cut. The switchover delay, however brief, is the critical point of failure. A hybrid system with a BESS provides instantaneous, uninterrupted power, using the generator only as a long-duration backup—which is both safer and more cost-effective.

How much battery storage does a factory need?

The required BESS capacity depends on several factors: the total power consumption of your machinery, the duration of the loadshedding periods you wish to cover (e.g., 2-4 hours), and the size of your rooftop solar PV system. A detailed energy audit is the first step in correctly sizing the system.

Is an independent power system a requirement for a modern solar factory?

While it’s not a strict requirement in regions with a stable national grid, it should be considered a non-negotiable component of the business plan in markets like South Africa or other countries with known grid deficiencies. It moves the factory from a position of vulnerability to one of operational control.

Conclusion: Building a Future-Proof Manufacturing Operation

For entrepreneurs looking to establish a solar module manufacturing plant in a region affected by loadshedding, energy resilience is not an optional upgrade—it is a prerequisite for success. By moving beyond reactive solutions like a standalone generator and embracing a proactive, integrated hybrid power strategy, a new facility can guarantee operational continuity, protect its valuable equipment, and control its energy costs.

Planning for an independent power supply from day one transforms a major operational risk into a strategic advantage, ensuring your investment is built on a foundation of stability and prepared for sustained growth.