An entrepreneur planning to establish a solar module factory in Sri Lanka faces a critical question: where will the raw materials come from? While the nation has an ambitious goal to achieve 70% renewable energy by 2030, its industrial base for producing specialized solar components is still developing. This reality creates a complex decision for any new market entrant.

This analysis explores the practicalities of sourcing a solar module’s bill of materials in Sri Lanka, weighing the potential for local procurement against the reliability of established international supply chains. Striking the right balance is key to building a resilient and cost-effective manufacturing operation.

The Anatomy of a Solar Module: A Bill of Materials

Before assessing supply chains, it’s essential to understand the primary components that make up a finished solar panel. Each part has specific technical requirements that dictate its manufacturing complexity and, by extension, its likely origin.

The main raw materials include:

- Aluminum Frame: Provides structural integrity and protects the edges of the laminate.

- Solar Glass: A highly transparent, low-iron, tempered glass that protects the solar cells while maximizing light transmission.

- Solar Cells: The core semiconductor devices that convert sunlight into electricity.

- Encapsulant (EVA): Ethylene Vinyl Acetate films used to laminate the components, providing adhesion and insulation.

- Backsheet: A multi-layered, polymer-based material that protects the rear of the module from moisture and UV radiation.

- Junction Box: An enclosure on the back of the module that houses the bypass diodes and provides the connection point for the electrical output.

Assembling these materials requires a precise solar panel manufacturing process to ensure durability, safety, and performance over a 25-year lifespan.

Evaluating Sri Lanka’s Local Sourcing Potential

For a new manufacturer, leveraging local suppliers offers advantages like reduced shipping costs, shorter lead times, and contributing to the local economy. However, the technical readiness of Sri Lanka’s industry requires careful evaluation for each component.

Aluminum Frames: A Promising Starting Point?

Sri Lanka has an established aluminum extrusion industry that serves the construction sector. On the surface, this presents a viable opportunity for local sourcing, as frames can account for a significant portion of a module’s material cost.

However, solar module frames require very specific tolerances, high-quality anodization for corrosion resistance, and precise machining for assembly. A prospective manufacturer would need to conduct rigorous due diligence to confirm that local extruders can consistently meet these stringent solar-grade specifications. In many turnkey projects in emerging markets, initial operations begin with imported frames while local suppliers are gradually qualified.

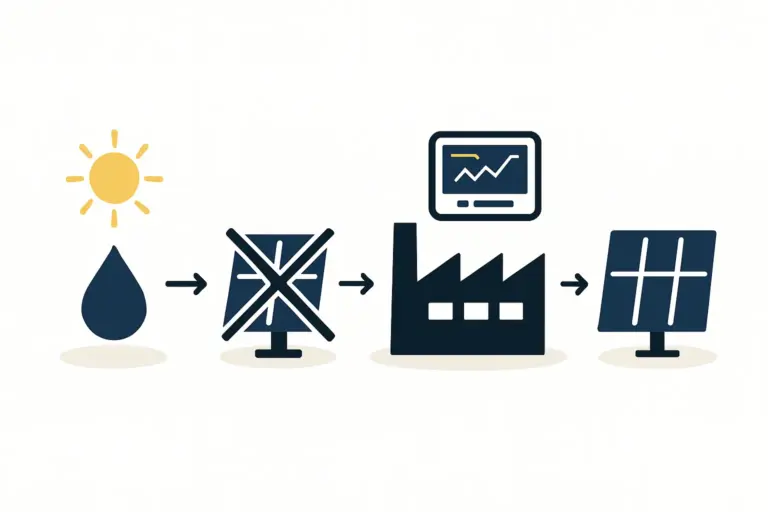

Solar Glass: A Technical Hurdle

Solar glass is not ordinary glass. It requires a specialized manufacturing process to reduce iron content, which increases transparency, and then tempering to enhance its strength against environmental factors like hail.

The capital investment for a solar-grade glass manufacturing plant is substantial, and Sri Lanka currently has no facility that produces this specific type of glass. For the foreseeable future, solar glass will need to be imported for any local module assembly operation.

Junction Boxes and Specialized Polymers

Components like junction boxes, encapsulants (EVA), and backsheets are products of highly specialized electronics and chemical industries.

- Junction Boxes: While Sri Lanka has a growing electronics assembly sector, junction boxes for solar modules require specific IP (Ingress Protection) ratings and high-quality bypass diodes to ensure safety and long-term reliability. It is unlikely that a local supplier could meet these needs without significant investment and certification efforts.

- EVA and Backsheets: These are specialty polymer films produced by a small number of global chemical companies. Sourcing these materials will depend entirely on imports.

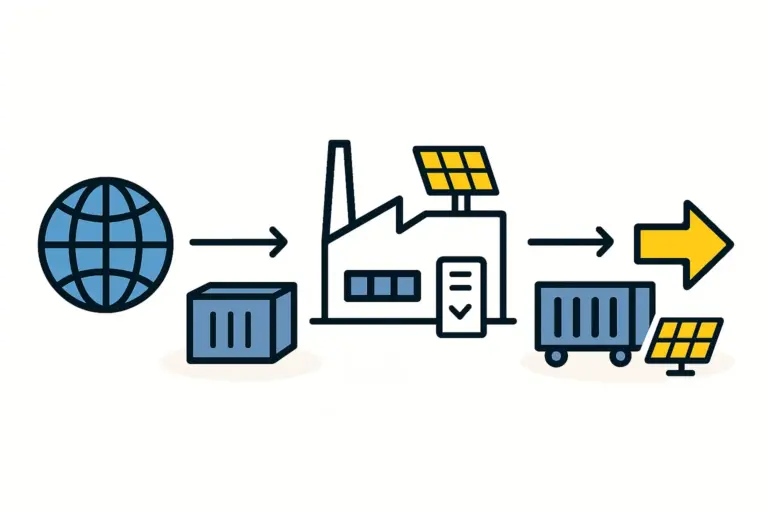

The Reality of Import Dependency for New Manufacturers

For any new solar module assembly plant in Sri Lanka, the most practical initial strategy is to rely on imports for nearly all key components. The global supply chain, primarily centered in China and other parts of Asia, is mature, competitive, and capable of supplying complete module kits.

This import-led strategy has several business implications that a solar panel manufacturing business plan must address:

- Logistical Strengths: Sri Lanka’s strategic location and the efficiency of the Port of Colombo are significant advantages, facilitating reliable and cost-effective shipping routes.

- Supplier Vetting: Establishing relationships with reputable international suppliers is critical for ensuring consistent quality and avoiding disruptions.

- Working Capital: Longer lead times for sea freight require higher inventory levels of raw materials, which must be factored into working capital planning.

- Import Duties and Taxes: Government policies on imported components will directly impact the final cost of production and require thorough investigation.

A Phased Approach: Balancing Local Value with Global Realities

Based on experience setting up factories in similar economic environments, a phased sourcing strategy is the most prudent path.

-

Phase 1: Full Importation. Begin operations by importing complete, pre-qualified bills of materials from a single, reliable supplier. This minimizes quality risks and allows the factory to focus on mastering the assembly process and achieving initial certifications.

-

Phase 2: Gradual Localization. Once production is stable, the manufacturer can begin to explore and qualify local suppliers for less technically sensitive components. Aluminum frames are often the first candidate, followed by packaging materials. This approach allows for a controlled transition that does not compromise final product quality.

This methodical strategy ensures a smooth start, building a resilient supply chain that combines the quality assurance of global leaders with the eventual economic benefits of local partnerships.

Frequently Asked Questions (FAQ) on Solar Material Sourcing

Where do the solar cells themselves come from?

Solar cells are the most technologically complex component. Their production requires massive capital investment and specialized expertise. Nearly all module assemblers worldwide, including those in Sri Lanka, import solar cells from large, dedicated manufacturers in China, Southeast Asia, or Europe.

Can using local materials affect module certification?

Absolutely. To achieve international certifications like those from the IEC (International Electrotechnical Commission), every single component in the module must meet specified standards. Any locally sourced material, such as an aluminum frame, would need to undergo rigorous testing to ensure it does not compromise the overall quality and safety of the final product.

How much do raw materials contribute to the final cost of a solar module?

Raw materials typically represent 60–70% of the total manufacturing cost of a solar panel. This underscores why a robust and cost-effective sourcing strategy is a primary driver of a plant’s profitability.

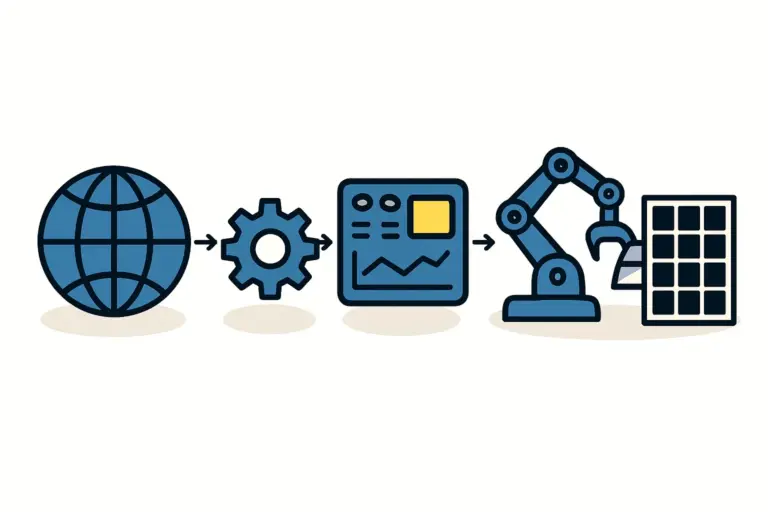

What equipment is needed to assemble these materials?

Assembling these components requires a series of specialized machines. A typical production line includes a stringer machine for soldering cells, a laminator for bonding the layers, and various testing units like a sun simulator. A full list of required solar panel manufacturing machine units is a core part of the initial factory planning.

Conclusion: Strategic Sourcing as a Competitive Advantage

For an entrepreneur investigating how to start a solar panel manufacturing business in Sri Lanka, the message is clear: while increasing local content is a long-term goal, the immediate reality is a reliance on global supply chains. The initial focus should be on establishing strong relationships with international suppliers to ensure quality and consistency.

A successful operation will be built not on an idealistic vision of 100% local sourcing from day one, but on a pragmatic, phased approach that leverages Sri Lanka’s logistical advantages while methodically developing local partnerships. This strategic view of the supply chain is a cornerstone of building a sustainable and competitive manufacturing enterprise in the country’s growing solar industry.