Starting a solar module factory in a landlocked country poses a unique set of logistical puzzles. While coastal nations benefit from direct sea access, a manufacturer in a country like Switzerland must engineer a supply chain that is both resilient and cost-effective.

With careful planning, however, this perceived geographic disadvantage can become a strategic advantage built on efficiency and precision. This article explores the challenges and solutions for managing a solar supply chain from a landlocked, non-EU country, using Switzerland as a practical example. The principles discussed here apply to entrepreneurs in any landlocked region considering entry into solar manufacturing.

The Central European Dilemma: Landlocked and Outside the EU

Switzerland’s position in the heart of Europe is both a strength and a challenge. It is surrounded by major economic powers and boasts world-class road and rail infrastructure. However, it lacks its own seaports, meaning all ocean-freighted goods must first enter a neighboring country.

Additionally, as a non-EU member, goods crossing its borders are subject to customs procedures not required for trade between EU states. For a solar manufacturer, this means raw materials sourced from Asia—such as solar cells, tempered glass, and backsheets—must navigate a multi-stage journey. This journey typically begins at a major European port like Rotterdam, Antwerp, Genoa, or Hamburg before continuing overland to the Swiss factory.

The primary challenge is not distance, but coordination. Every step, from the ocean vessel’s arrival to the final delivery truck, involves handoffs, potential delays, and administrative requirements. All of which must be expertly managed to avoid disrupting the production line.

Sourcing Strategy: A Global and Regional Mix

An effective supply chain begins with strategic sourcing. A Swiss solar manufacturer will almost never source all components from a single region. The strategy is usually a hybrid model that balances cost, quality, and logistical efficiency.

Sourcing from Asia

The bulk of the core components are often sourced from established suppliers in Asia for reasons of cost-effectiveness and scale. These include:

- Solar Cells: The most critical and technologically sensitive component.

- Solar Glass: A heavy, high-volume material requiring specialized handling.

- Backsheets and EVA Encapsulant: Essential for module durability and performance.

These materials are typically shipped in standard 40-foot containers via sea freight, the most economical method for long-distance transport of heavy goods.

Sourcing from Europe

For other components, sourcing from European suppliers offers significant advantages, including reduced shipping times, lower transport costs for smaller quantities, and simplified customs in some cases. These often include:

- Aluminum Frames: Sourcing regionally can reduce transit damage and allow for more flexible inventory management.

- Junction Boxes: Specialized electronic components where European quality and proximity can be a deciding factor.

Understanding the origin of all the raw materials for solar panels is a critical first step in designing an efficient inbound logistics plan.

The Inbound Logistics Framework: From Port to Production Line

Experience from J.v.G. turnkey projects shows that a successful logistics framework for a Swiss manufacturer rests on a three-part solution: strategic port selection, optimized inland transport, and the use of a bonded warehouse.

-

Strategic Port Selection

The choice of seaport is critical. Rotterdam (Netherlands) is frequently chosen for its high efficiency, deep integration with Europe’s inland waterway and rail networks, and extensive experience handling goods destined for Switzerland. While ports like Genoa (Italy) are geographically closer, the efficiency of the ‘Northern Range’ ports often results in more reliable transit times. -

Optimized Inland Transport

Once containers are offloaded, they must travel overland. Switzerland’s excellent rail network makes it a highly reliable and environmentally sound option for transporting heavy goods from ports like Rotterdam. Rail transport is less susceptible to the traffic congestion and driver shortages that can affect road haulage. -

The Bonded Warehouse Solution

This is perhaps the most crucial element for managing cash flow and customs. A bonded warehouse (or customs warehouse) is a secure facility where imported goods can be stored, managed, and even undergo minor processing without the payment of import duties.

A J.v.G. client in Switzerland successfully used this model, establishing a bonded warehouse near Basel, a major logistics hub. Materials arriving from the port are transported directly to this warehouse under a customs transit procedure. The manufacturer pays import duties only when materials are moved from the warehouse to the factory for production. This ‘just-in-time’ approach to duty payment significantly improves working capital, a key consideration in the solar factory investment cost. This strategy also influences the required on-site storage capacity within the solar factory layout.

Navigating Customs and Administrative Hurdles

Operating outside the EU customs union adds a layer of administrative complexity. Every shipment entering Switzerland from an EU port must be accompanied by a transit document, typically a T1 document. This document allows goods that have not yet cleared customs in the EU (non-Union goods) to move through the EU to the Swiss border under customs control.

Managing this documentation accurately is non-negotiable. Errors can lead to significant delays and fines. This is why it is standard practice for solar manufacturers to partner with experienced freight forwarders and customs brokers. These partners manage the entire process, ensuring that declarations are correct, transit documents are in order, and goods clear the border smoothly. This professional partnership is a vital operational investment.

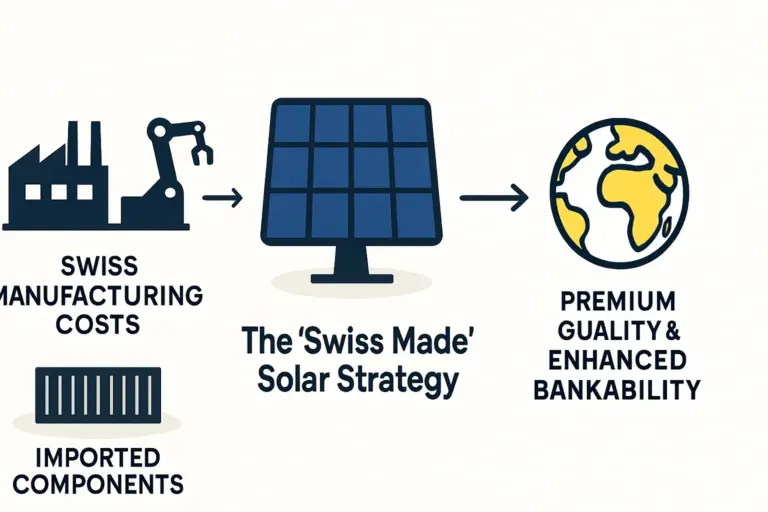

Outbound Logistics: Capitalizing on ‘Swiss Made’ Quality

Ultimately, the value of the final product justifies the logistical effort. A ‘Swiss Made’ solar module commands a premium in the global market, appealing to customers who prioritize quality, durability, and high performance.

The outbound logistics strategy mirrors the inbound process, but in reverse.

- For EU Markets: Finished modules are transported by road or rail, with proper export and import declarations filed to enter the EU market.

- For Global Markets (Middle East, Africa): Modules are transported back to a major European port for shipment to their final destination.

The higher value of the finished product helps absorb these sophisticated logistical costs, making them a manageable part of the overall cost structure.

Key Takeaways for Entrepreneurs in Landlocked Regions

The Swiss model provides a valuable blueprint for any entrepreneur planning a solar factory in a landlocked location. The core principles are universally applicable:

- Map Your Supply Lines: Identify the most efficient seaports and inland transit routes to your location.

- Utilize Customs Warehousing: Investigate the possibility of using bonded warehouses to defer import duties and improve cash flow.

- Forge Expert Partnerships: Do not attempt to manage international freight and customs alone. Engage reputable logistics partners from the outset.

- Balance Your Sourcing: Combine global sourcing for cost-effective core components with regional sourcing for flexibility and speed.

Frequently Asked Questions

What is a bonded warehouse?

A bonded warehouse is a building or secured area where dutiable goods can be stored or processed without payment of duty. It operates under the supervision of the country’s customs authority. This allows an importer to defer payment of taxes and duties until the goods are removed for consumption.

Why not source all raw materials from Europe to simplify logistics?

While sourcing from Europe simplifies transportation, the global market for key solar components like high-efficiency cells is dominated by manufacturers in Asia. For a new manufacturer to be cost-competitive, sourcing these core materials globally is often a necessity. The goal, then, is to optimize logistics for this global reality.

How much do these logistics add to the final cost per module?

Logistics and customs are a significant operational cost and must be carefully modeled in the business plan. While the exact percentage varies based on shipping rates and volumes, it is a key factor that distinguishes a landlocked operation from a coastal one. The premium price for a high-quality, ‘Swiss Made’ product is designed to accommodate these higher operational costs.

Can these principles be applied in a landlocked African or Asian country?

Absolutely. The fundamental strategy of identifying the most efficient port, optimizing the inland corridor (whether by rail or road), and utilizing customs tools like bonded zones or warehouses is a globally applicable approach for managing supply chains in any landlocked region.

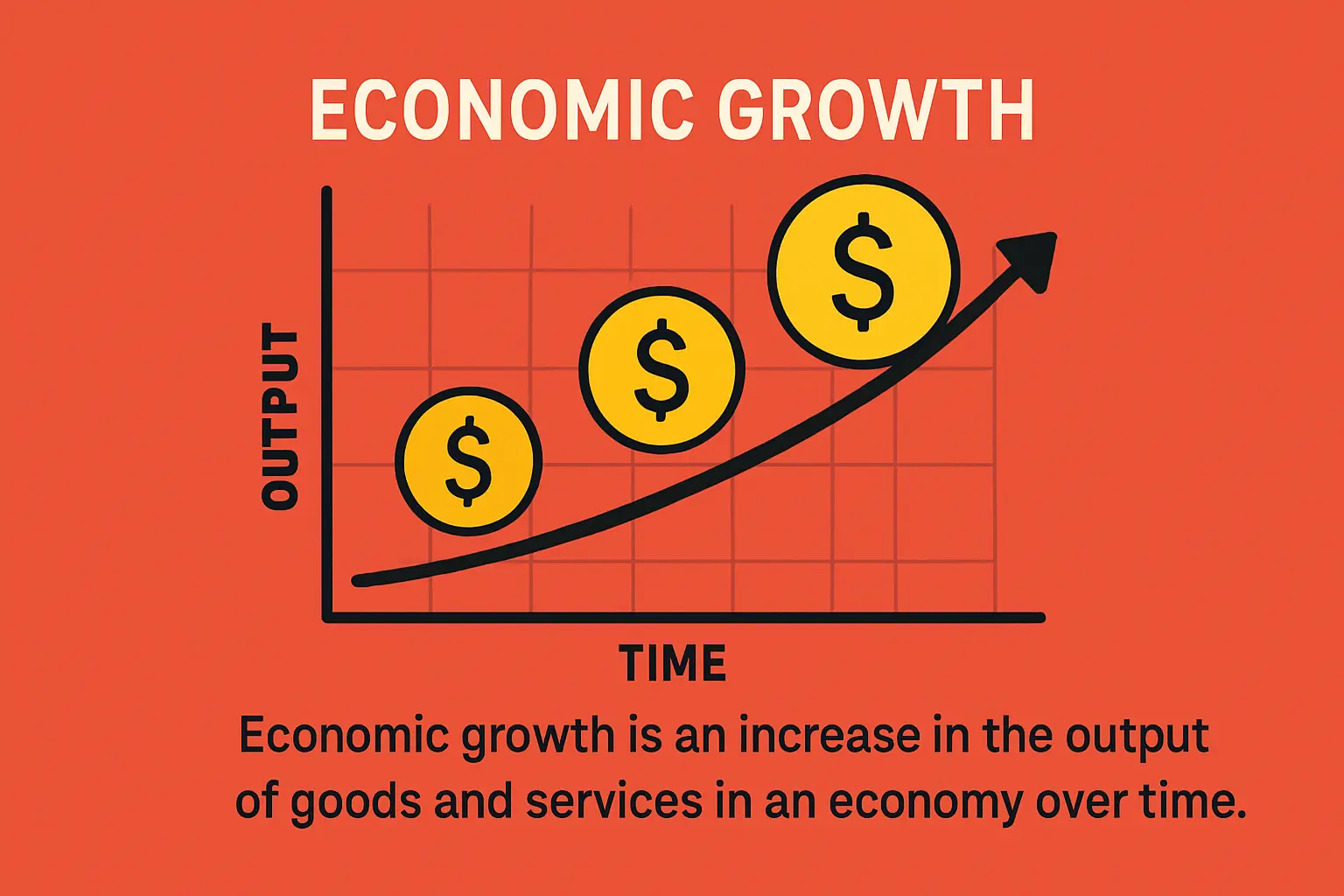

From Logistical Challenge to Competitive Advantage

A landlocked location is not an insurmountable barrier to success in solar manufacturing. By viewing logistics not as a problem but as an integral part of the business strategy, a manufacturer can build a highly efficient and resilient operation. Understanding the complete solar panel manufacturing process from material sourcing to final export allows for precise planning. With the right partnerships and a well-designed framework, a factory located far from any coast can compete effectively on the global stage, turning its geographic uniqueness into a hallmark of operational excellence.